High-temperature-resistant ceramic material and preparation method thereof

A technology of high-temperature-resistant ceramics and raw materials, applied in the field of high-temperature-resistant ceramic materials and their preparation, can solve problems such as brake failure, brake heat generation, brake discs affecting brake performance, etc., achieve uniform heating, excellent heat transfer capacity, and avoid embrittlement The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

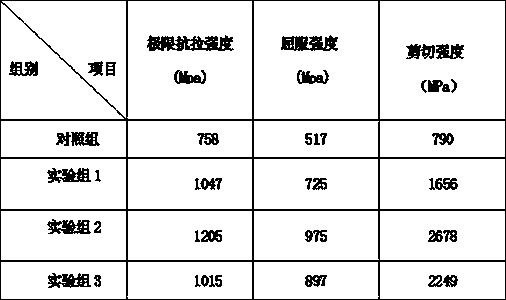

Examples

Embodiment 1

[0036] A high-temperature-resistant ceramic material, comprising the following raw materials in proportions by weight: 208 parts of nano-zirconia, 25 parts of tungsten carbide powder, 20 parts of mica powder, 18 parts of iron oxide powder, and 10 parts of four-acicular zinc oxide whiskers , 50 parts of aluminum nitride powder, 2 parts of scandium oxide powder, 30 parts of cobalt powder, 10 parts of molybdenum carbide powder, 22 parts of silicon carbide whiskers, 6 parts of aluminum borate whiskers, 3 parts of nano iridium and 3 parts of yttrium oxide powder.

[0037] A preparation method of a high temperature resistant ceramic material comprises the following steps:

[0038] 1) Mix 208 parts of nano zirconium dioxide, 25 parts of tungsten carbide powder, 20 parts of mica powder, 18 parts of iron oxide powder, 10 parts of four needle-shaped zinc oxide whiskers, 30 parts of cobalt powder, 10 parts of molybdenum carbide powder, silicon carbide 22 parts of whiskers, 6 parts of alu...

Embodiment 2

[0047] A high-temperature-resistant ceramic material, comprising the following raw materials in parts by weight: 233 parts of nano-zirconia, 36 parts of tungsten carbide powder, 22 parts of mica powder, 20 parts of iron oxide powder, and 14 parts of four-acicular zinc oxide whiskers , 53 parts of aluminum nitride powder, 6 parts of scandium oxide powder, 70 parts of cobalt powder, 15 parts of molybdenum carbide powder, 28 parts of silicon carbide whisker, 10 parts of aluminum borate whisker, 6 parts of nano-iridium and 8 parts of yttrium oxide powder.

[0048] A preparation method of a high temperature resistant ceramic material, comprising the following steps:

[0049] 1) Mix 233 parts of nano zirconium dioxide, 36 parts of tungsten carbide powder, 22 parts of mica powder, 20 parts of iron oxide powder, 14 parts of four-needle zinc oxide whiskers, 70 parts of cobalt powder, 15 parts of molybdenum carbide powder, silicon carbide 28 parts of whiskers, 10 parts of aluminum borat...

Embodiment 3

[0058] A high-temperature-resistant ceramic material, comprising the following raw materials in parts by weight: 222 parts of nano-zirconia, 30 parts of tungsten carbide powder, 21 parts of mica powder, 19 parts of iron oxide powder, and 12 parts of four-acicular zinc oxide whiskers , 52 parts of aluminum nitride powder, 4 parts of scandium oxide powder, 50 parts of cobalt powder, 13 parts of molybdenum carbide powder, 25 parts of silicon carbide whiskers, 8 parts of aluminum borate whiskers, 4 parts of nano-iridium and 5 parts of yttrium oxide powder.

[0059] A preparation method of a high temperature resistant ceramic material, comprising the following steps:

[0060] 1) Mix 222 parts of nano zirconium dioxide, 30 parts of tungsten carbide powder, 21 parts of mica powder, 19 parts of iron oxide powder, 12 parts of four-needle zinc oxide whiskers, 50 parts of cobalt powder, 13 parts of molybdenum carbide powder, silicon carbide 25 parts of whiskers, 8 parts of aluminum borat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com