Aluminum alloy sliding valve

A technology of aluminum alloy and aluminum alloy materials, which is applied in the field of slide valves, can solve problems such as easy wear, affect the service life of slide valves, and large friction, and achieve the effects of enhanced corrosion resistance, excellent oxidation effect, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

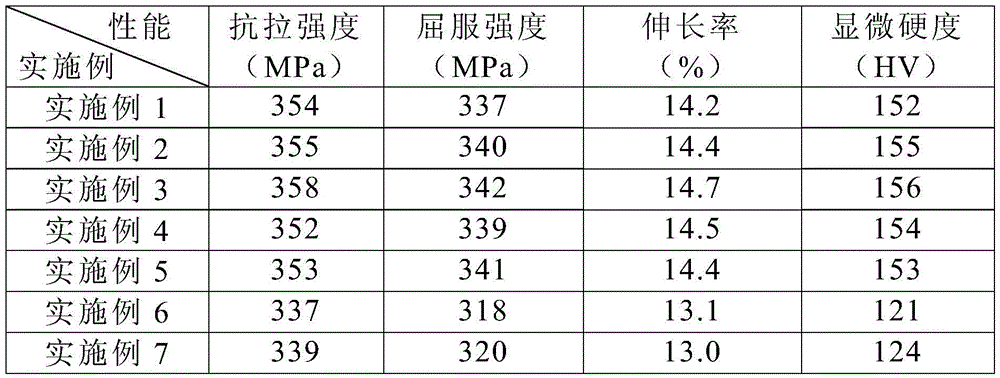

Examples

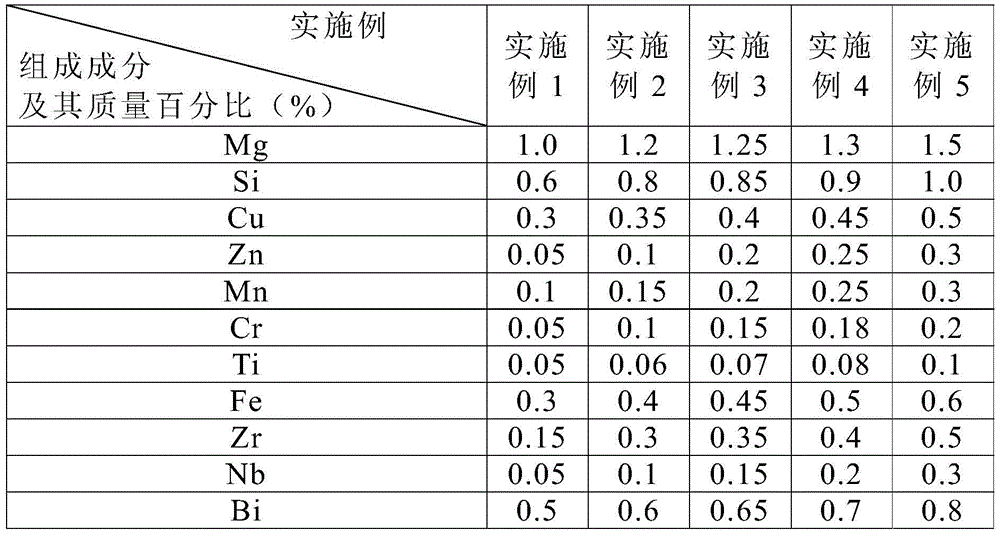

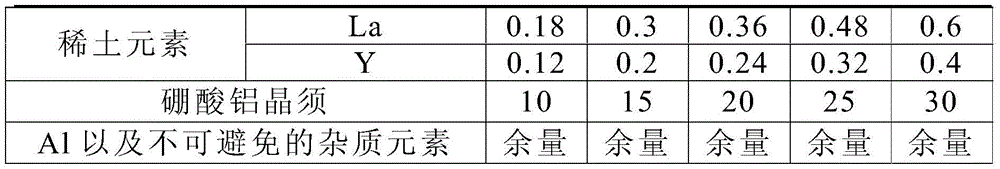

Embodiment 1

[0036] First, according to the composition and mass percentage of the aluminum alloy of Example 1 in Table 1, batching and smelting, ultrasonic vibration was applied during the smelting process, the ultrasonic power of the ultrasonic vibration was 500W, and the frequency was 20kHz. After smelting into molten aluminum, carry out slag removal, degassing and refining, and then carry out slag removal after standing still.

[0037]Then pour the aluminum liquid after deslagging into the pressure chamber, fill it into the cavity of the mold at an injection speed of 80L / min and pour it, so that the aluminum liquid is solidified and formed under the injection pressure of 60MPa to obtain valve body castings and valve core castings . Then the obtained valve body castings and valve core castings are subjected to heat treatment. The heat treatment includes solution treatment and double-stage aging treatment. The solution treatment is gradient solution treatment. Keep warm for 10 minutes, ...

Embodiment 2

[0040] First, according to the composition and mass percentage of the aluminum alloy of Example 2 in Table 1, batching and smelting, ultrasonic vibration was applied during the smelting process, the ultrasonic power of the ultrasonic vibration was 600W, and the frequency was 23kHz. After smelting into molten aluminum, carry out slag removal, degassing and refining, and then carry out slag removal after standing still.

[0041] Then pour the aluminum liquid after deslagging into the pressure chamber, fill it into the cavity of the mold at the injection speed of 82L / min and pour it, so that the aluminum liquid is solidified and formed under the injection pressure of 65MPa to obtain valve body castings and valve core castings . Then the obtained valve body castings and valve core castings are subjected to heat treatment. The heat treatment includes solution treatment and double-stage aging treatment. The solution treatment is gradient solution treatment. Keep warm for 9 minutes,...

Embodiment 3

[0044] First, according to the composition and mass percentage of the aluminum alloy of Example 3 in Table 1, batching and smelting, ultrasonic vibration was applied during the smelting process, the ultrasonic power of the ultrasonic vibration was 650W, and the frequency was 25kHz. After smelting into molten aluminum, carry out slag removal, degassing and refining, and then carry out slag removal after standing still.

[0045] Then pour the aluminum liquid after deslagging into the pressure chamber, fill it into the cavity of the mold at an injection speed of 85L / min and pour it, so that the aluminum liquid is solidified and formed under the injection pressure of 70MPa to obtain valve body castings and valve core castings . Then heat-treat the obtained valve body castings and valve core castings. The heat treatment includes solution treatment and double-stage aging treatment. The solution treatment is gradient solution treatment. Keep warm for 8 minutes, keep warm for 8 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com