Patents

Literature

32results about How to "Not easy to static electricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

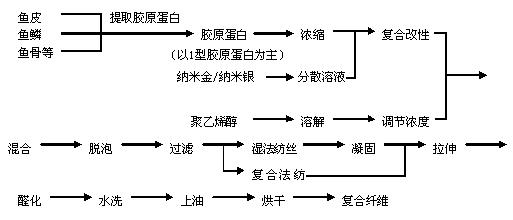

Fish collagen composite fibers and preparation method thereof

InactiveCN102181959AImprove toughness and strengthOvercome instabilityConjugated cellulose/protein artificial filamentsWet spinning methodsPolyvinyl alcoholFiber

The invention discloses fish collagen composite fibers and a preparation method thereof. The fish collagen composite fibers comprise the following components in parts by weight: 100 parts of fish collagen, 0.01-10 parts of nano gold sol and / or nano silver sol and 100-800 parts of polyvinyl alcohol. The method comprises the following steps: (1) extracting and separating fish collagen; (2) enabling the fish collagen and nano gold and / or nano silver to carry out a composite copolymerization and cross-linking reaction according to the proportion; (3) mixing a modified fish collagen solution with a polyvinyl alcohol solution and stirring the mixed solution; and (4) carrying out spinning, drawing and hydroformylation after carrying out deaeration and filtration on the spinning solution of the fish collagen composite fibers to obtain the fish collagen composite fibers. The fish collagen composite fibers and the preparation method have the following effects: the flexibility of the composite fibers can be improved; and the strength and elongation of the collagen composite fibers can be substantially improved.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Environment-friendly flame-retardant rubber floor and manufacturing method thereof

InactiveCN107090106AImprove wear resistanceUniform colorCovering/liningsFlat articlesStearic acidAccelerant

The invention discloses environment-friendly flame-retardant rubber floor. The environment-friendly flame-retardant rubber floor is prepared from the following raw materials in parts by weight: 20-30 parts of butadiene styrene rubber, 50-60 parts of acrylonitrile-butadiene rubber, 6-8 parts of titanium dioxide, 4-6 parts of a vulcanizing agent, 1-3 parts of zinc oxide, 0.5-2 parts of stearic acid, 4-6 parts of white carbon black, 0.8-1.4 parts of an accelerant, 1-2 parts of a weather resistant, 3-5 parts of antimonous oxide, 5-7 parts of a flame retardant, 1-3 parts of an antistatic agent and 20-30 parts of reinforcing filler. The rubber floor disclosed by the invention has the advantages of stronger wear resistance, static electricity resistance, low smoke, low toxicity, low corrosion, good flame resistance, high tensile strength, good skid resistance, good resilience and the like. A manufacturing method for the rubber floor adopts safe and reliable raw material components, is harmless on environment, adopts easily available raw materials, is relatively low in cost, is simple in process, is easy to operate and realize industrial production, and has relatively high practical value and a good application prospect.

Owner:合肥市老海新材料有限公司

Antibacterial and anti-mite blended non-woven fabric based on polylactic acid fibers

InactiveCN110791879ASolve the lack of natural antibacterial and anti-mite effectsGood biocompatibilityNon-woven fabricsUndergarmentsEngineeringNonwoven fabric

The invention discloses an antibacterial and anti-mite blended non-woven fabric based on polylactic acid fibers. The blended non-woven fabric is prepared by mixing the polylactic acid fibers with absorbent cotton. The specific preparation process comprises the following steps: preparing raw materials; feeding the the raw materials into a disc plucker; feeding the raw materials into a multi-bin cotton mixer; feeding the raw materials into a finishing machine; feeding the raw materials into a carding machine; feeding the raw materials into a cross lapping machine; feeding the raw materials intoa fiber drafting machine; carrying out spunlace treatment; feeding the raw materials into a coiling machine; carrying out drying treatment; feeding the raw materials into a splitting machine; and packaging and warehousing. The problem that an existing all-cotton spunlaced non-woven fabric does not have natural antibacterial and anti-mite effects is solved, and after a certain proportion of polylactic acid fibers are blended in all-cotton, the natural antibacterial and anti-mite characteristics of the polylactic acid fibers are utilized, so that the blended non-woven fabric also has the naturalantibacterial and anti-mite functions.

Owner:安庆市嘉欣医疗用品科技股份有限公司

Waterproof building external wall coating

InactiveCN110358420AImprove waterproof performanceEnhance water resistance and crack resistanceAntifouling/underwater paintsPaints with biocidesKaolin clayMaterials science

The invention discloses a waterproof building external wall coating. The waterproof building external wall coatingis prepared from the following components in parts by weight: pure acrylic emulsion, methacrylic acid emulsion, alkyd resin, silica sol, defoamer, titanium dioxide nanometer powder, 2-hydroxyl-4-n-octyloxy-benzophenone, cyclohexanone-oxime, modified kaolin clay, titanium dioxide, sepiolite, methylsilicone oil, methyl alkoxy silicone oil, octyltriethoxysilane, silane quaternary ammonium salt, surfactants, and mildew preventive. According to the waterproof external wall coating, a waterproof agent with good waterproof performance is introduced, so that the external wall coatingishigh in waterproof performance.

