Polyester woven label suitable for non-ironing garments and preparation method thereof

A polyester weaving label and garment technology, applied in the field of clothing accessories, can solve the problems of water resource additive consumption, increase production time, prolong production cycle, etc., and achieve the effects of reducing production cost, not easy to generate static electricity, and less dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention is a method for preparing polyester woven labels suitable for non-iron garments, including the following steps:

[0032] (1) Preparation of yarn: pre-treat the polyester grey yarn, then use the compound dyeing solution for dyeing, and finally perform post-processing to obtain;

[0033] The pretreatment process is: placing the polyester yarn in a pretreatment solution with a bath ratio of 1:1-20, heating to 80-90°C for 10-30 minutes, and then washing once at 40-60°C;

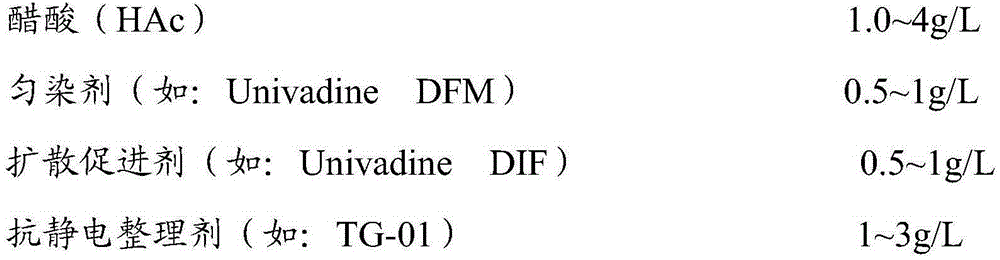

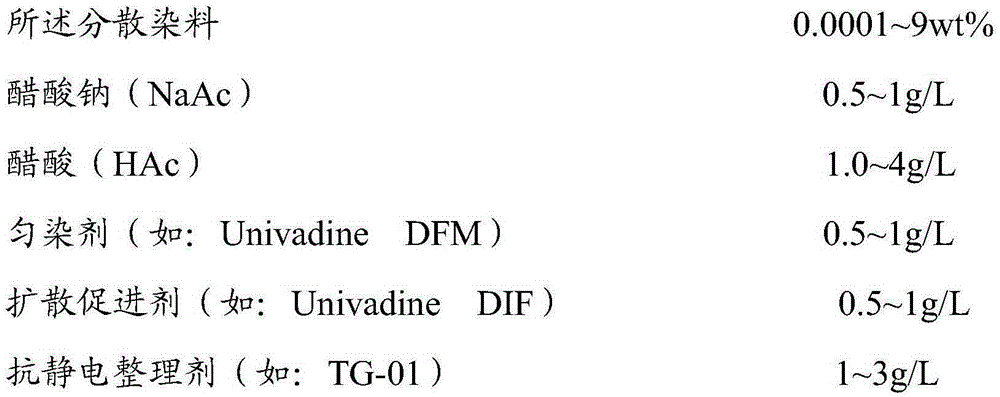

[0034] The formula of the pretreatment solution is as follows:

[0035] Efficient degreasing agent (such as JintergeLCF-185) 0.5~1g / L

[0036] Oligomer remover (such as: TF-205) 1~2g / L

[0037] The balance is industrial soft water;

[0038] The dyeing process is: placing the polyester yarn processed by the pre-treatment process in a dyeing machine, adding the compound dyeing solution, running at room temperature for 5 to 10 minutes, and then operating at 1 to 2°C / min Increase the temperature to ...

Embodiment 1

[0074] In this embodiment, a method for preparing polyester woven labels suitable for non-iron garments includes the following steps:

[0075] (1) Yarn preparation method: pre-processing the raw material polyester yarn of the weaving label, adding a compound dyeing solution to dye it, and performing post-processing. The step parameters of each process are as follows:

[0076] Pre-treatment process: Put the raw material polyester yarn of the woven label in industrial soft water at a bath ratio of 1:10, add JintergeLCF-185 and TF-205, add 1g / L each, heat up at 90℃ and keep for 30min , Drain, wash once at 50℃, drain.

[0077] Dyeing process: Put the polyester yarn that has gone through the pre-treatment process in a high-temperature and high-pressure package dyeing machine, feed water to the same water level as the pre-treatment process, add NaAc, HAc, and the addition amount is 1g / L, 3g / L, Adjust the pH to 3.5-4.0, run at room temperature for 5 minutes, add HuntsmanTerasilYellowW-6GS...

Embodiment 2

[0086] In this embodiment, a method for preparing polyester woven labels suitable for non-iron garments includes the following steps:

[0087] (1) Yarn preparation method: pre-processing the raw material polyester yarn of the weaving label, adding a compound dyeing solution to dye it, and performing post-processing. The step parameters of each process are as follows:

[0088] Pre-treatment process: Put the raw material polyester yarn of the woven label in industrial soft water at a bath ratio of 1:10, add JintergeLCF-185 and TF-205, add 1g / L each, heat up at 90℃ and keep for 30min , Drain, wash once at 50℃, drain.

[0089] Dyeing process: Put the polyester yarn that has gone through the pre-treatment process in a high-temperature and high-pressure package dyeing machine, feed water to the same water level as the pre-treatment process, add NaAc, HAc, and the addition amount is 1g / L, 3g / L, Adjust the pH to 3.5, run at room temperature for 5 minutes, add HuntsmanTerasilYellowW-6GS, Hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com