Surface scale-like composite monofilament and preparation method and application thereof

A composite monofilament and scale-like technology, which is applied in the fiber field, can solve the problems of poor visual fidelity of chemical fibers, and achieve the effects of visual fidelity, easy cleaning and care, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the prior art, the chemical fibers used in imitation natural hair products or wig products have the advantages of cheap price and high durability of styling, but have the disadvantages of obvious difference in visual perception from natural hair and poor fidelity.

[0022] In order to solve the technical problem of poor visual fidelity of chemical fibers used in imitation natural hair products or wig products, Example 1 provides a composite monofilament with a surface imitating scales, including: the core layer has an intrinsic viscosity of 0.76 to 0.92 dL / g PET, the skin layer is obtained from a blend of PET with an intrinsic viscosity of 0.6-0.68dL / g and cationic modified PET through alkali reduction treatment; the skin layer covers the core layer; the surface layer of the scale-like composite monofilament is Discretely distributed concave holes, the scale-like composite monofilament has a fineness of 6-85dtex, a strength of 5.2-8.6CN / dtex, and a rigid modulus of 21...

Embodiment 2

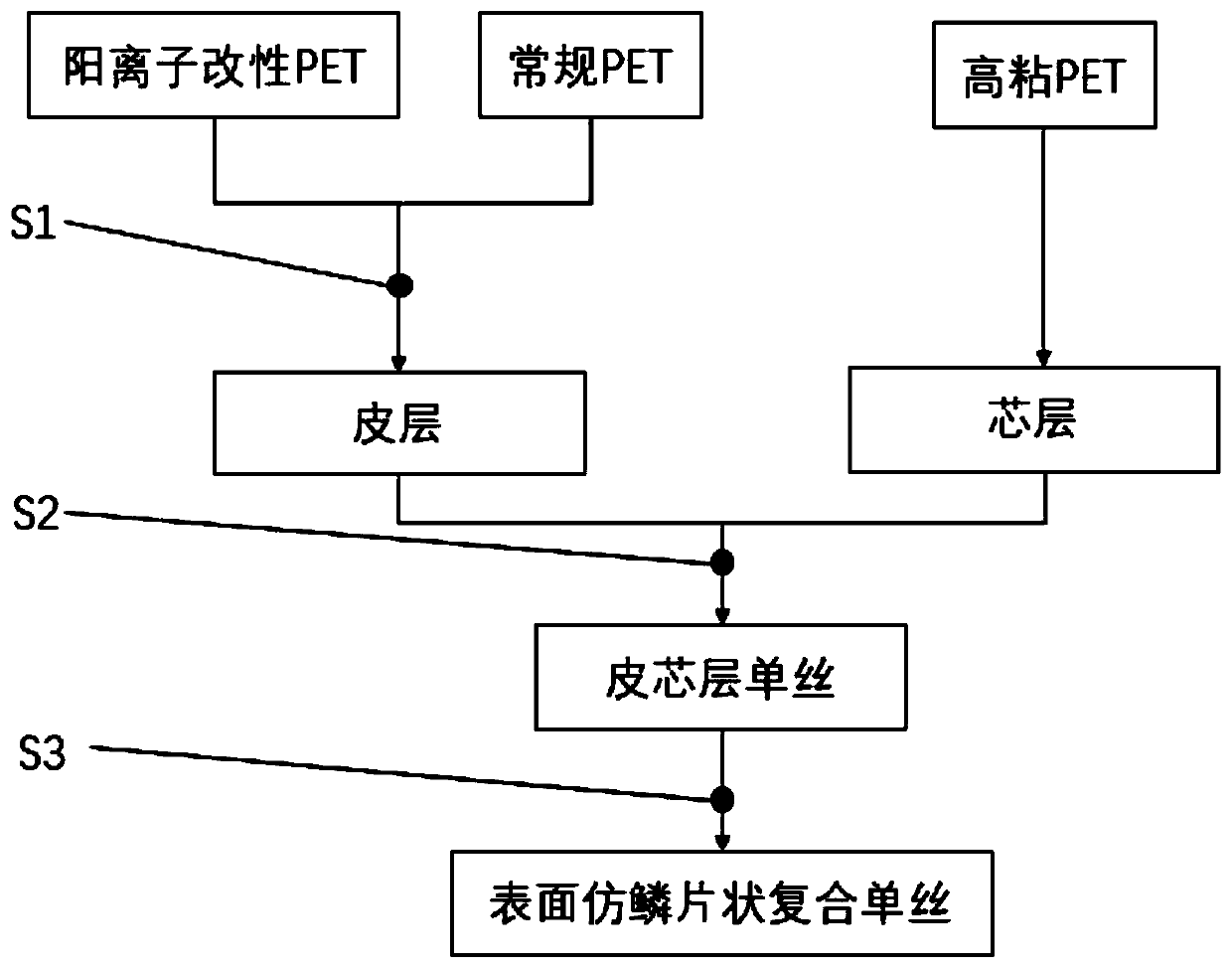

[0034] Embodiment 2 provides a method for preparing the surface imitation scale-like composite monofilament of embodiment 1, including the following steps, and the corresponding flow chart of some steps is as follows: figure 1 Shown:

[0035] In the step of preparing the raw material for the cortex (step S1), PET with an intrinsic viscosity of 0.6-0.68 dL / g and cationic-modified PET are blended by twin-screws and then granulated to obtain PET with an intrinsic viscosity of 0.6-0.68 dL / g and cationic-modified PET. Blends of PET;

[0036] In the step of preparing monofilaments of the skin and core layer (step S2), the core layer is selected from PET with an intrinsic viscosity of 0.76 to 0.92 dL / g, and the skin layer is selected from a blend of PET with an intrinsic viscosity of 0.6 to 0.68 dL / g and cationic modified PET. Melting, compound forming, stretching and setting treatment to obtain monofilament of skin core layer;

[0037] Alkali weight reduction treatment step (step ...

Embodiment 3

[0052] In the prior art, imitating natural hair is usually made of more expensive biological materials. Embodiment 3 provides an imitating natural hair, at least partially using the surface-imitating scale-like composite monofilament of embodiment 1. The imitation of natural hair provided in Example 3 uses a surface-imitation scale-like composite monofilament, and adopts cheap and easy-to-obtain raw materials and production equipment, which can realize mass production and reduce production costs. The imitation natural hair provided by Example 3 can produce a special luster similar to the imitation scale vision of natural hair due to the surface-imitation scale-like composite monofilament, which meets the modeling process requirements and use requirements of various imitation natural hairs, and has a broad market Prospect and use value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com