Owner:曾敏偲

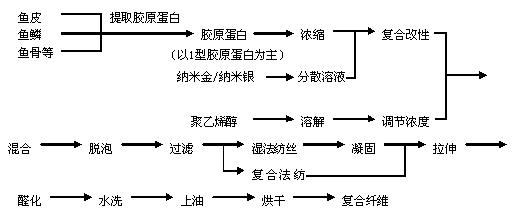

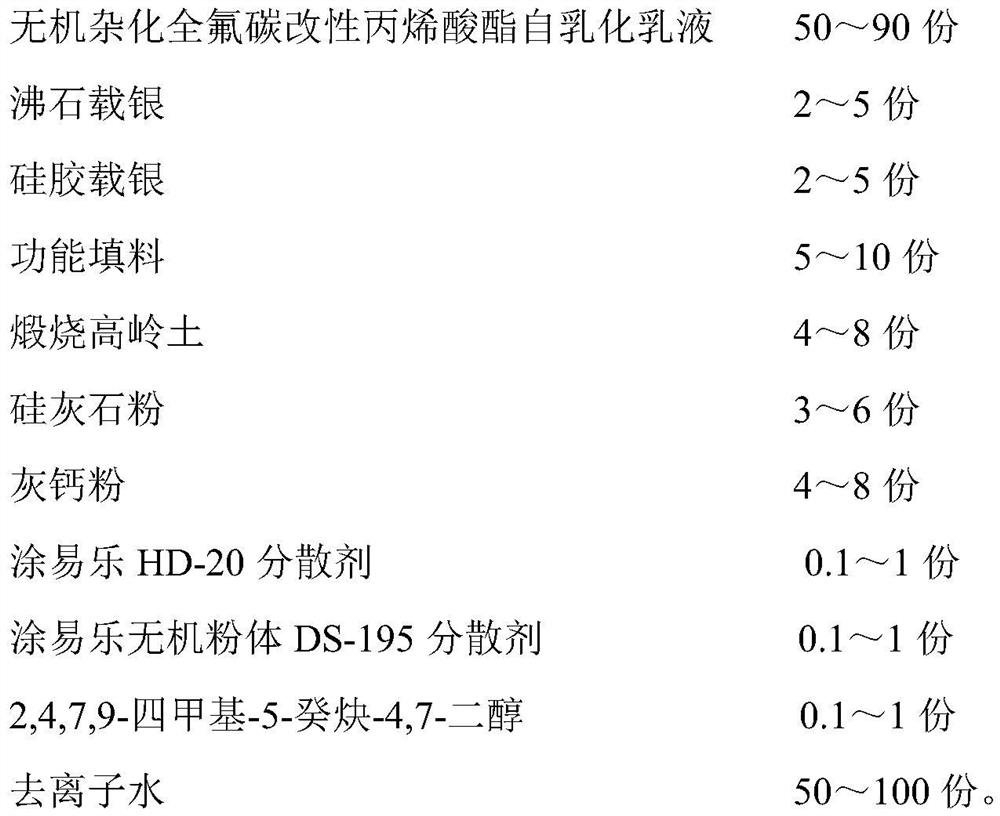

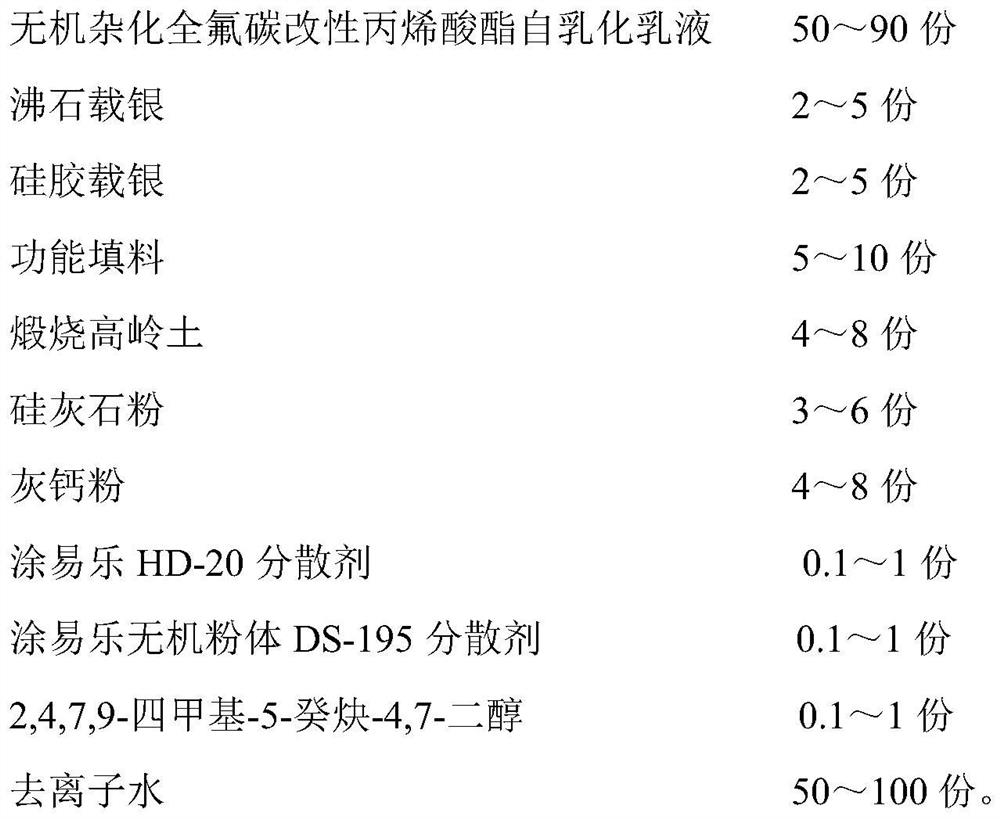

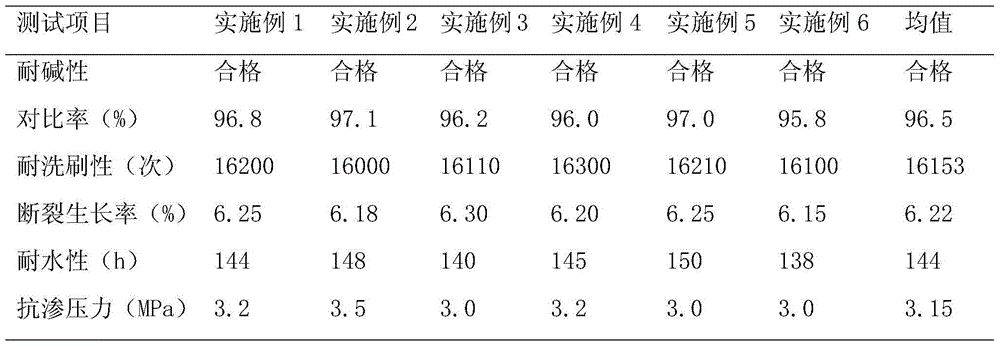

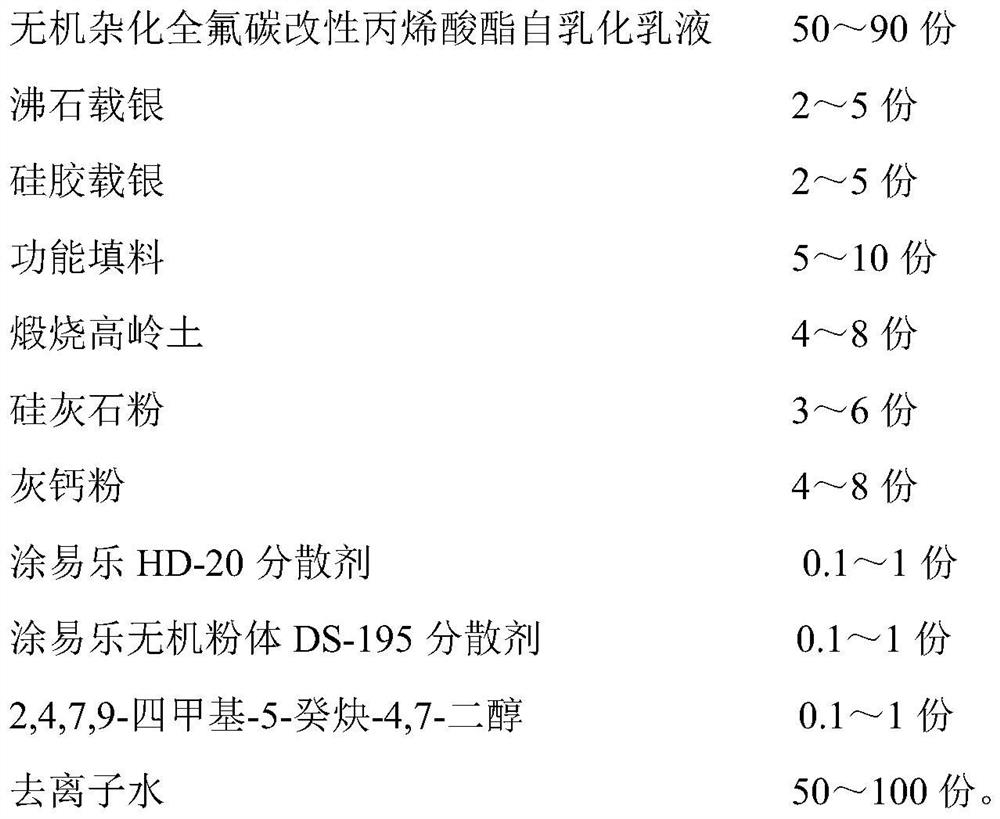

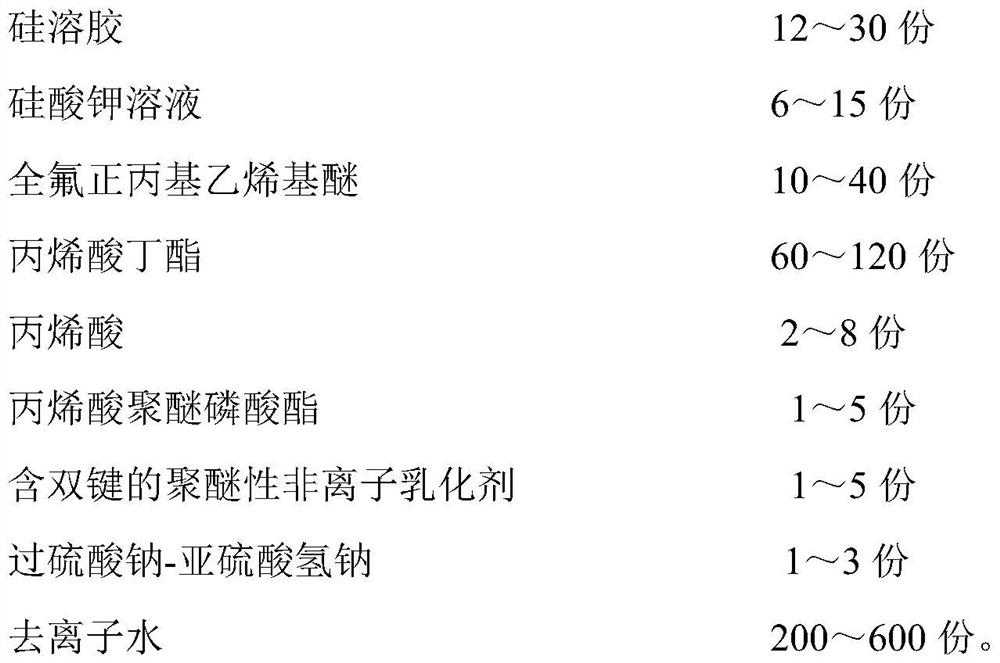

Organic-inorganic antibacterial antifouling interior wall coating and preparation method thereof

ActiveCN112920667AChemically resistantFlame retardantFireproof paintsAntifouling/underwater paintsMeth-Kaolin clay

The invention relates to the technical field of coatings, in particular to an organic-inorganic antibacterial antifouling interior wall coating and a preparation method thereof. The coating is prepared from an inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion, zeolite-loaded silver, silica gel-loaded silver, a functional filler, calcined kaolin, wollastonite powder, ash calcium powder, a Taieasy HD-20 dispersing agent, a Taieasy inorganic powder DS-195 dispersing agent, 2, 4, 7, 9-tetramethyl-5-decyne-4, 7-diol and deionized water. The inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion is used as a base material, and zeolite-loaded silver and silica gel-loaded silver are used as a composite inorganic mildew preventive, so that the coating has the characteristics of chemical corrosion resistance, flame retardance, fire prevention and environmental protection of an inorganic coating and the advantages of strong adhesive force and good scrubbing resistance of an organic coating; the coating is safe and non-toxic, excellent in mildew-proof performance and long in mildew-proof validity period.

