A kind of slate with suet jade touch and preparation method thereof

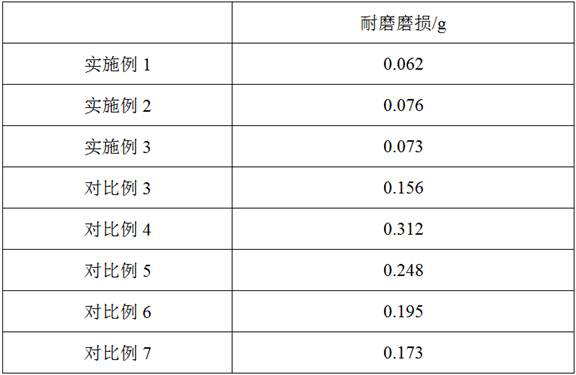

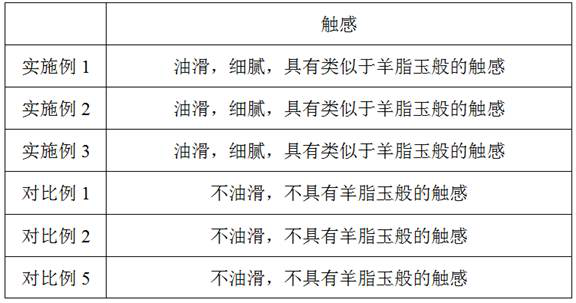

A suet and tactile technology is applied in the field of slate with suet jade touch and its preparation field, which can solve the problems of too many glass phases and insufficient wear resistance, and achieve the effect of good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] White jade slab having a tactile, from bottom to top comprises a body layer, a glaze layer, the glaze layer is formed by applying the glaze by sintering suet on the body layer.

[0033] The suet glaze prepared from the following raw materials in parts by weight: 33 parts potassium mineral, 26 parts of kaolin, 16 parts quartz sand, 10 parts of aluminum borate whiskers modified, spodumene 7 parts, 6 parts of a lubricant , 2 parts of calcium silicate.

[0034] In order potassium mineral, kaolin based material of the formula system, by adding a lubricant, oily feel can be obtained, fine, white jade having similar slab-like tactile sensation.

[0035] The potassium minerals illite, feldspar, mica in a weight ratio of 5: 3: 2.

[0036] Taking the above described mineral potassium can be improved in wear resistance to some extent, as compared to a single K-feldspar, can be more significantly improve the wear resistance.

[0037] The method for preparing the modified aluminum borat...

Embodiment 2

[0049] White jade slab having a tactile, from bottom to top comprises a body layer, a glaze layer, the glaze layer is formed by applying the glaze by sintering suet on the body layer.

[0050] The suet glaze prepared from the following raw materials in parts by weight: 34 parts potassium mineral, 28 parts of kaolin, 20 parts of quartz sand, 6 parts of the modified aluminum borate whiskers, spodumene 8 parts, 3 parts of a lubricant , 1 part of calcium silicate.

[0051] The potassium minerals illite, feldspar, mica weight ratio of 2: 2: 1 composition.

[0052] The method for preparing the modified aluminum borate whiskers:

[0053] Sl, the grass 3 parts by weight of sodium, 2 parts by weight of sodium ligninsulfonate, 4 parts by weight of glycerol were added to 30.8 parts by weight of deionized water to prepare a mixed solution, and then 10 parts by weight of aluminum borate whiskers were added to the mixed solution , stir speed to 800rpm, further added 0.2 parts by weight of triet...

Embodiment 3

[0062] White jade slab having a tactile, from bottom to top comprises a body layer, a glaze layer, the glaze layer is formed by applying the glaze by sintering suet on the body layer.

[0063] The suet glaze prepared from the following raw materials in parts by weight: 31 parts potassium mineral, 30 parts of kaolin, 15 parts of quartz sand, 9 parts of the modified aluminum borate whiskers, spodumene 6 parts, 5 parts of lubricant , 4 parts of calcium silicate.

[0064] The potassium minerals illite, feldspar, mica in a weight ratio of 6: 3: 1 composition.

[0065] The method for preparing the modified aluminum borate whiskers:

[0066] Sl, 2 parts by weight of the sodium oxalate, 1.5 parts by weight of sodium ligninsulfonate, 2.5 parts by weight of glycerol were added to 33.7 parts by weight of deionized water to prepare a mixed solution, and then 10 parts by weight of aluminum borate whiskers were added to the mixed solution , stir speed to 500rpm, further added 0.3 parts by weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com