3A-grade natural antibacterial anti-mite kapok fabric and preparation method thereof

A natural antibacterial and kapok technology, applied in the field of textile and clothing, can solve the problems of easy static electricity, sticky wearing, heavy and bloated, etc., and achieve the effect of not easy to generate static electricity and delicate touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of the above-mentioned 3A grade natural antibacterial and anti-mite kapok fabric comprises the following steps:

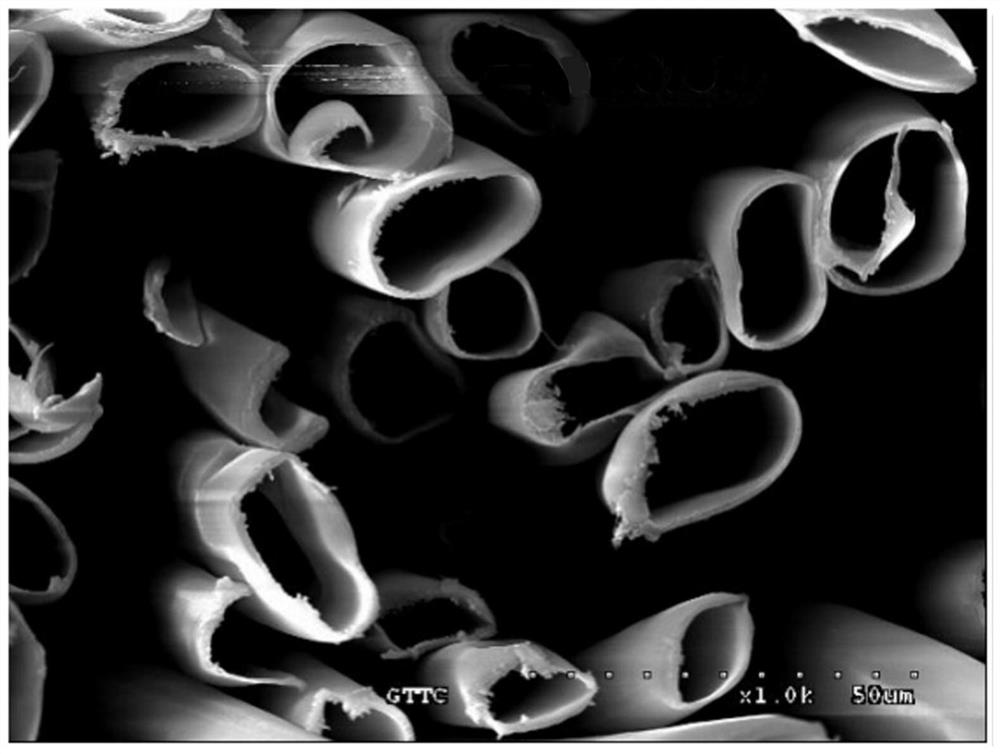

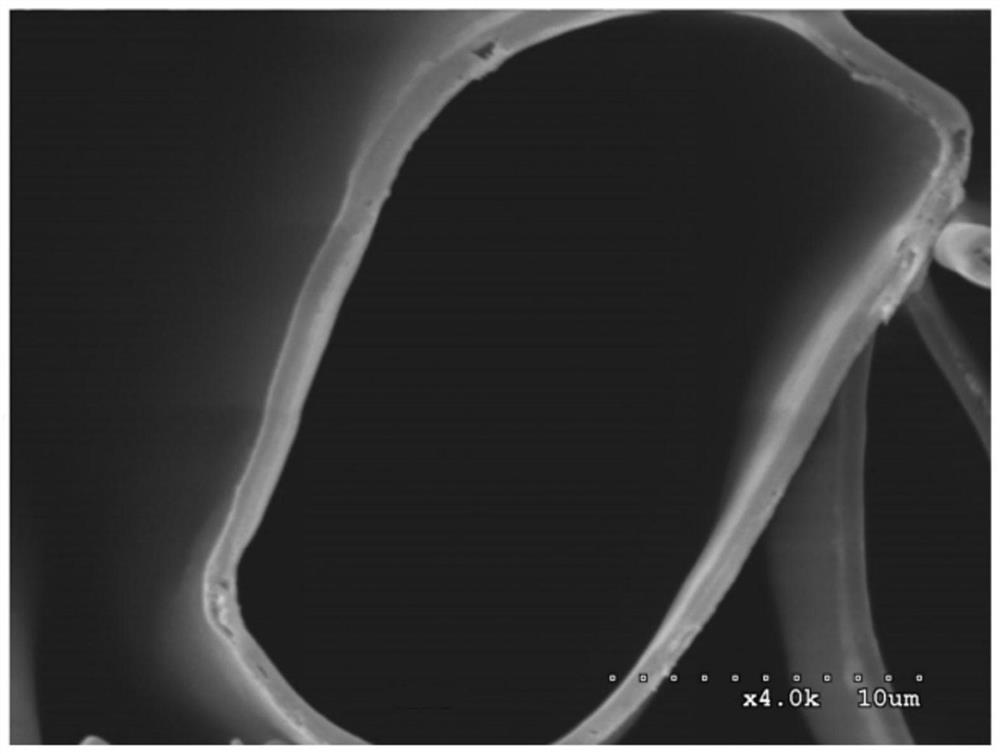

[0053] The first step is to use the kapok pretreatment auxiliary to pretreat the natural kapok fiber to improve its spinning performance. Because kapok fibers are short, easy to float, strong in rigidity and poor in cohesion, pretreatment is required before spinning.

[0054] Preferably, the kapok pretreatment agent is selected from the SP-KAPOK 21AW auxiliary agent provided by Su Pai Technology (Shanghai) Co., Ltd.

[0055] In step 2, the kapok fiber pretreated in step 1 is mixed with the main fiber and the elastic fiber and opened, and then carded, drawn and spun to obtain kapok blended yarn. Kapok blended yarn is 7-60s air-spun, ring-spun or siro-spun yarn.

[0056] Step 3: knitting the kapok blended yarn into jersey or gray cloth of jacquard fabric by using circular knitting machine, single-sided or double-sided jacquard machine....

Embodiment 1

[0063] The production process of kapok fabric is as follows:

[0064] The kapok fibers are pretreated, then mixed with cotton fibers and opened, then carded, drawn and spun to obtain 32s cotton / kapok ring spinning. In this kind of 32s cotton / kapok ring spinning, the composition and mass percentage of fiber raw materials are: 70% of cotton fiber and 30% of kapok fiber.