Owner:ZIBO VOCATIONAL INST

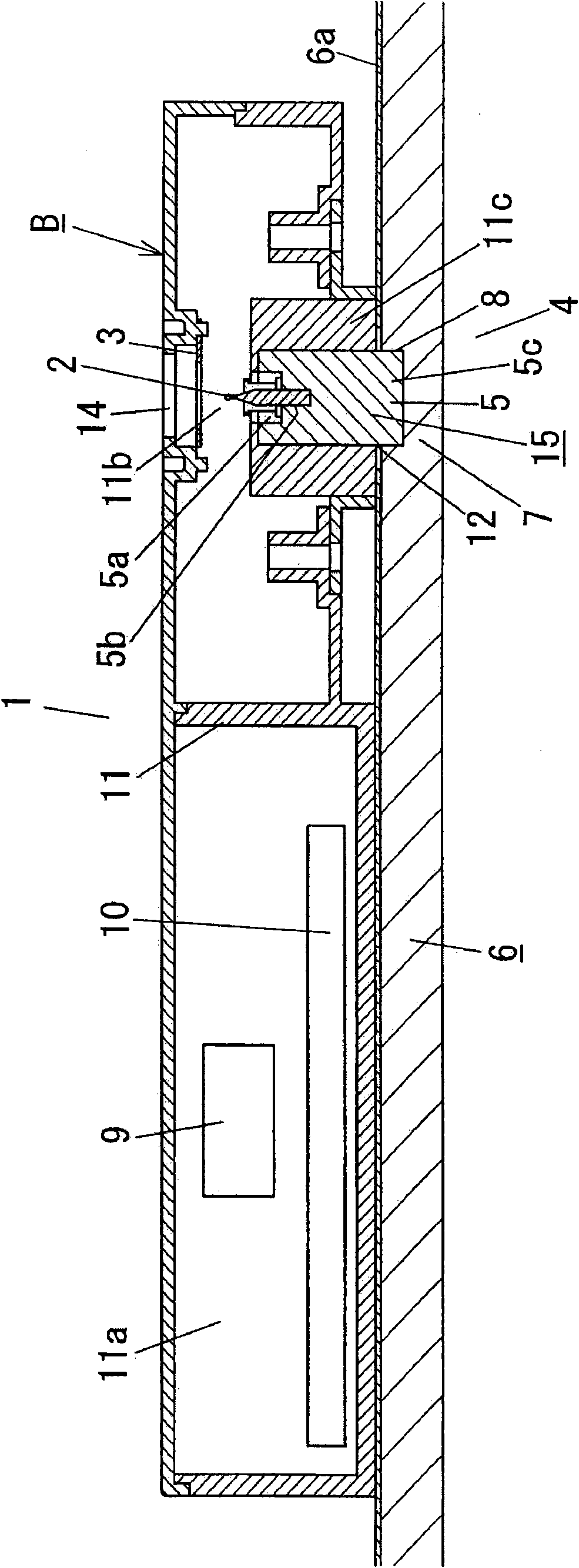

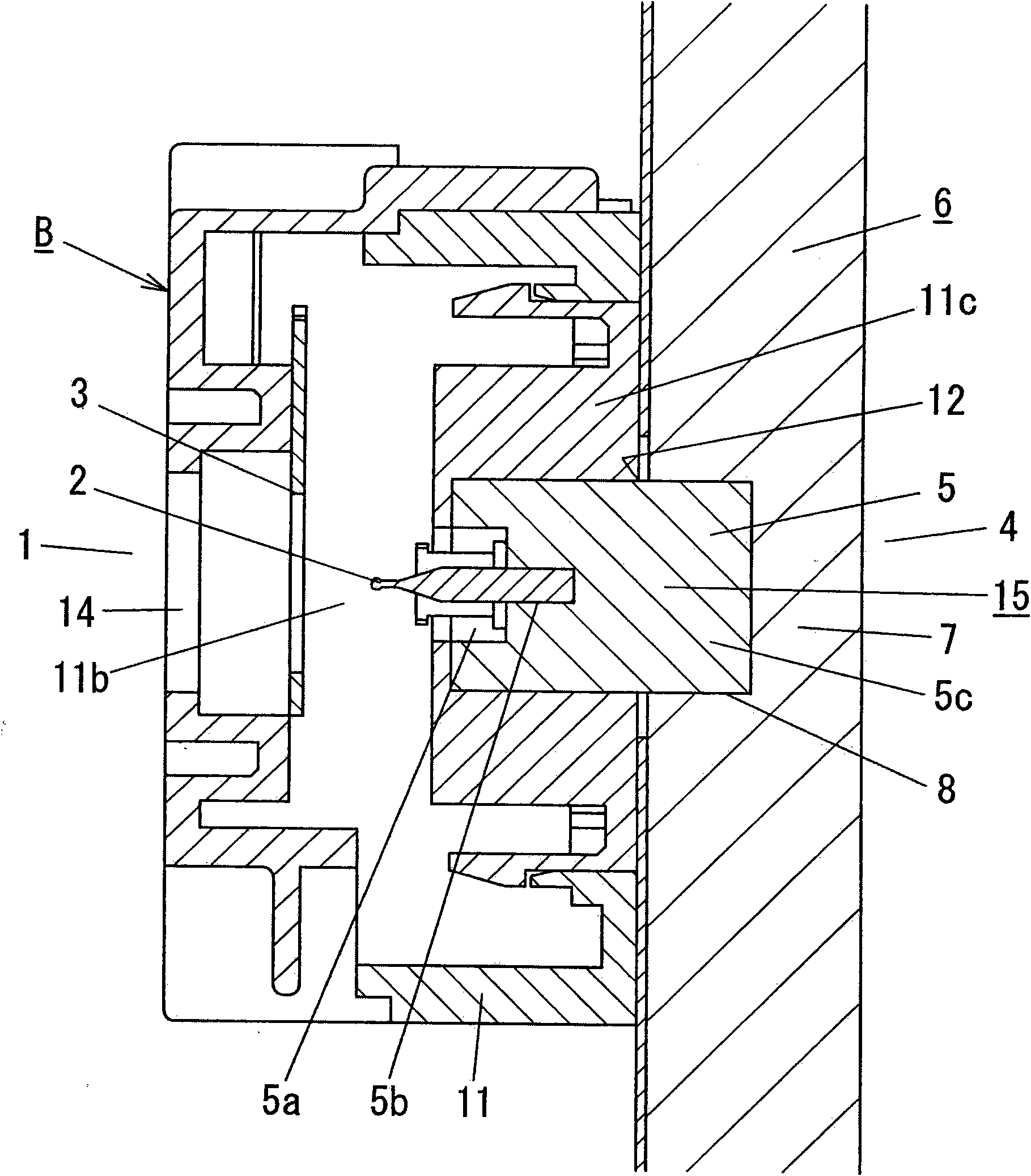

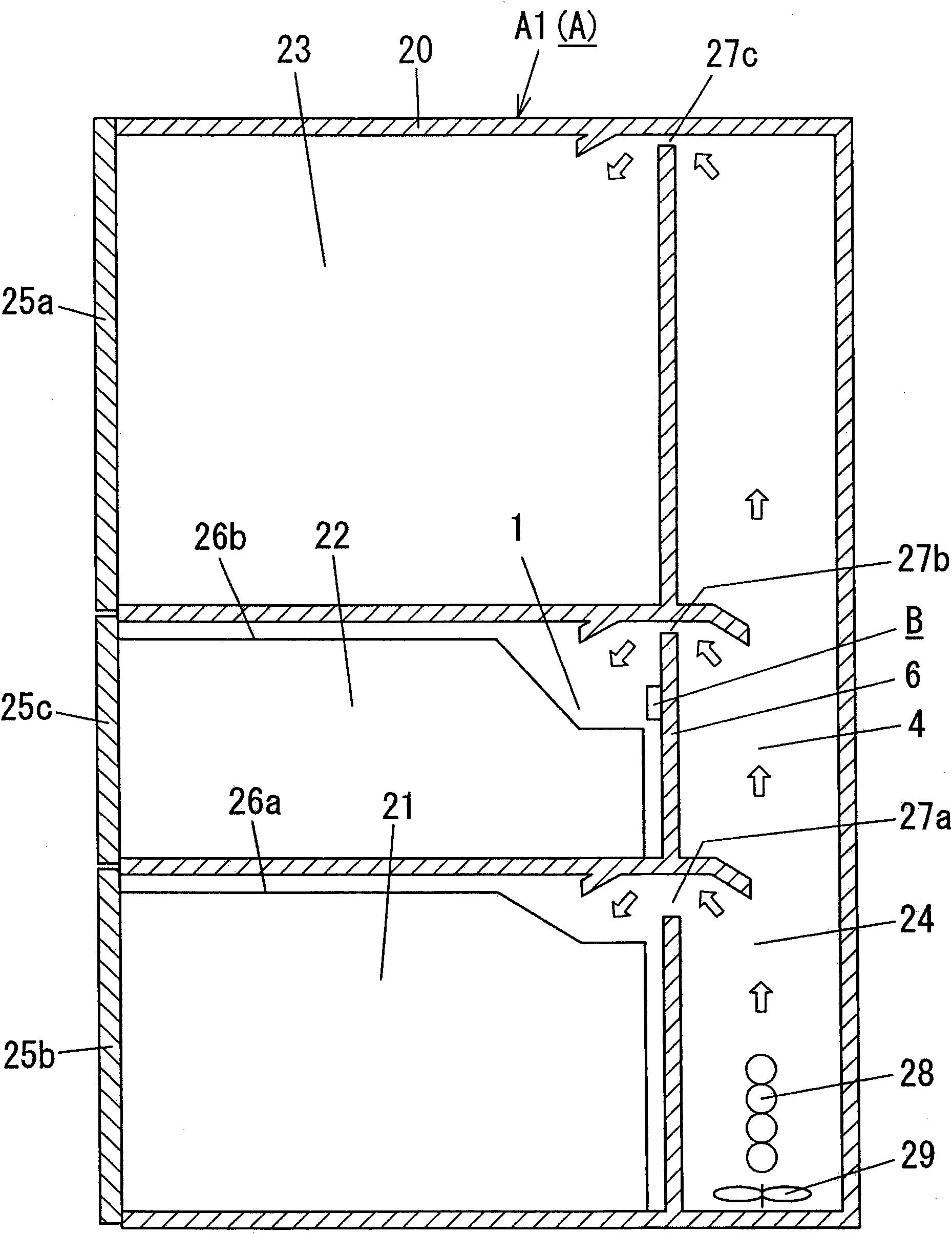

Electrostatic atomizer

ActiveCN101557880ANot easy to static electricityLighting and heating apparatusElectrostatic spraying apparatusEngineeringHigh voltage

Disclosed is an electrostatic atomizer, which comprises a high-voltage applying section 9 adapted to apply a high voltage between an atomizing electrode 2 and a counter electrode 3 so as to electrostatically atomize water supplied onto the atomizing electrode 3, wherein the high-voltage applying section 9 is operable to set an absolute value of a voltage to be applied to the atomizing electrode smaller than an absolute value of a voltage to be applied to the counter electrode 3. This allows a physical object, such as an article stored in a mist-receiving space or an inner wall of a structural member defining the mist-receiving space to become less likely to be electrostatically charged, and makes it possible to avoid causing a problem about discomfort due to discharge of static charges when a user touches the physical object.

Owner:PANASONIC ELECTRIC WORKS CO LTD

Environment-friendly, antistatic and wear-resistant plastic track material and preparation method thereof

The invention discloses an environment-friendly, antistatic and wear-resistant plastic track material and a preparation method thereof. The environment-friendly, antistatic and wear-resistant plastictrack material comprises the following raw materials in parts by weight: 40 to 50 parts of a waste plastic raw material, 25 to 35 parts of polyether polyol, 20 to 30 parts of PE resin, 15 to 25 partsof a maleic anhydride-styrene copolymer, 7 to 11 parts of a reinforcement filling material, 8 to 14 parts of a modified adhesion auxiliary agent, 7 to 9 parts of a compound flame retardant, 6 to 8 parts of a modified nanometer additive, 3 to 5 parts of a coupling agent, 1 to 2 parts of an antistatic agent, 10 to 12 parts of a processing auxiliary agent and 3 to 5 parts of electroconductive carbonblack. The material provided by the invention has the characteristics of uniform dispersion, good mechanical properties, excellent antistatic performance, good thermal conductivity, strong flame retardancy, wear resistance and weather resistance, excellent toughness and strength, etc.; meanwhile, the preparation method provided by the invention has the advantages of safe and reliable raw materialcomponents, low cost, simple and clear process, easiness in operation and implementation of industrial production, high practical value, and good application prospect.

Owner:合肥佳洋电子科技有限公司

Preparation process for diatom mud formaldehyde-removing indoor coating

The invention relates to a preparation process for a diatom mud formaldehyde-removing indoor coating. The coating mainly comprises the following components in percentages by mass: 15-35% of diatomaceous earth, 0.2-1% of a dispersant, 0.1-2% of a surfactant, 15-25% of modified starch, 10-17% of a synthetic emulsion, 6-13% of nano-sized titanium dioxide, 5-12% of talc powder, 0-30% of a filler, 0.5-2% of a silver ion antibacterial agent, 1-5% of an auxiliary agent, 0.3-0.5% of a wetting agent, 0.2-0.5% of a defoaming agent, 10-15% of activated carbon, and the balance of water. In a word, the coating provided by the invention has the advantages of a wide range of raw material sources, low price, safety, environmental protection, and strong formaldehyde-adsorbing ability.

