Anti-pilling and high-twist covering yarn and preparation method thereof

A technology of anti-pilling and core-spun yarn, which is applied in the direction of yarn, textiles and papermaking, etc. It can solve the problems affecting the appearance and wearer's feeling, and achieve the effect of smooth hand feeling, good hygroscopicity, and not easy to generate static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

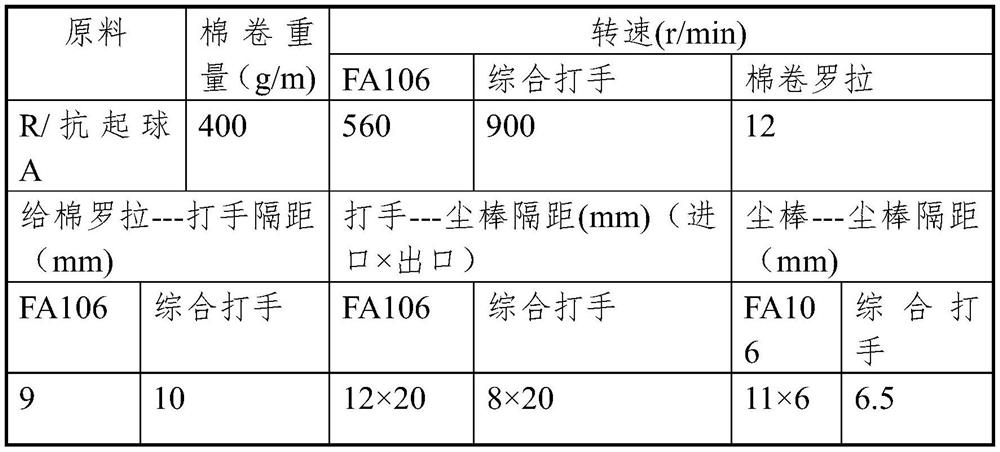

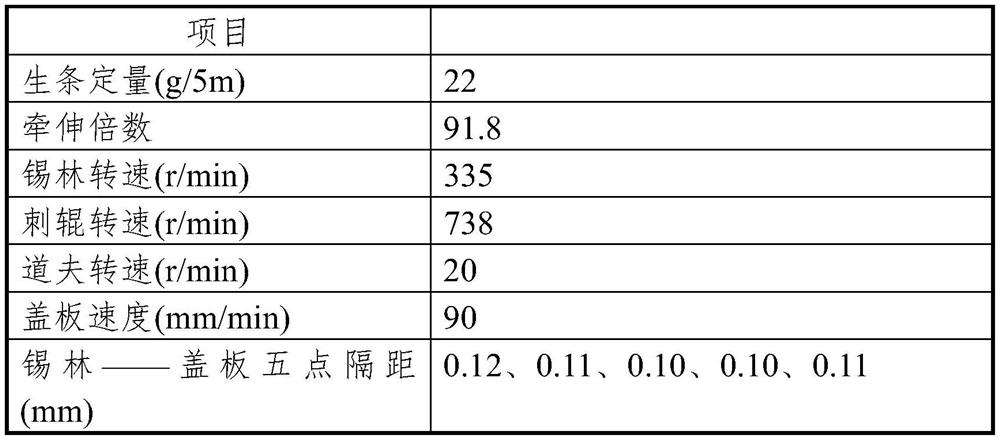

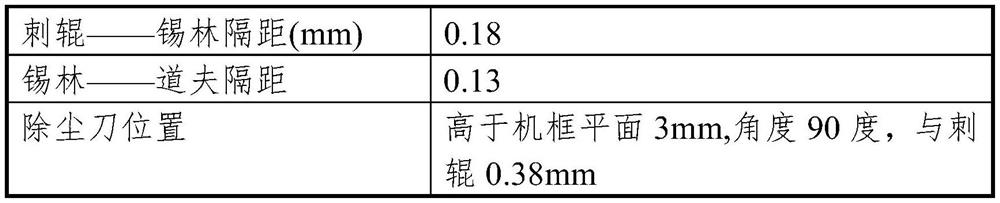

Method used

Image

Examples

Embodiment 1

[0039] An anti-pilling high-twisted core-spun yarn, comprising warp yarns, weft yarns and binding yarns, the binding yarns intertwine the warp yarns and the weft yarn layers perpendicular to each other to form a three-dimensional structure, the warp yarns, the weft yarns And the binding yarn is a sheath-core structure, the mass fraction of the warp yarn and the weft yarn cortex is 70%, the mass fraction of the core thread of the warp yarn and the weft yarn is 30%, and the warp yarn and the weft yarn have a mass fraction of 30%. The material of the skin layer includes anti-pilling acrylic fiber and viscose fiber; the core thread of the warp yarn and the weft yarn is PBT filament, and the specification is 20D. The composition of the binding yarn is: the mass fraction of the cortex is 80%, the mass fraction of the core thread is 20%, the material of the cortex includes 40% anti-pilling acrylic fiber, and 60% viscose fiber; the core thread is PBT filament, The specification is 30D...

Embodiment 2

[0042] An anti-pilling high-twisted core-spun yarn, comprising warp yarns, weft yarns and binding yarns, the binding yarns intertwine the warp yarns and the weft yarn layers perpendicular to each other to form a three-dimensional structure, the warp yarns, the weft yarns And the binding yarn is a sheath-core structure, and the composition of the warp is: a sheath-core structure, the mass fraction of the cortex is 80%, the mass fraction of the core thread is 20%, and the material of the cortex includes 40% anti-pilling acrylic fiber, and 60% viscose fiber; the core wire is PBT filament, the specification is 30D. The composition of the weft yarn is: the mass fraction of the cortex is 90%, the mass fraction of the core thread is 10%, the material of the cortex includes 50% anti-pilling acrylic fiber, and 50% viscose fiber; the core thread is PBT filament, the specification It is 40D. The composition of the binding yarn is: the mass fraction of the cortex is 80%, the mass fractio...

Embodiment 3

[0045] An anti-pilling high-twisted core-spun yarn, comprising warp yarns, weft yarns and binding yarns, the binding yarns intertwine the warp yarns and the weft yarn layers perpendicular to each other to form a three-dimensional structure, the warp yarns, the weft yarns And the binding yarn is a sheath-core structure, the mass fraction of the cortex of the warp yarn, the weft yarn and the binding yarn is 90%, the mass fraction of the core thread is 10%, and the material of the cortex includes 50% anti-pilling acrylic fiber , and 50% viscose fiber; the core wire is PBT filament, the specification is 40D.

[0046] The yarn density is 40tex, the weaving density and the number of weaving layers are 1000 threads / 10cm per layer in warp density, and 150 threads / 10cm in weft density in each layer; anti-pilling high-twist core-spun yarns are obtained by weaving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com