Conductive polyurethane sole material

A sole material, polyurethane technology, applied in soles, footwear, clothing, etc., to achieve environmental friendliness, improve electrical conductivity, and improve affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

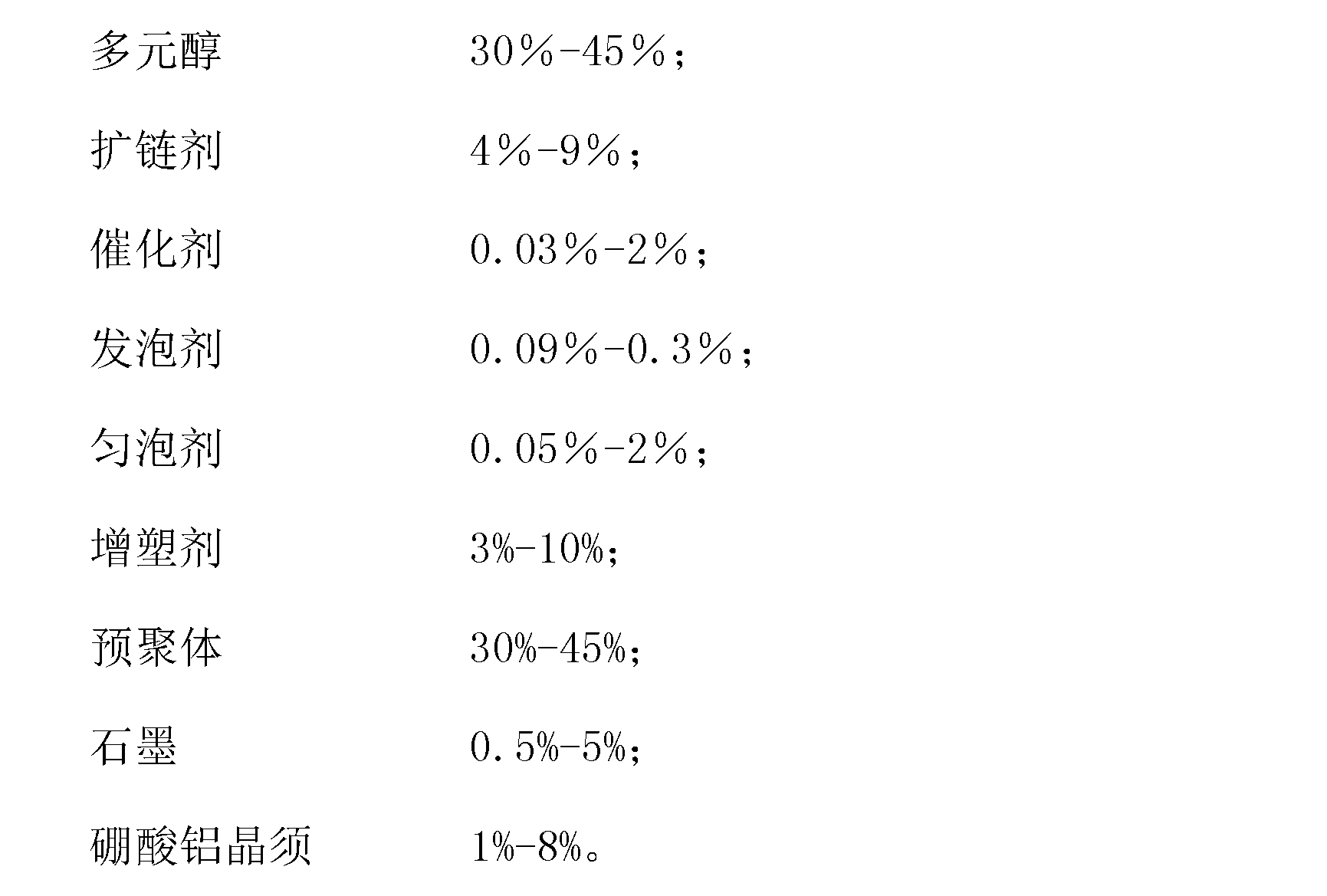

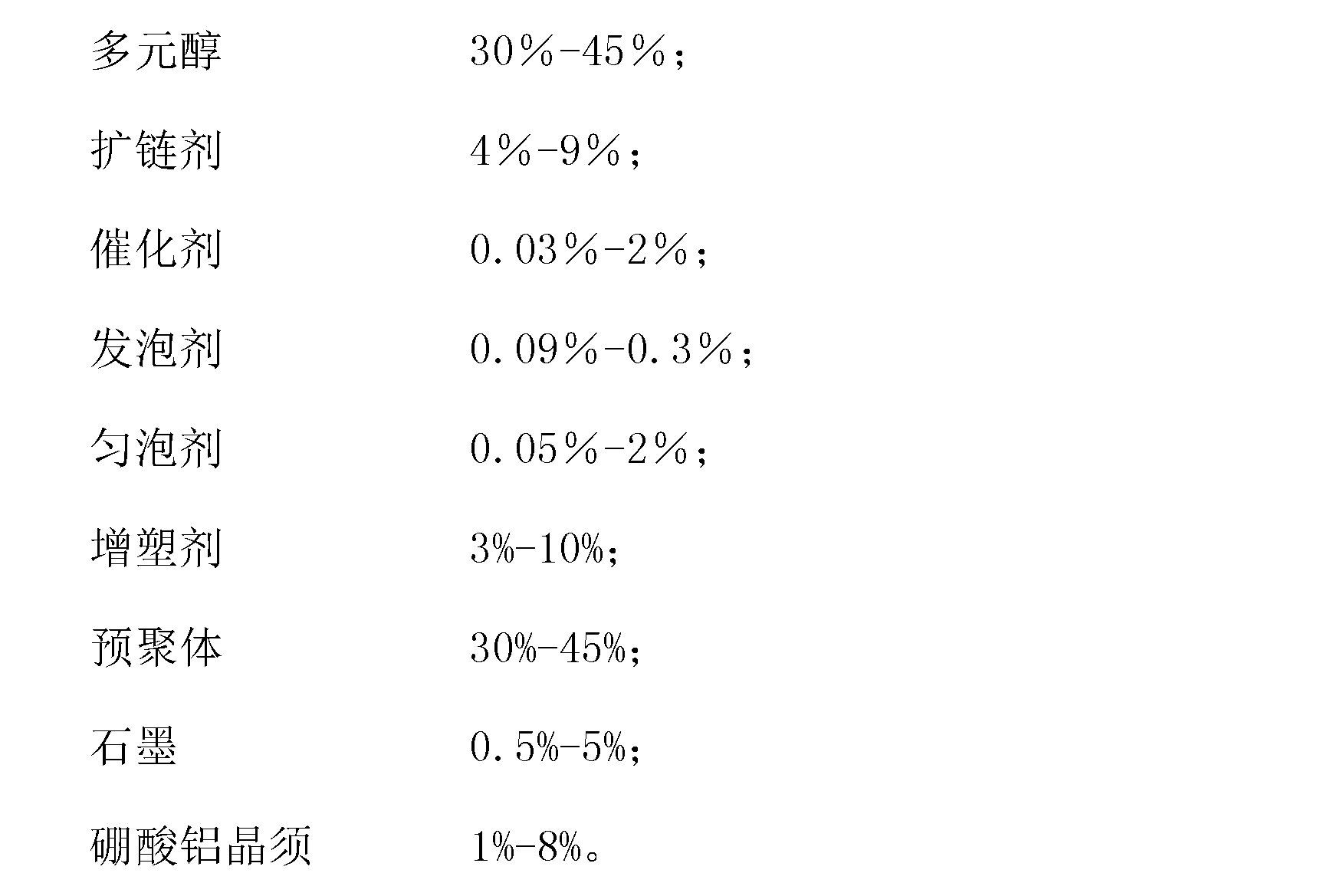

Method used

Image

Examples

Embodiment 1

[0018] The polyoxypropylene ether polyol is dehydrated, and the specific operation method is: put the polyol in a vacuum oven at 95-105°C, and dry it for 2-4 hours.

[0019] Get dehydration-treated polyoxypropylene ether polyol: 40g, glycerol: 6g, triethylenediamine: 0.3g, water: 0.3g, polyether modified polysiloxane: 0.4g, dimethoxyphthalate Ethylene glycol ester: 6g, stirred evenly to prepare material A.

[0020] Under the protection of nitrogen, heat and melt pure MDI, add dehydrated polyoxypropylene ether polyol, react at 70-80°C for 2-3 hours, remove air bubbles in a vacuum, and naturally cool down to obtain a preform with -NCO as the end group. Polymer. The weight fraction of terminal group-NCO in the prepolymer is 16%-25%.

[0021] Take the prepolymer: 40g, which is material B.