Owner:德马科起重机械有限公司

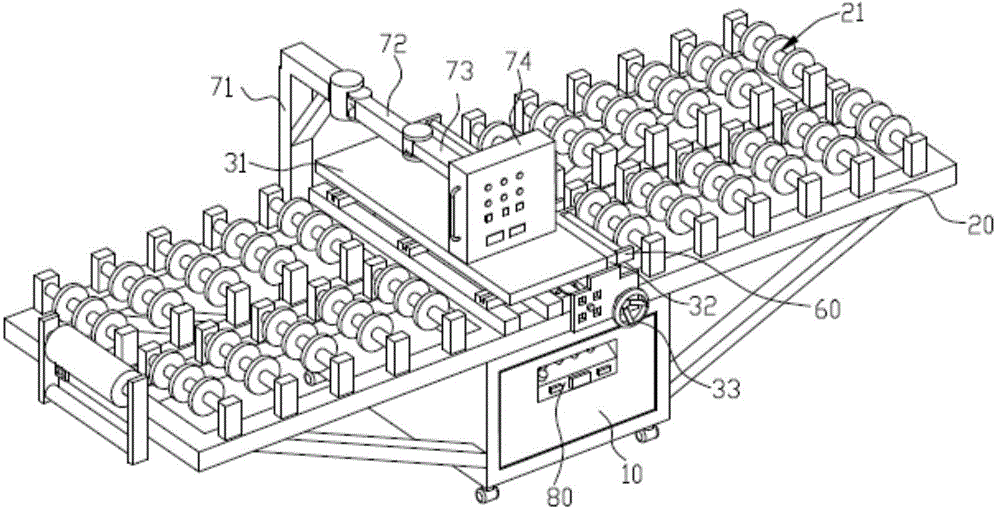

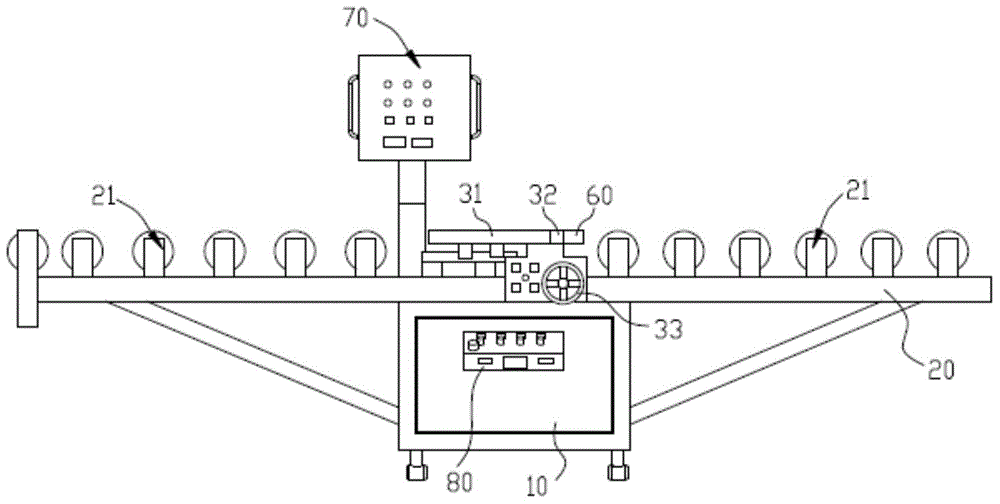

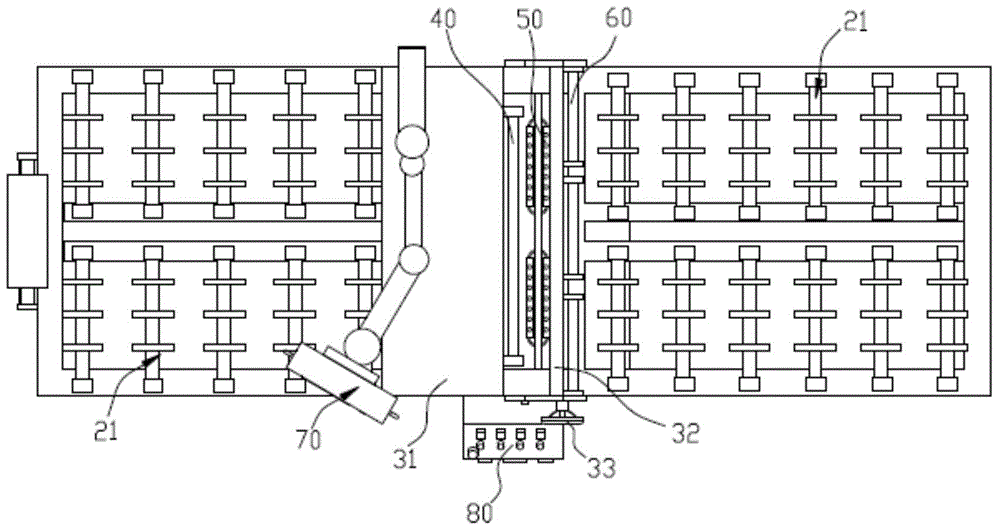

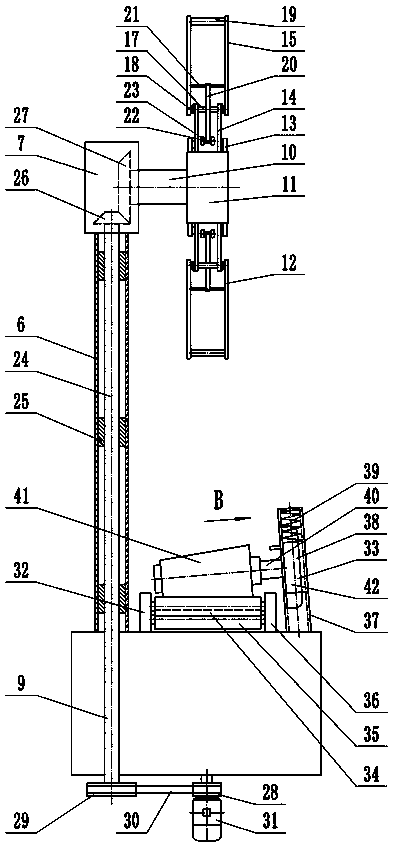

Polaroid stripping machine

InactiveCN104875472ANot easy to deform and damageReduce damage and deformationLamination ancillary operationsLaminationBiochemical engineering

The invention discloses a polaroid stripping machine which comprises a base cabinet, a support frame, a workbench unit, a rotating shaft unit, a heating device, a destaticizing device, a first control cabinet unit and a second control cabinet. The support frame is fixedly arranged on the base cabinet. The workbench unit is arranged on the support frame. The rotating shaft unit is fixedly disposed on the top of the base cabinet and positioned below the workbench unit. The heating device is fixedly arranged on the top of the base cabinet and positioned at one side of the rotating shaft unit. The destaticizing device is fixedly arranged at one side of the workbench unit. The first control cabinet unit is mounted on the base cabinet. The second control cabinet is movably arranged on the base cabinet. The polaroid stripping machine has advantages of good polaroid stripping effect and high work efficiency.

Owner:佑仁电子科技(苏州)有限公司

High-strength polyester cotton yarn

Provided is a high-strength polyester cotton yarn. The invention includes two parts of ingredients and technological process. Through adding various kinds of different fibers in a textile process, hygroscopicity and gas permeability of the polyester cotton are improved, and through adding an antistatic agent, the polyester cotton does not easily generate static electricity.

Owner:安徽创星实业有限公司

Inorganic waterproof anticorrosive coating and preparation method thereof

ActiveCN104592793AStrong adhesionGood chemical resistanceAntifouling/underwater paintsPaints with biocidesEmulsionCalcium

The invention discloses an inorganic waterproof anticorrosive coating and a preparation method thereof. The coating is composed of the following raw materials: silicon sol, calcium sulphate whisker, a pigment, a filling agent, an ethylene-propylene emulsion, propylene glycol, a pH regulator, a dispersing agent, a film-forming aid, a defoaming agent, a thickening agent and water. The preparation method comprises the following steps: weighing all the raw materials in proportion, and dividing the defoaming agent into a part A and a part B which are equal in weight; adding water in a container, adding the silicon sol, the dispersing agent, the part A of the defoaming agent, the propylene glycol and the pH regulator at a low rotating speed, and uniformly dispersing; adding the pigment, the filling agent and the calcium sulphate whisker at an increased rotating speed, and dispersing the materials until the grain fineness is less than 50mu m; sequentially adding the part B of the defoaming agent, the film-forming aid, the ethylene-propylene emulsion and the thickening agent at a reduced rotating speed, and uniformly dispersing. The coating disclosed by the invention has excellent waterproof, anti-corrosion and anti-seepage properties, and is non-toxic and environmental-friendly; and the preparation method is simple in operation, convenient to produce, low in requirements on equipment, and suitable for industrial mass production.

Owner:厦门友连科技有限公司

Manufacturing technology of anti-static anti-radiation electric-conductive cloth

InactiveCN104651886APrevent volatilizationPlay the role of radiation protectionConductive layers on insulating-supportsElectrolytic coatingsFiberPolyester

The invention provides a manufacturing technology of an anti-static anti-radiation electric-conductive cloth and especially provides the manufacturing technology of the anti-static anti-radiation electric-conductive cloth used in automatic control equipment. The manufacturing technology includes following steps: (1) preparing 100 g of graphene, 18 g of metal nickel, a proper amount of an anti-oxidizing agent and a piece of a polyester fiber electric-conductive cloth; (2) electroplating the metal nickel and electroplating the graphene onto the metal nickel, wherein the graphene is high in electric-conductivity; (3) after immobilization, electroplating the anti-oxidizing agent onto the graphene and performing mixing with the polyester fiber electric-conductive cloth; and (4) performing physical volatilization at a normal temperature of 3-7 DEG C for 5-15 min to prepare the electric-conductive cloth. The invention is characterized in that harmful substances in the equipment are effectively prevented from volatilizing so that a certain anti-radiation effect is achieved. The electric-conductive cloth is not liable to generate static electricity, is breathable and soft, is good in comfort, is free of external interference when being used in the automatic control equipment, can prolong the service life of the equipment and is quite convenient to use.

Owner:QINGDAO GUYU GRAPHITE

Antistatic water-based adhesive for vulcanized shoes and preparation method thereof

InactiveCN111253865AFast curing rateAccelerated curing moldingNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseFiber

The invention discloses an antistatic water-based adhesive for vulcanized shoes and a preparation method of the antistatic water-based adhesive. The antistatic water-based adhesive for vulcanized shoes is prepared from a water-based polyurethane dispersion, dicyanoisobutyl acrylate, cassava starch, soybean fibers, polyethylene glycol, diaminodiphenyl methane, vinyltriamine, aluminum sulfate, an antistatic agent, sodium carboxymethyl cellulose and deionized water. The prepared antistatic water-based adhesive for vulcanized shoes is high in curing rate, can be quickly cured and formed in the vulcanized shoes, is smooth in surface and does not easily generate static electricity. The antistatic agent is added, so that the antistatic performance of the antistatic water-based adhesive is furtherenhanced, and the static electricity is not easily generated. The wearing comfort and safety can be obviously improved, and the application field is expanded.

