Rock plate with mutton fat jade touch feeling and preparation method thereof

A suet and tactile technology, applied in the field of slate with suet jade touch and its preparation, can solve the problems of many glass phases and insufficient wear resistance, and achieve good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

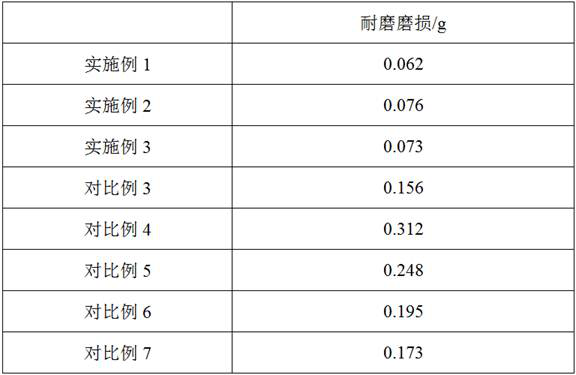

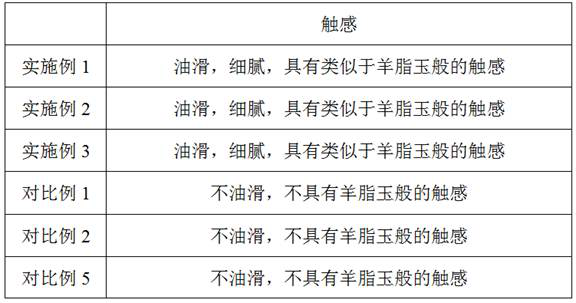

Examples

Embodiment 1

[0032] A rock slab with suet jade tactility comprises a body layer and a glaze layer from bottom to top, and the glaze layer is formed by applying suet jade glaze on the body layer and sintering.

[0033] The suet jade glaze is prepared from the following raw materials in parts by weight: 33 parts of potassium-containing minerals, 26 parts of kaolin, 16 parts of quartz sand, 10 parts of modified aluminum borate whiskers, 7 parts of spodumene, and 6 parts of lubricant , 2 parts of calcium silicate.

[0034] Under the formula system with potassium-containing minerals and kaolin as main ingredients, by adding a lubricant, a rock slab with a smooth and delicate touch and a touch similar to suet jade can be obtained.

[0035] The potassium-containing mineral is composed of illite, potassium feldspar and muscovite in a weight ratio of 5:3:2.

[0036] The use of the above-mentioned potassium-containing minerals can improve the wear resistance to a certain extent, and can significant...

Embodiment 2

[0049] A rock slab with suet jade tactility comprises a body layer and a glaze layer from bottom to top, and the glaze layer is formed by applying suet jade glaze on the body layer and sintering.

[0050] The suet jade glaze is prepared from the following raw materials in parts by weight: 34 parts of potassium-containing minerals, 28 parts of kaolin, 20 parts of quartz sand, 6 parts of modified aluminum borate whiskers, 8 parts of spodumene, and 3 parts of lubricant , 1 part calcium silicate.

[0051] The potassium-containing mineral is composed of illite, potassium feldspar and muscovite in a weight ratio of 2:2:1.

[0052] The preparation method of described modified aluminum borate whisker is:

[0053] S1. Add 3 parts by weight of sodium oxalate, 2 parts by weight of sodium lignosulfonate, and 4 parts by weight of glycerin to 30.8 parts by weight of deionized water to prepare a mixed solution, and then add 10 parts by weight of aluminum borate whiskers to the mixed solutio...

Embodiment 3

[0062] A rock slab with suet jade tactility comprises a body layer and a glaze layer from bottom to top, and the glaze layer is formed by applying suet jade glaze on the body layer and sintering.

[0063] The suet jade glaze is prepared from the following raw materials in parts by weight: 31 parts of potassium-containing minerals, 30 parts of kaolin, 15 parts of quartz sand, 9 parts of modified aluminum borate whiskers, 6 parts of spodumene, and 5 parts of lubricant , 4 parts of calcium silicate.

[0064] The potassium-containing minerals are composed of illite, potassium feldspar and muscovite in a weight ratio of 6:3:1.

[0065] The preparation method of described modified aluminum borate whisker is:

[0066] S1. Add 2 parts by weight of sodium oxalate, 1.5 parts by weight of sodium lignosulfonate, and 2.5 parts by weight of glycerin to 33.7 parts by weight of deionized water to prepare a mixed solution, and then add 10 parts by weight of aluminum borate whiskers to the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com