Zirconia-doped alumina ceramic and preparation method thereof

A technology of alumina ceramics and zirconia, applied in the field of alumina ceramics doped with zirconia and its preparation, to achieve the effects of increasing density, increasing densification, and improving production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

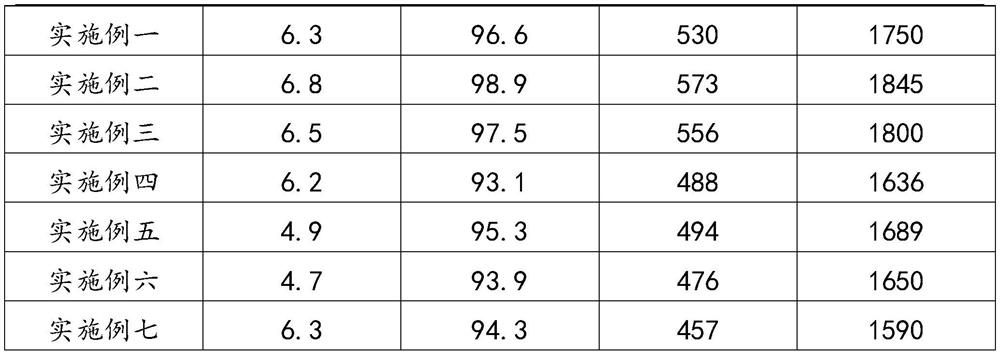

Examples

Embodiment 1

[0036]A zirconia-doped alumina ceramic, which is made of the following raw materials in parts by weight: 75 parts of α-alumina, 5 parts of yttria-stabilized zirconia, 2 parts of aluminum borate whiskers, titanium dioxide 2.4 parts, 3.6 parts of alkali-free aluminosilicate glass, 0.8 part of sodium polyacrylate, 2.1 parts of polyvinyl alcohol, 18 parts of isopropanol, 1.5 parts of dimethyl phthalate, and the alkali-free aluminosilicate glass consists of the following mass percentages The raw material composition: 20wt.% alumina, 56wt.% silicon dioxide, 24wt.% zinc oxide.

[0037] A method for preparing alumina ceramics doped with zirconia, comprising the following steps:

[0038] (1) Take each raw material according to the formula ratio, and set aside;

[0039] (2) The coupling agent and ethanol are formulated into a solution at a mass ratio of 1:20, and the yttria-stabilized zirconia is added to the solution, and the mass ratio of the yttria-stabilized zirconia to the couplin...

Embodiment 2

[0046] A zirconia-doped alumina ceramic, which is made of the following raw materials in parts by weight: 85 parts of α-alumina, 10 parts of yttria-stabilized zirconia, 4 parts of aluminum borate whiskers, titanium dioxide 5 parts, 4 parts of alkali-free aluminosilicate glass, 1.5 parts of naphthenic oil, 5 parts of polyvinyl butyral, 27 parts of butyl acetate, 4 parts of diethyl phthalate, the alkali-free aluminosilicate glass is composed of The following raw material composition by mass percentage: 22wt.% alumina, 60wt.% silicon dioxide, 18wt.% zinc oxide.

[0047] A method for preparing alumina ceramics doped with zirconia, comprising the following steps:

[0048] (1) Take each raw material according to the formula ratio, and set aside;

[0049] (2) The coupling agent and ethanol are formulated into a solution at a mass ratio of 1:20, and the yttria-stabilized zirconia is added to the solution, and the mass ratio of the yttria-stabilized zirconia to the coupling agent is 8...

Embodiment 3

[0056] A zirconia-doped alumina ceramic, which is made of the following raw materials in parts by weight: 95 parts of α-alumina, 15 parts of yttria-stabilized zirconia, 6 parts of aluminum borate whiskers, titanium dioxide 4 parts, 8 parts of alkali-free aluminosilicate glass, 2 parts of polyethylene glycol, 8.4 parts of carboxypropyl methylcellulose, 36 parts of ethanol, 6 parts of trioctyl phosphate, the alkali-free aluminosilicate glass consists of the following mass percentages The raw material composition: 25wt.% alumina, 64wt.% silicon dioxide, 11wt.% zinc oxide.

[0057] A method for preparing alumina ceramics doped with zirconia, comprising the following steps:

[0058] (1) Take each raw material according to the formula ratio, and set aside;

[0059] (2) The coupling agent and ethanol are formulated into a solution in a mass ratio of 1:20, and the yttria-stabilized zirconia is added to the solution, and the mass ratio of the yttria-stabilized zirconia to the coupling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com