Owner:泉州市泉石通智能科技有限公司

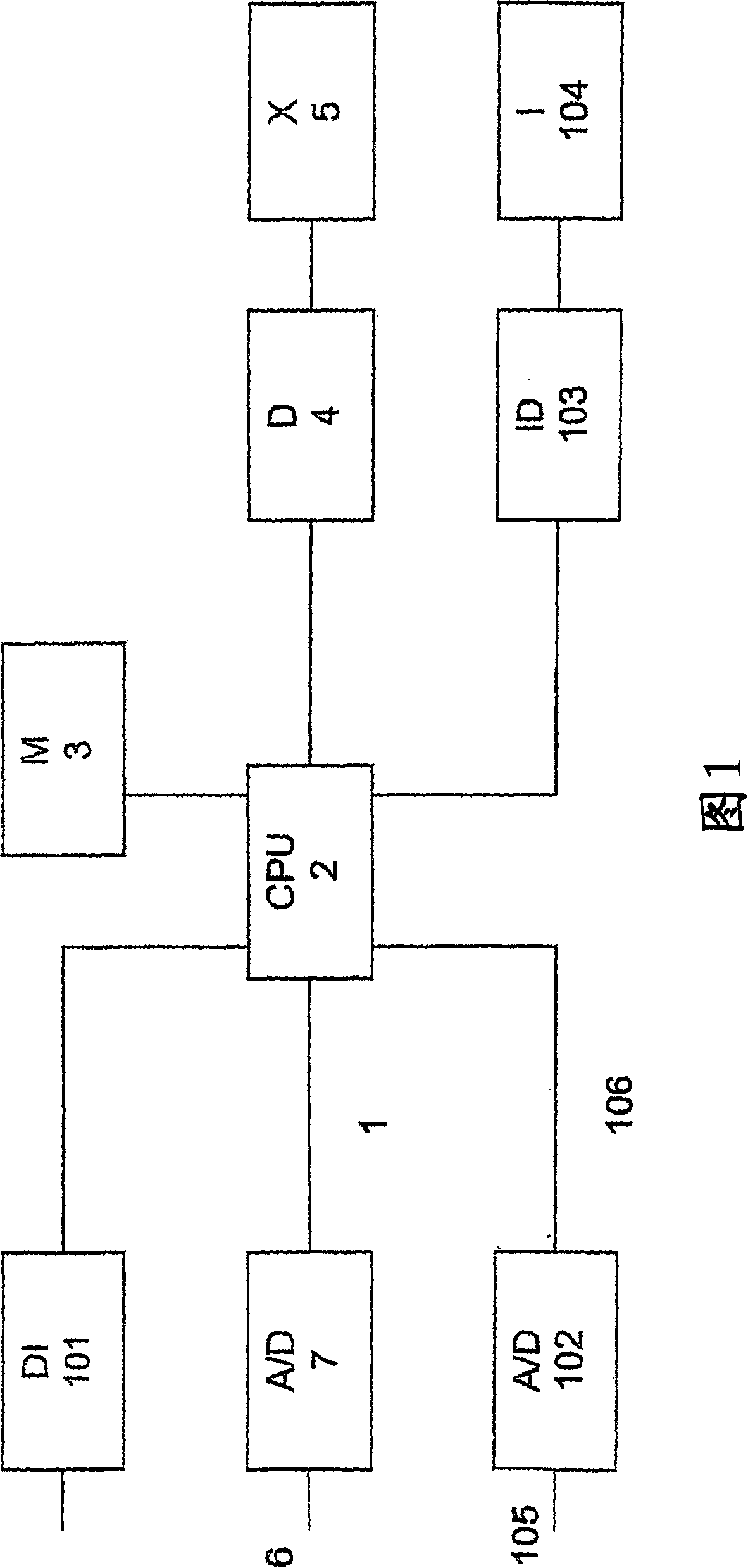

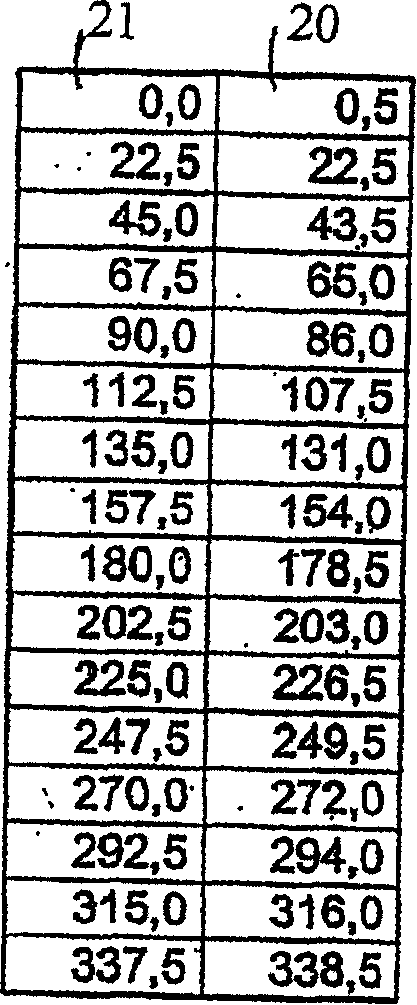

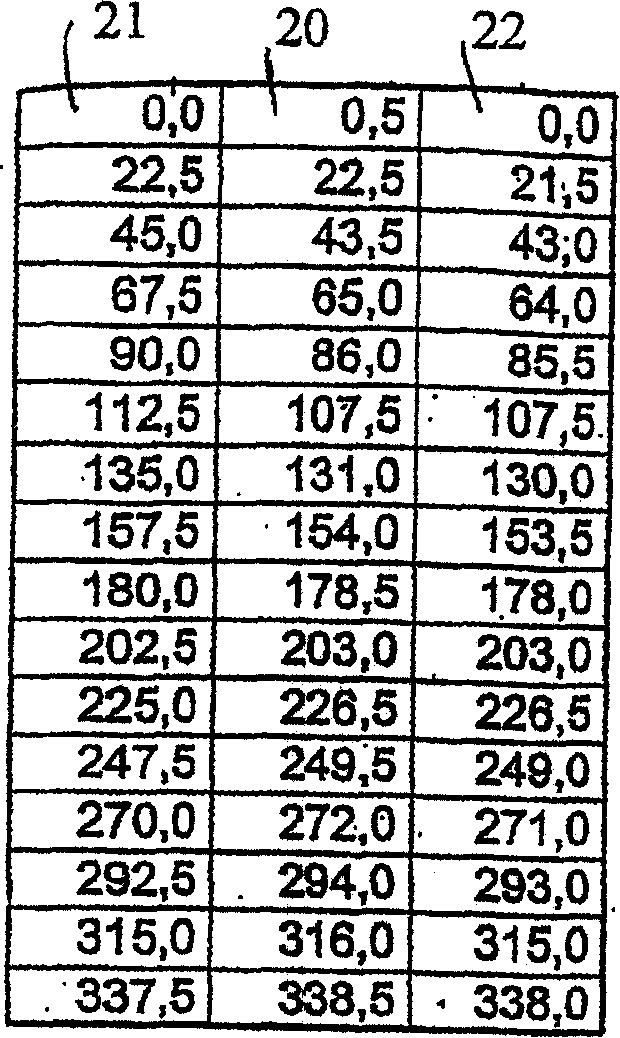

Cross coil instrument with a predefined characteristic

InactiveCN100394191CNot easy to static electricityReduced calibration costsThermometer detailsElectrical measurement instrument detailsDigital storageComputer science

The present invention relates to the visual representation of an input value, and provides an instrument, which can be given any predefined characteristic of its visual display. Cross-coil instrument is provided, said cross-coil instrument comprising a driver for the instrument characterized in that it further comprises a digital input terminal, a predetermined characteristic of the instrument stored as a map of input / output values in a digital memory and a microprocessor, said input value being a value represented visually by the cross-coil instrument, said output value being the value applied to the cross-coil instrument to visual represent the input value.

Owner:戴夫

Heat-conducting weather-resistant anti-radiation protective film for display screen and preparation method of protective film

InactiveCN108285617AImprove radiation protection performanceGood weather resistanceEpoxyHeat conducting

The invention discloses a heat-conducting weather-resistant anti-radiation protective film for a display screen and a preparation method of the protective film. The protective film comprises, by weight, 20-30 parts of epoxy resin, 10-14 parts of polyurethane resin, 4-6 parts of modified silicon dioxide, 10-16 parts of methyl methacrylate, 10-12 parts of poly-ethyl silicate, 4-6 parts of ethyl acrylate, 8-10 parts of anti-radiation additives, 5-7 parts of nano additive, 10-16 parts of acid ester mixture, 4-6 parts of flame-retardant additive, 5-7 parts of processing aid and 2-3 parts of coupling agent. The protective film is excellent in mechanical property, glossiness, light transmittance and heat shrinkage performance, good in scratch resistance, uniform in heat dissipation, capable of preventing radiation and excellent in weather resistance, and has certain fireproof and flame-retardant performance. The preparation method is safe and reliable in raw material component, harmless to human bodies and environments, low in cost, simple in process, easy to operate, capable of achieving industrial production, high in practical value and good in application prospect, and the raw materials are easy to obtain.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Environment-friendly high-strength stone-plastic board and preparation method thereof

The invention discloses an environment-friendly high-strength stone-plastic board. The environment-friendly high-strength stone-plastic board comprises the following raw materials in parts by weight: 10-16 parts of marble powder, 8-12 parts of fly ash, 10-14 parts of volcanic ash, 6-10 parts of talcum powder, 17-27 parts of polyethylene, 8-10 parts of chlorinated polyethylene, 4-6 parts of nano-sized titanium dioxide, 2-4 parts of nano-sized zinc oxide, 2-5 parts of a lubricant, 2-3 parts of a plasticizer, 1-3 parts of a stabilizer, 2-4 parts of an antistatic agent and 3-5 parts of a silane coupling agent. The environment-friendly high-strength stone-plastic board combines the advantages of stone and plastic, not only has the appearance like natural stone, but also is relatively light in weight, relatively high in strength, anti-static, non-friable and relatively environment-friendly; meanwhile, according to a preparation method of a sealing material provided by the invention, raw material components are safe, reliable, harmless to the environment and easy to obtain, the cost is relatively low, the process is succinct, the operation is easy and the industrial production is easily implemented, so that the preparation method has a relatively high practical value and a good application prospect.

Owner:合肥市淑芹美装饰工程有限公司

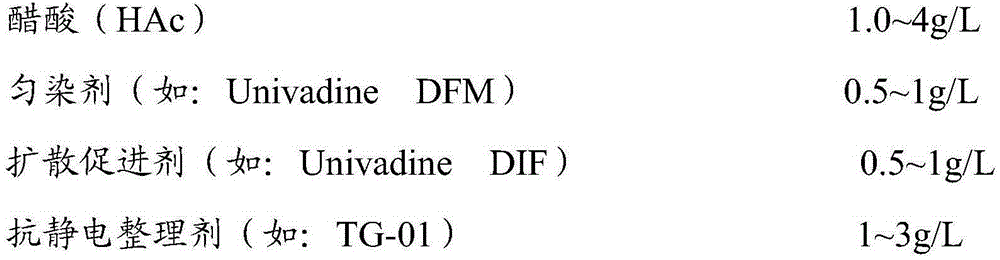

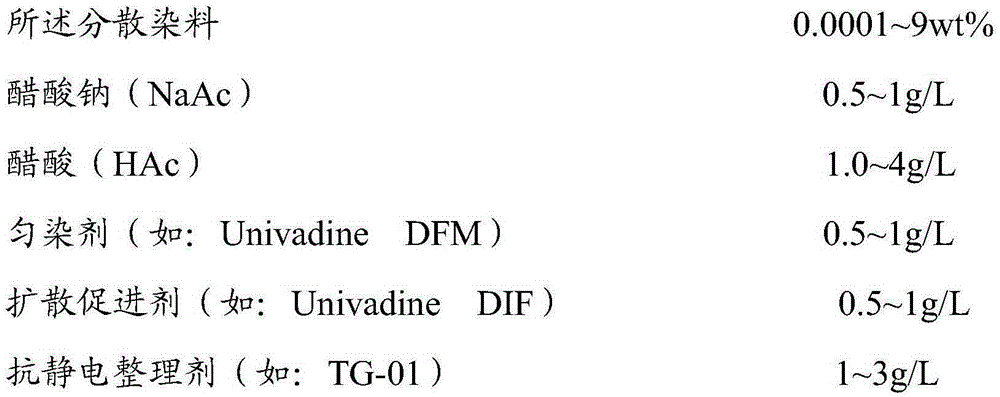

3A-grade natural antibacterial anti-mite kapok fabric and preparation method thereof

PendingCN113445187AAchieve antibacterial effectNot easy to generate static electricityWeft knittingMulti-ply fabricsPolyesterPolymer science

The invention provides a 3A-grade natural antibacterial anti-mite kapok fabric and a preparation method thereof. The kapok fabric is prepared from the following fiber raw materials in percentage by mass of 50-90% of main body fiber, 10-40% of kapok fiber and 0-10% of elastic fiber, wherein the total of the three components is 100%. The main body fiber is selected from cotton fiber, regenerated cellulose fiber, polyester, nylon, hemp, wool, cashmere and silk. The preparation method of the kapok fabric comprises the following steps of (1) pretreating natural kapok fibers by using a kapok pretreatment aid; (2) mixing and opening the kapok fiber, the main body fiber and the elastic fiber, then carding, drawing and spinning to obtain kapok blended yarns; (3) weaving the kapok blended yarns into gray fabric of single jersey or jacquard weave fabric; and (4) carrying out desizing, refining and bleaching pretreatment on the gray fabric, and then carrying out direct dyeing or reactive dye dyeing, soaping, setting, softening and after-finishing.

Owner:素湃科技(上海)有限公司

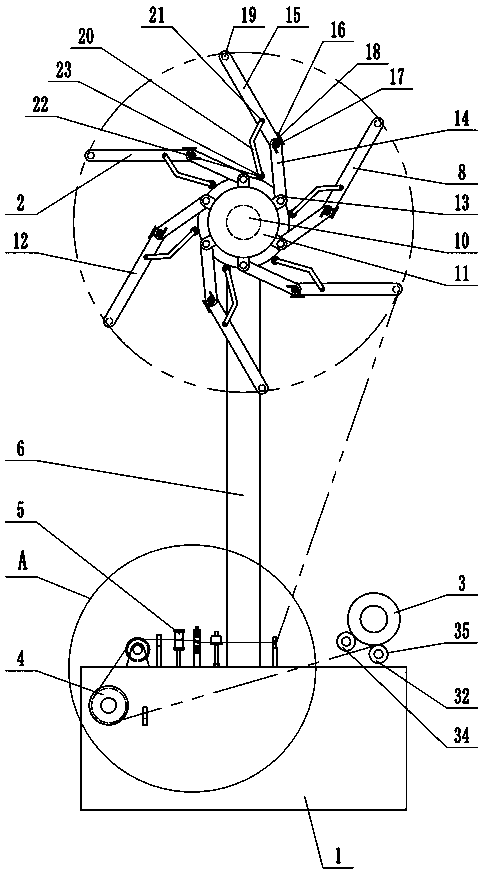

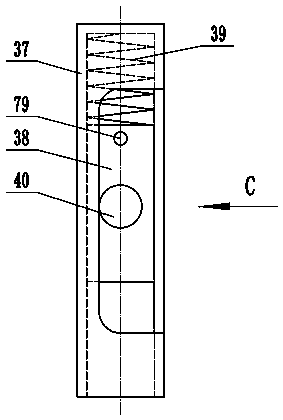

Reeling equipment for wool yarn

InactiveCN111232744AGuaranteed stabilityEasy accessFilament handlingTextiles and paperYarnStructural engineering

The invention provides reeling equipment for wool yarn, and belongs to the technical field of textile machines. The reeling equipment comprises a reeling rack, a reeling mechanism, an unreeling mechanism, a guide mechanism and a hair removing and waxing mechanism. A reeling frame of the reeling mechanism is rotationally arranged on one side of a reeling bearing box, three or more reeling frame assemblies are evenly arranged on a reeling frame supporting disc, and the unreeling mechanism comprises an unreeling bearing assembly and an unreeling compressing assembly. An unreeling bearing slidingblock of the unreeling compressing assembly is slidably and rotationally arranged in an unreeling compressing bearing tube, an unreeling shaft is rotationally arranged on one side of the unreeling bearing sliding block, and the unreeling shaft penetrates through a tube replacing groove of the unreeling compressing bearing tube. The hair removing and waxing mechanism is arranged between a second guide screen ad a guide ring, and comprises a tensioning assembly, a hair removing assembly and a waxing assembly. According to the reeling equipment, fast discharging of hank yarn can be achieved afterreeling is completed, hair can be effectively removed in the reeling process of the wool yarn, and the glossiness and elasticity of the wool yarn are improved.