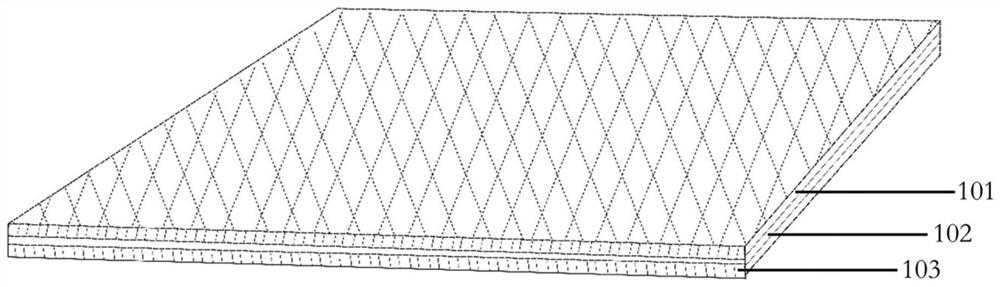

[0065] The prepared 32s cotton / kapok ring spinning is used as the veil of the upper and lower layers on the knitting jacquard machine, and a bunch of nylon pre-oriented shrinkage yarns are placed in the middle to obtain the thermal underwear gray fabric with the wires in the middle, such as image 3 shown. The upper layer and the lower layer are respectively 32s cotton / kapok veil 101 and 32s cotton / kapok veil 103, and the middle layer 102 of nylon pre-oriented yarn is between them.

[0066] Gray fabric dyeing and finishing process route: pretreatment of desizing and scouring - low temperature activated bleach...

Embodiment 2

[0068] The production process of kapok fabric is as follows:

[0069] The kapok fibers are pretreated, then mixed with cotton fibers and opened, then carded, drawn and spun to obtain 40s cotton / kapok ring spinning. In such 40s cotton / kapok ring spinning, the composition and mass percentage of fiber raw materials are: 80% cotton fiber and 20% kapok fiber.

[0070] Spin the prepared 40s cotton / kapok ring spinning on the double-sided jacquard machine as the veil of the upper and lower layers, and feed 3% spandex elastic fiber at the same time to obtain the thermal underwear gray fabric with the special texture of the AB surface and the air layer in the middle, such as Figure 4 shown. The upper layer and the lower layer are 40s cotton / kapok veil 201 and 40s cotton / kapok veil 203 respectively, and the middle air layer 202 is between them.

[0071] According to calculation, the fiber components and mass percentages in the gray cloth are about 77.67% of cotton fiber, 19.42% of kap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com