[0022] Take graphite: 2g, aluminum borate whiskers: 5g, mix evenly, and perform surface pretreatment with coupling agent to obtain material C. Described coupling agent surface pretreatment ...

Embodiment 2

[0030] The adipate polyester polyol is dehydrated. The specific operation method is: place the adipate polyester polyol in a vacuum oven at 95-105°C and dry for 2-4 hours.

[0031] Get the adipic acid polyester polyol after dehydration treatment: 42g, 1,4-butanediol: 5g, triethylamine: 0.3g, water: 0.3g, polydimethylsiloxane: 0.4g, phthalic acid Dipropylene glycol ester: 4g, stirred evenly to prepare material A.

[0032] Under the protection of nitrogen, heat and melt pure MDI, add dehydrated adipic acid polyester polyol, react at 70-80°C for 2-3 hours, remove air bubbles in a vacuum, and naturally cool down to obtain -NCO prepolymer. The weight fraction of terminal group-NCO in the prepolymer is 16%-25%.

[0033] Take the prepolymer: 42g, which is material B.

[0034] Take graphite: 2g, aluminum borate whisker: 4g, mix evenly, and perform surface pretreatment with coupling agent to obtain material C. Described coupling agent surface pretreatment method is as follows:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistance | aaaaa | aaaaa |

| Volume resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com