Owner:周顺尧

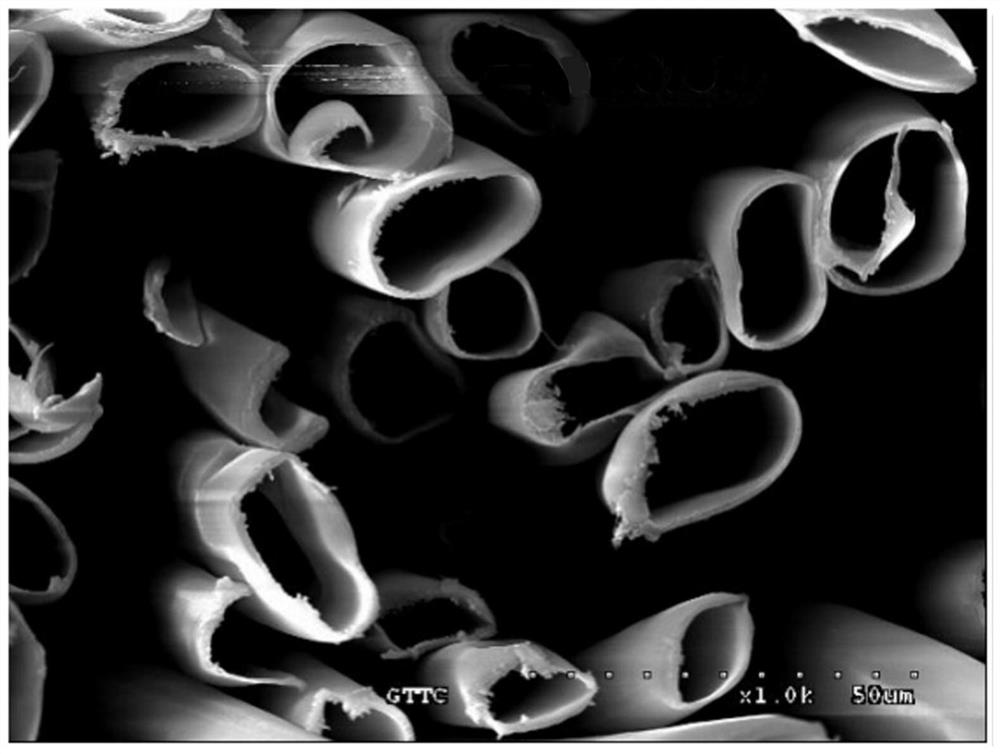

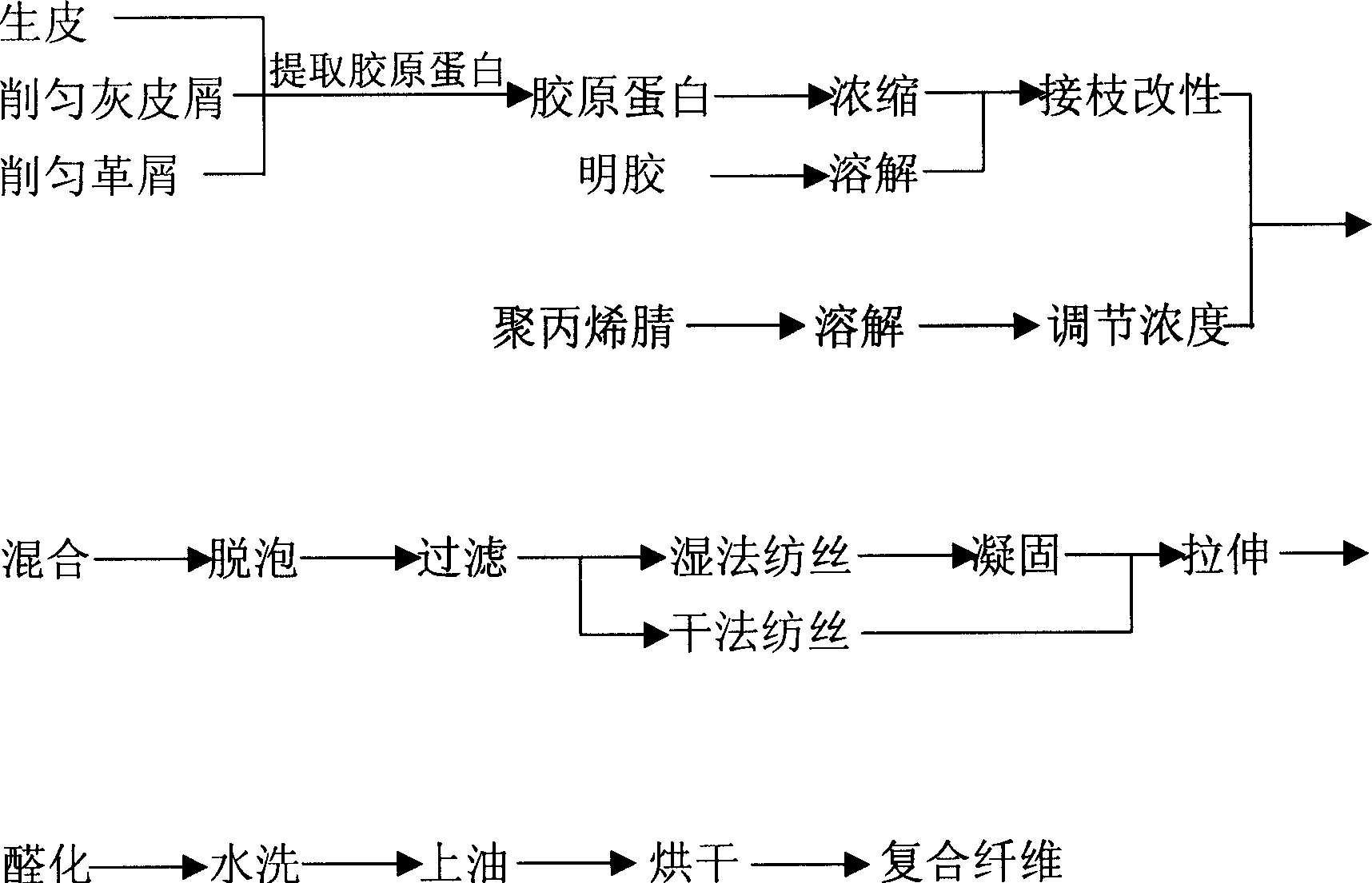

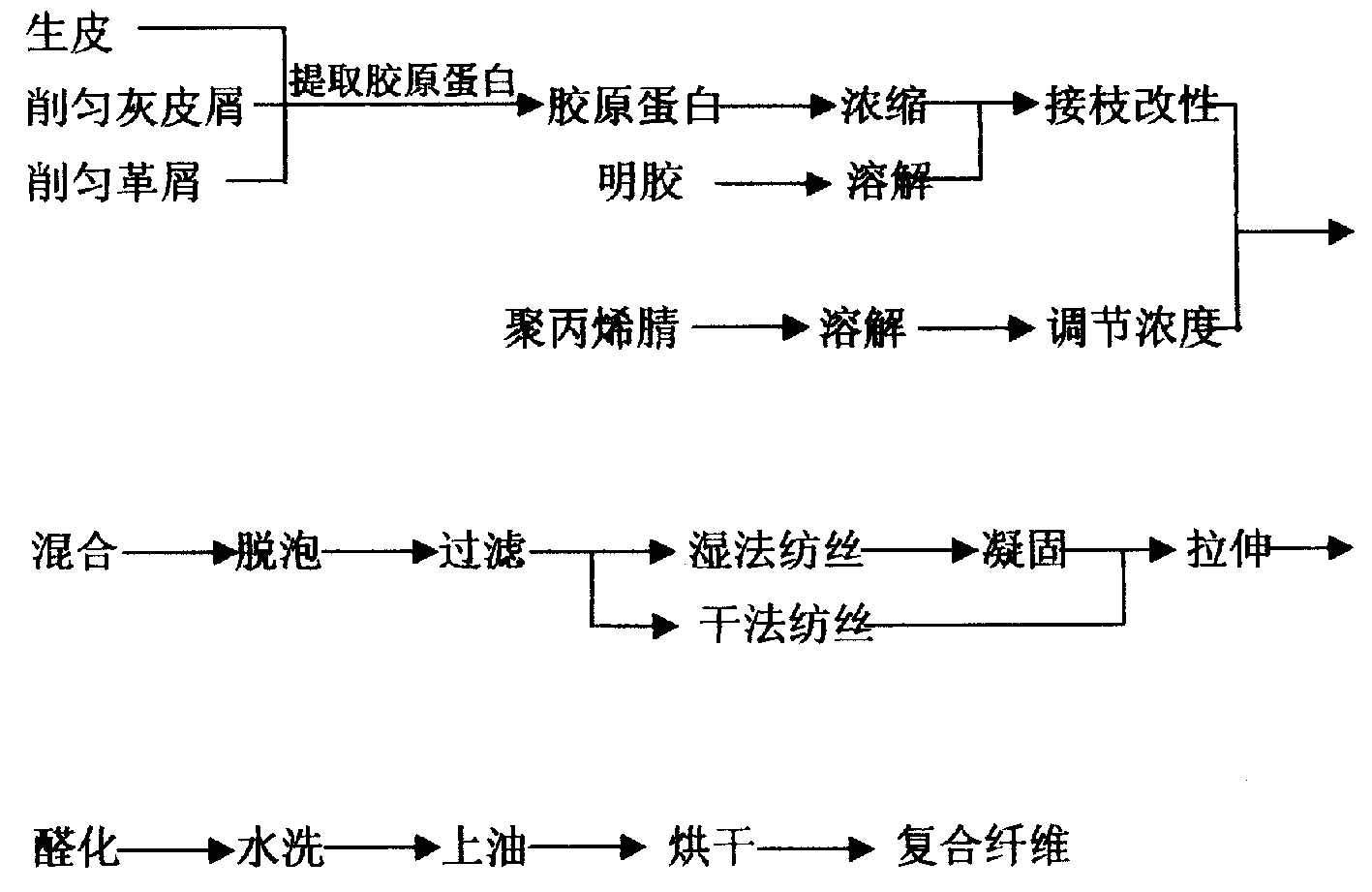

Collagen protein-polyacrylonitrile composite fiber and its preparation method

InactiveCN1243140CComfortable to wearGood hygroscopicityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolymer scienceSpinning

A composite collagen-polyacrylonitrile fibre is prepared from the collagen extracted from raw hide or the leftover of leather through graft polymerizing between said collagen and acrylonitrile or other end-type monomers, mixing with polyacrylonitrile to obtain dope, defoaming filtering, spinning, drafting and aldehydizing. It has high affinity to human skin and high hydroscopicity.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Interior decoration coating containing diatomite and having formaldehyde removal function

InactiveCN108329761APastel colorLong lasting colorStarch dervative coatingsAntifouling/underwater paintsEmulsionPhysical chemistry

The invention relates to an interior decoration coating containing diatomite and having a formaldehyde removal function. The coating is mainly prepared from components in percentage by mass as follows: 15%-35% of diatomite, 0.2%-1% of a dispersant, 0.2%-0.5% of sodium alginate, 15%-25% of modified starch, 10%-17% of a synthetic emulsion, 6%-13% of nano titanium dioxide, 5%-12% of talc powder, 0-30% of filler, 0.5%-2% of a silver ion antibacterial agent, 1%-5% of an aid, 0.3%-0.5% of a wetting agent, 0.2%-0.5% of an antifoaming agent and the balance of water. In conclusion, the interior decoration coating has the advantages that the coating has wide raw material source, low cost, safety, environmental friendliness and high formaldehyde adsorption capacity.

Owner:德马科起重机械有限公司

Production process of diatom ooze and activated carbon composite indoor decorative coating

InactiveCN108329778ANo static electricityNot easy to static electricityAntifouling/underwater paintsPaints with biocidesDisinfectantMaterials science

The invention relates to a production process of a diatom ooze and activated carbon composite indoor decorative coating. The coating is prepared from the following raw materials in parts by mass: 0.5-1 part of a dispersing agent, 0.1-2 parts of a surfactant, 0.4-0.8 parts of an antifoaming agent, 0.8-3.5 parts of ethylene glycol, 10-25 parts of titanium dioxide, 25-35 parts of diatomite, 15-45 parts of pure acrylic emulsion, 0.8-1.5 parts of a polyurethane thickener, 0.1-0.2 parts of a preservative, 0.2-0.7 parts of a mold inhibitor, 1-2.5 parts of a coalescing agent, 20-30 parts of water and10-15 parts of activated carbon. The coating has the advantages of adopting widely sourced raw materials and being cheap, safe, environmentally friendly, disinfectant, mold-proof, deodorant and capable of purifying air.

Owner:德马科起重机械有限公司

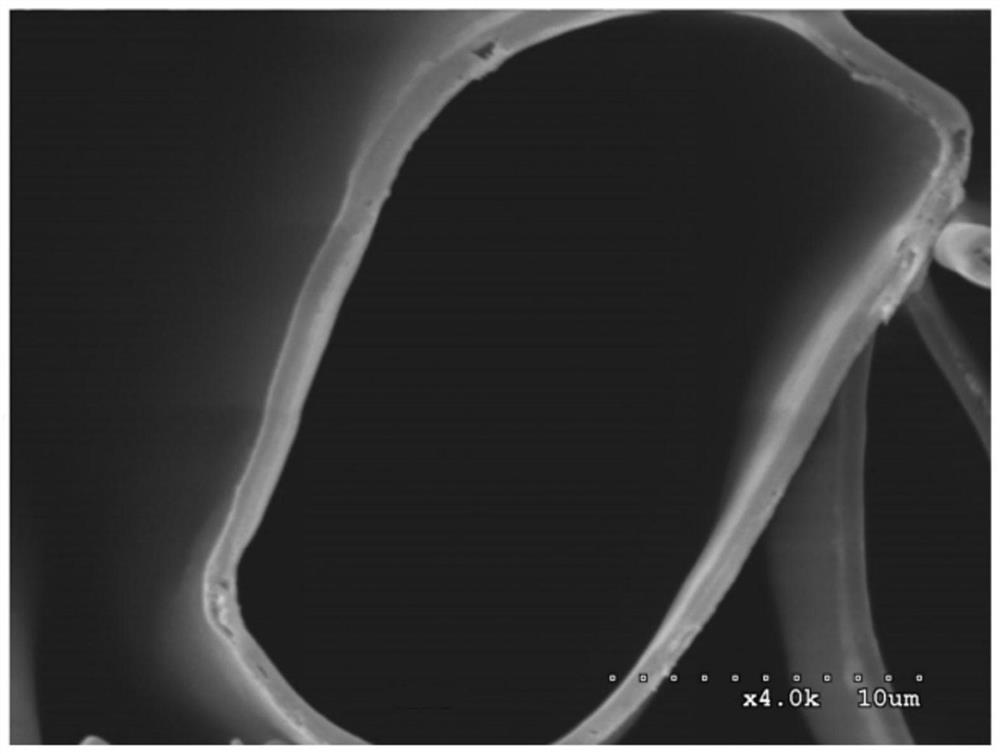

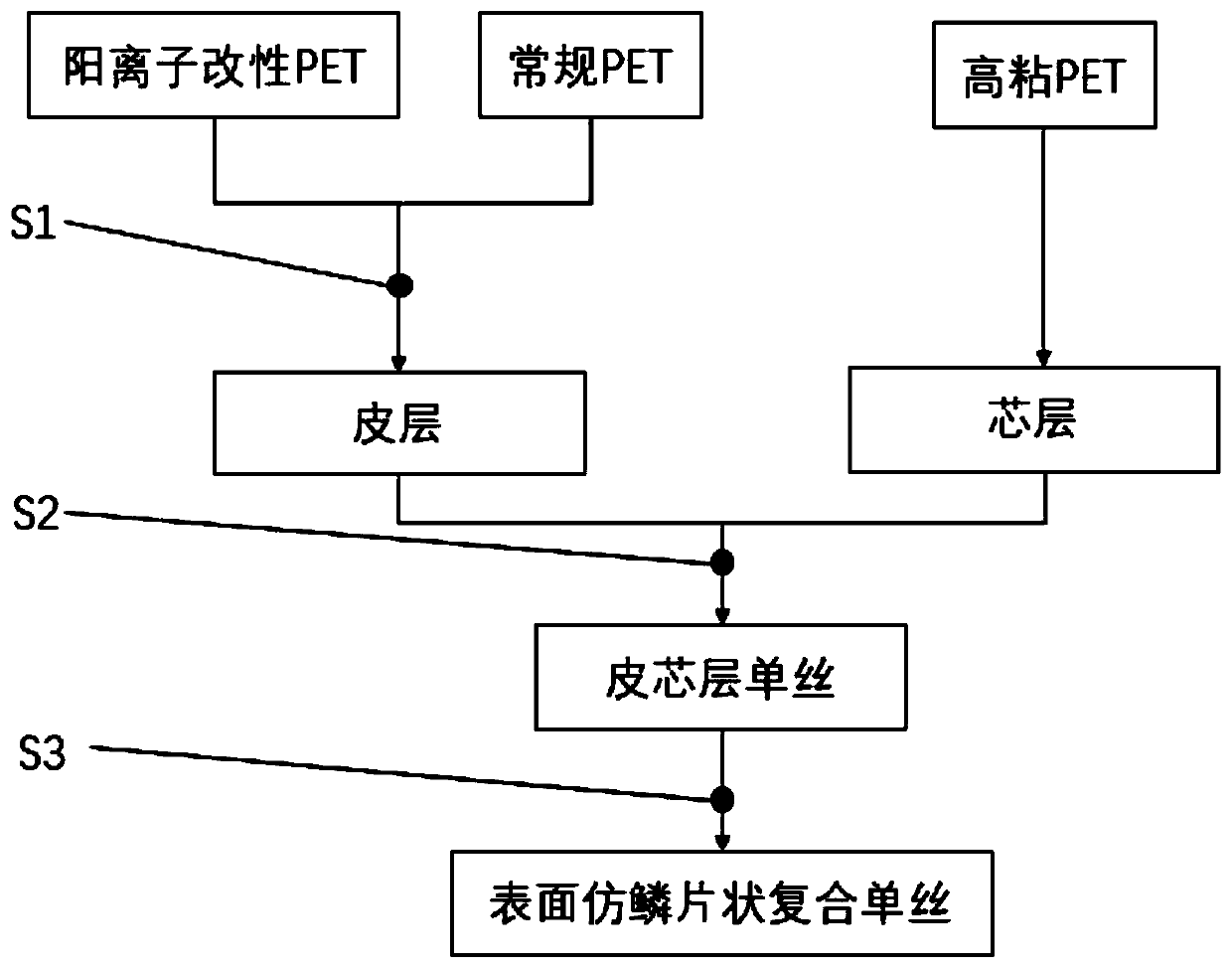

Surface scale-like composite monofilament and preparation method and application thereof

ActiveCN111424324AGood physical propertiesEasy to cleanWigsFibre typesPolymer scienceVisual perception

The invention relates to the field of fibers, and provides a surface scale-like composite monofilament and a preparation method and application thereof in order to solve the technical problem that fibers imitating natural hair are poor in visual fidelity. The surface scale-like composite monofilament comprises a core layer and a surface layer, wherein the core layer is made of high-viscosity PET,and the surface layer is obtained through alkali de-weighting of a mixture of conventional PET and cationic modified PET. The surface layer of the surface scale-like composite monofilament is in a dispersed concave hole shape, the fineness is 6-85 dtex, the strength is 5.2-8.6 CN / dtex, and the rigid modulus is 210-250 CN / dtex. Due to dispersed distribution of concave holes, the refractive index ofthe surface of the surface scale-like composite monofilament exhibits a multi-dimensional difference, has a special gloss sense similar to the scale-like vision of natural hair, has little differenceto visual perception of the natural hair, and is more visually vivid. The surface scale-like composite monofilament has excellent physical properties, is not prone to generating static electricity, easy to take care of and free of toxins and odors, and can meet various natural-hair-imitating modeling process requirements and usage requirements.

Owner:WUXI JINTONG CHEM FIBER

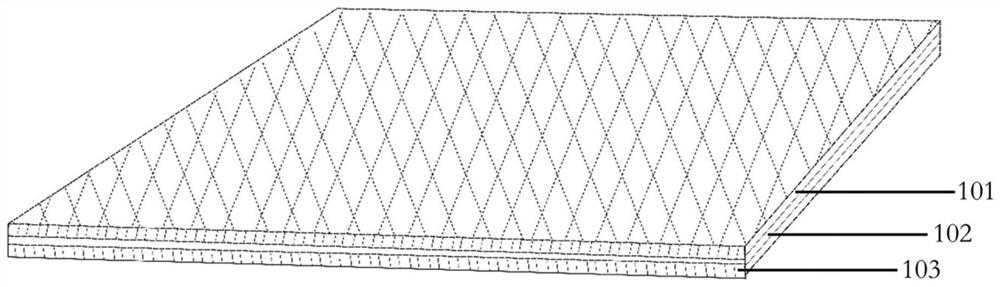

Composite non-woven fabric and preparation method thereof

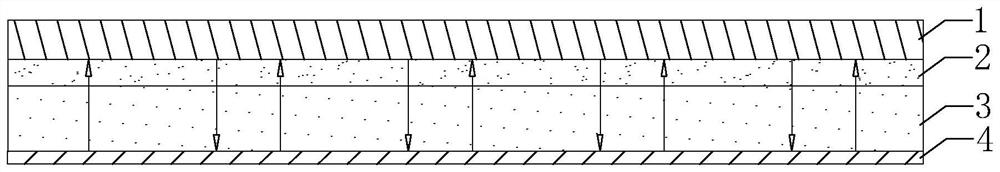

PendingCN114834108ANot easy to static electricityReduce the probability of static electricity generated by frictionElectroconductive/antistatic filament manufactureSynthetic resin layered productsPolymer scienceNonwoven fabric

The invention relates to a composite non-woven fabric and a preparation method thereof, the composite non-woven fabric comprises a skin-friendly layer, a transition layer, a base layer and a protective layer, the transition layer is located between the skin-friendly layer and the base layer, the skin-friendly layer is bonded and matched with the transition layer, the transition layer is fixedly connected with the base layer, and the base layer is bonded and matched with the protective layer; the base layer is formed by lapping modified polypropylene filaments; the modified polypropylene filament comprises the following raw materials in parts by weight: 80-120 parts of a polypropylene base material; 6-8 parts of dioctadecyl ammonium chloride; 8 to 12 parts of 4-[(heptadecafluorononyl) oxy] sodium benzenesulfonate; 6-8 parts of white mica powder; 2-6 parts of an antibacterial auxiliary agent and 0.5-1.5 parts of a lubricant. The composite non-woven fabric has the advantages that the composite non-woven fabric is not prone to generating static electricity, and therefore the dust adsorption probability is reduced when the composite non-woven fabric serves as a surgical gown fabric.

Owner:DONGGUAN KEDI IND CO LTD

Flame-retardant insulation liner material for electric safety helmet and preparation method of flame-retardant insulation liner material

The invention discloses a flame-retardant insulation liner material for an electric safety helmet. The flame-retardant insulation liner material contains the following raw materials in parts by weight: 70-90 parts of high-fluidity ABS resin, 3-7 parts of nano-silicon dioxide, 2-6 parts of nano-silicon nitride, 1-3 parts of a silane coupling agent, 2-3 parts of polyvinyl alcohol, 2-3 parts of chitosan, 8-12 parts of a flame retardant agent, 8-14 parts of short fibers, 2-6 parts of a flame retardant synergist, 5-7 parts of a processing aid, 0.5-1.5 parts of an antioxidant, 0.4-1.2 parts of a light stabilizer and 1-2 parts of a compatilizer. The liner material disclosed by the invention has excellent mechanical properties, strong strength and good flame retardance, puncture resistance, shock absorption performance and electrical insulation property and can resist impact and aging; meanwhile, the preparation method of the liner material has the beneficial effects that the raw material components are safe, reliable and harmless to the environment, the raw materials are easily available and relatively low in cost, the process is simple, clear and easy in operation, the industrial production is easily realized, and the preparation method has relatively high practical values and good application prospects.

Owner:山东励仙电力工程有限公司

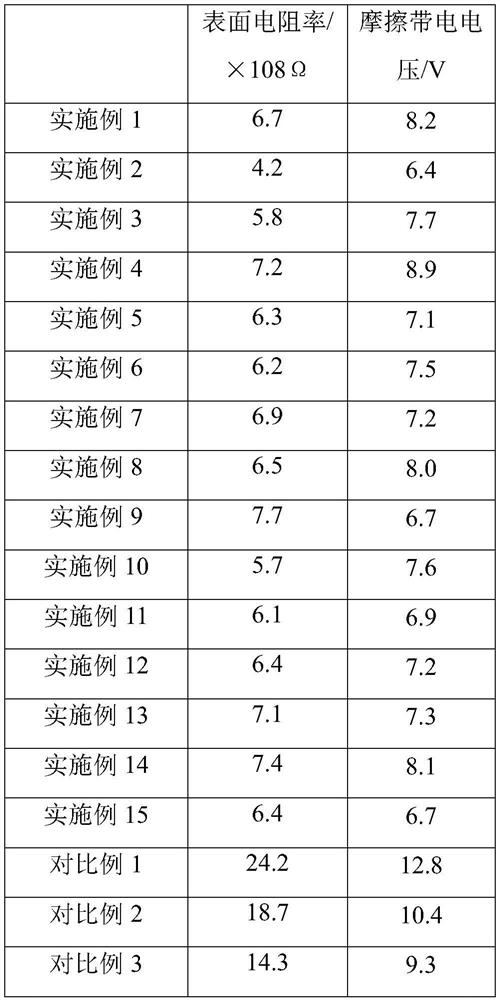

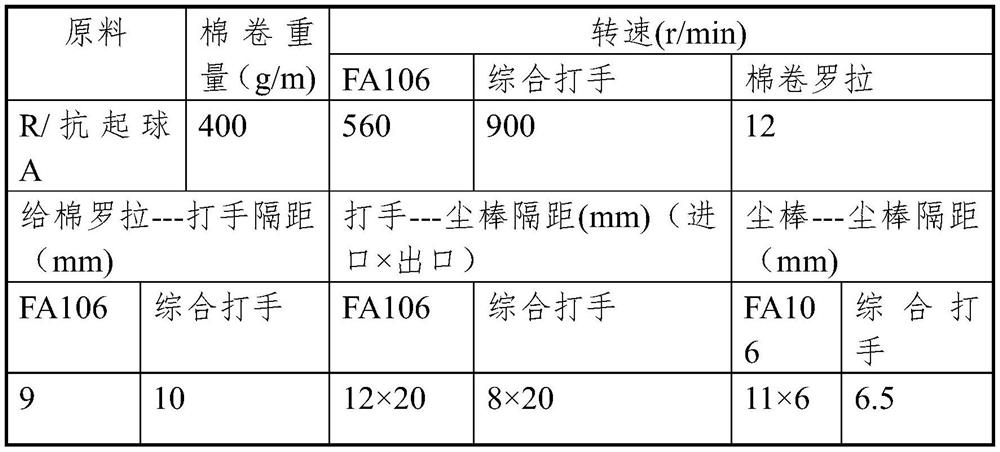

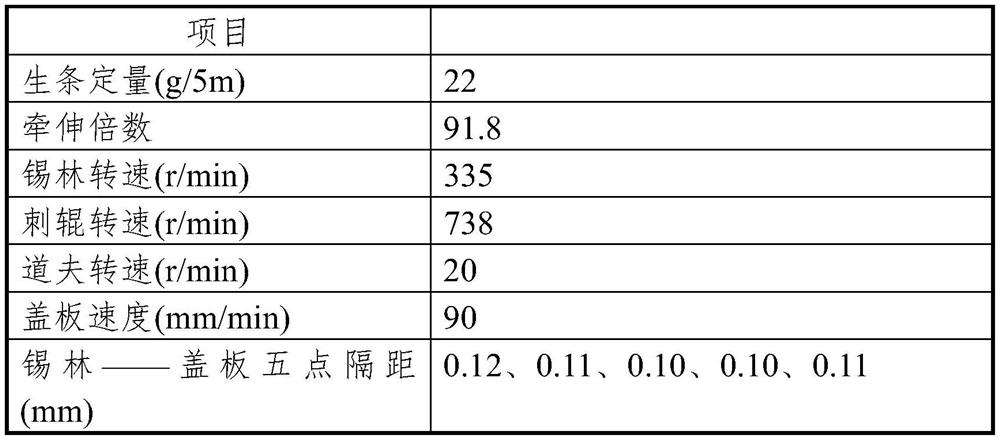

Anti-pilling and high-twist covering yarn and preparation method thereof

InactiveCN113832583ANot easy to generate static electricityNot easy to static electricityYarnPolyesterYarn

The invention discloses anti-pilling and high-twist covering yarn and a preparation method thereof. The anti-pilling and high-twist covering yarn is of a skin-core structure; the mass fraction of a skin layer ranges from 70% to 90%, and the mass fraction of core yarn ranges from 10% to 30%; the material of the skin layer includes anti-pilling acrylic fibers and at least one of viscose, modal, polyester, fine wool, spandex, acrylic fibers, cashmere and cotton threads; and the core yarn is pre-oriented yarn. The invention further discloses the preparation method of the anti-pilling and high-twist covering yarn. When a fabric made of the anti-pilling and high-twist covering yarn is rubbed, fiber ends are not prone to stretching out of a fabric cover to form fluffs or small ball protrusions; and the anti-pilling and high-twist covering yarn is good in hygroscopicity, not prone to generating static electricity, relatively good in placeable performance, smooth and soft in hand feeling, good in drapability, capable of maintaining a three-dimensional shape for a long time and capable of conforming to the new trend of current world clothes.

Owner:江阴市茂达棉纺厂有限公司

a cleaning powder

ActiveCN110819479BImprove performanceEasy to cleanDetergent mixture composition preparationOrganic non-surface-active detergent compositionsMetallurgyOptical glass

Owner:广州森波化工科技有限公司

Organic-inorganic antibacterial and antifouling interior wall paint and preparation method thereof

ActiveCN112920667BChemically resistantFlame retardantFireproof paintsAntifouling/underwater paintsMeth-Kaolin clay

The invention relates to the technical field of coatings, in particular to an organic-inorganic antibacterial and antifouling interior wall coating and a preparation method thereof. Inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion, zeolite-loaded silver, silica gel-loaded silver, functional filler, calcined kaolin, wollastonite powder, lime calcium powder, Tuyile HD‑20 dispersant, Tuyile inorganic powder DS‑ 195 dispersant, 2,4,7,9-tetramethyl-5-decyne-4,7-diol, deionized water. The invention uses inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion as the base material, and uses zeolite silver-loaded and silica gel-loaded silver as composite inorganic antifungal agents, so that the coating has the chemical corrosion resistance, flame retardancy and fire prevention of inorganic coatings , green and environmental protection characteristics and the advantages of strong adhesion and good scrub resistance of organic coatings ensure that the coatings are safe and non-toxic, have excellent anti-mildew properties, and have a long effective period of anti-mildew.

Owner:ZIBO VOCATIONAL INST

Zipper cloth, zipper cloth preparation method and zipper

ActiveCN109295723AGood hygroscopicityNot easy to static electricitySlide fastenersFibre typesPolyesterEngineering

The invention provides zipper cloth, a zipper cloth preparation method and a zipper. The zipper cloth preparation method includes steps: A) deoiling polyester cloth to obtain pretreated polyester cloth; B) modifying the pretreated polyester cloth in modifying agent solution, and drying to obtain the zipper cloth, wherein a modifying agent in the modifying agent solution is a cool finishing agent TK COOL SP-6, and the modifying temperature is 40-60 DEG C. By modification of the de-oiled polyester cloth at a specific temperature through the specific modifying agent, the obtained zipper cloth isexcellent in moisture adsorption and less prone to static electricity generation and shrinkage, and the zipper made of the cloth is high in strength. In addition, the zipper cloth preparation method is simple, feasible, mild in operating condition and low in equipment requirement.

Owner:ZHEJIANG WEIXING IND DEV

Natural plant type paint and its preparation method

The present invention relates to a natural plant type coating and its preparation method. Said coating is formed from high-molecular film-forming material, pigment, adjuvant and solvent. It is characterized by that the oil material adopted in the high-molecular film-forming material contains 30-40 portions of linseed oil, 35-45 portions of limonene, 5-15 portions of polybasic alcohol, the polybasic acid contains 8-15 portions of phthalic anhydride and 2-5 portions of trimellitic anhydride, the adjuvant is 0.02-0.1 portion of catalyst lithium hydroxide, the dryer is 1-3 portions of composite rare earth, and the solvent contains 5-10 portions of pine cone oil and 5-10 portions of terpineol, the above-mentioned raw materials are mixed to obtain the invented film-forming material. Besides, it adopts deionized water, adds 18-35 portions of pigment titanium dioxide, adds drying, dispersing, anti-freezing, defoaming, anti-corrosion and film-forming adjuvants, and adds medicinal talcum powder and natural calcium carbonate and stirs them to obtain slurry material for stand-by, then said invention utilizes 10-20 portions of film-forming material to make emulsification, adds deionized water and the above-mentioned slurry material, and adds thickening agent, mixes them so s to obtain the invented coating.

Owner:TIANJIN LIUHONG TECH DEV

Polyester woven label suitable for non-ironing garments and preparation method thereof

ActiveCN104313922BEfficient removalDecreased fastnessDyeing processLiquid/gas/vapor yarns/filaments treatmentPolyesterYarn

The invention discloses a method for preparing a polyester woven label suitable for non-ironing garments, which comprises the following steps: (1) preparing yarn; (2) writing flowers; (3) weaving the label. In the present invention, the yarn prepared by a specific method cooperates with the corresponding tissue structure, density, and interweaving point parameters, and the temperature of the woven label ironing board is set at 145-155 °C, and the ironing time is 4-7 minutes. The prepared polyester woven label can save The subsequent washing process not only shortens the production cycle and reduces the production cost, but also the color fastness of all aspects of the woven label can be controlled at level 4 or above, and the shrinkage rate is controlled below 3%. Wrinkle, fully meet the requirements of non-iron garments.

Owner:广东康派环创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com