Method for manufacturing aluminum borate crystal whisker enhancement combustor throat embedded ring inner-cooling aluminum piston

A technology of aluminum borate whisker and manufacturing method, which is applied in the field of aluminum borate whisker-enhanced combustion chamber throat inlaid inner cooling aluminum piston manufacturing, which can solve the problems of inability to realize soluble core positioning, unrealized process, etc., and achieve good casting Manufacturability, improved thermal fatigue performance, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

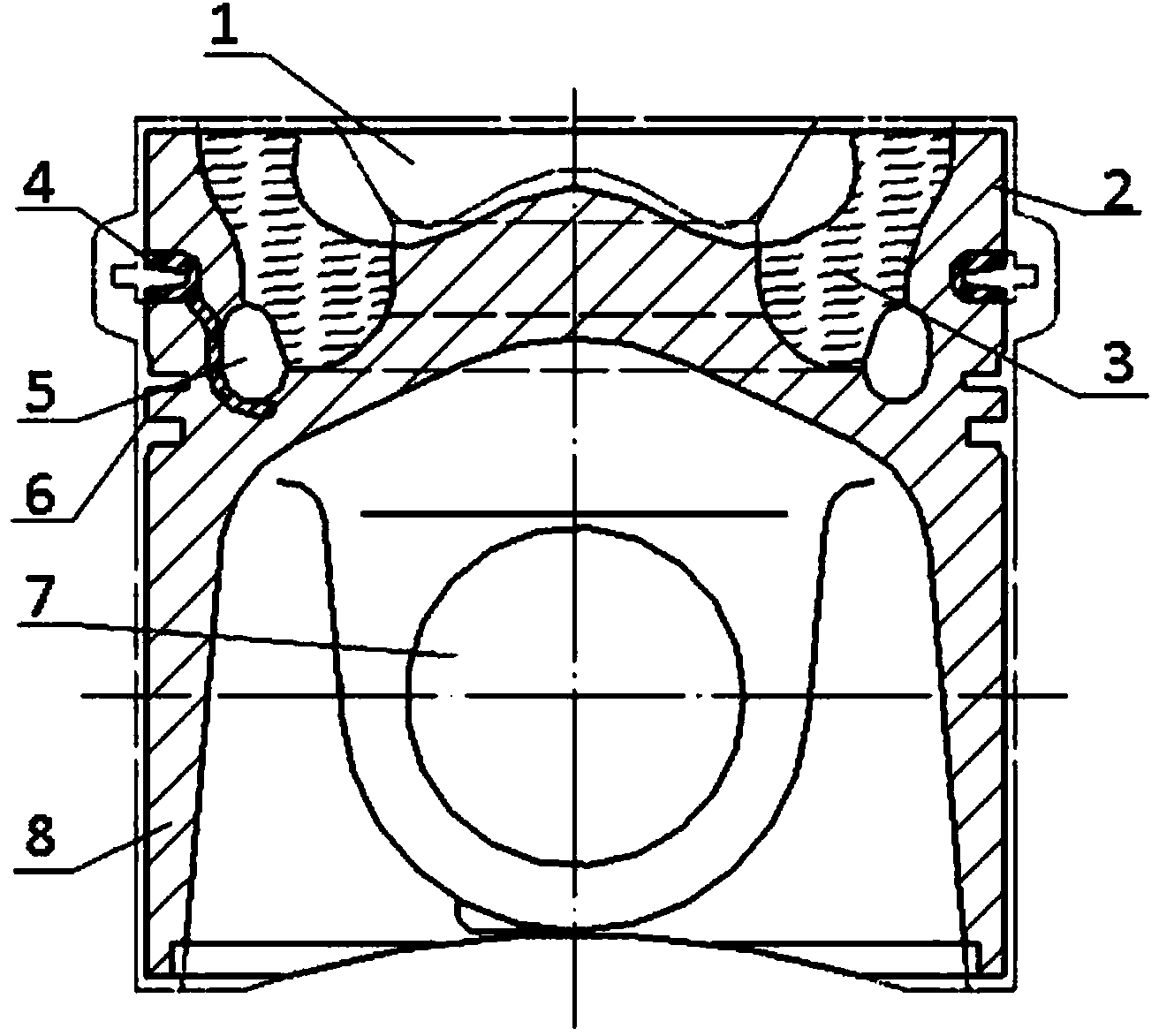

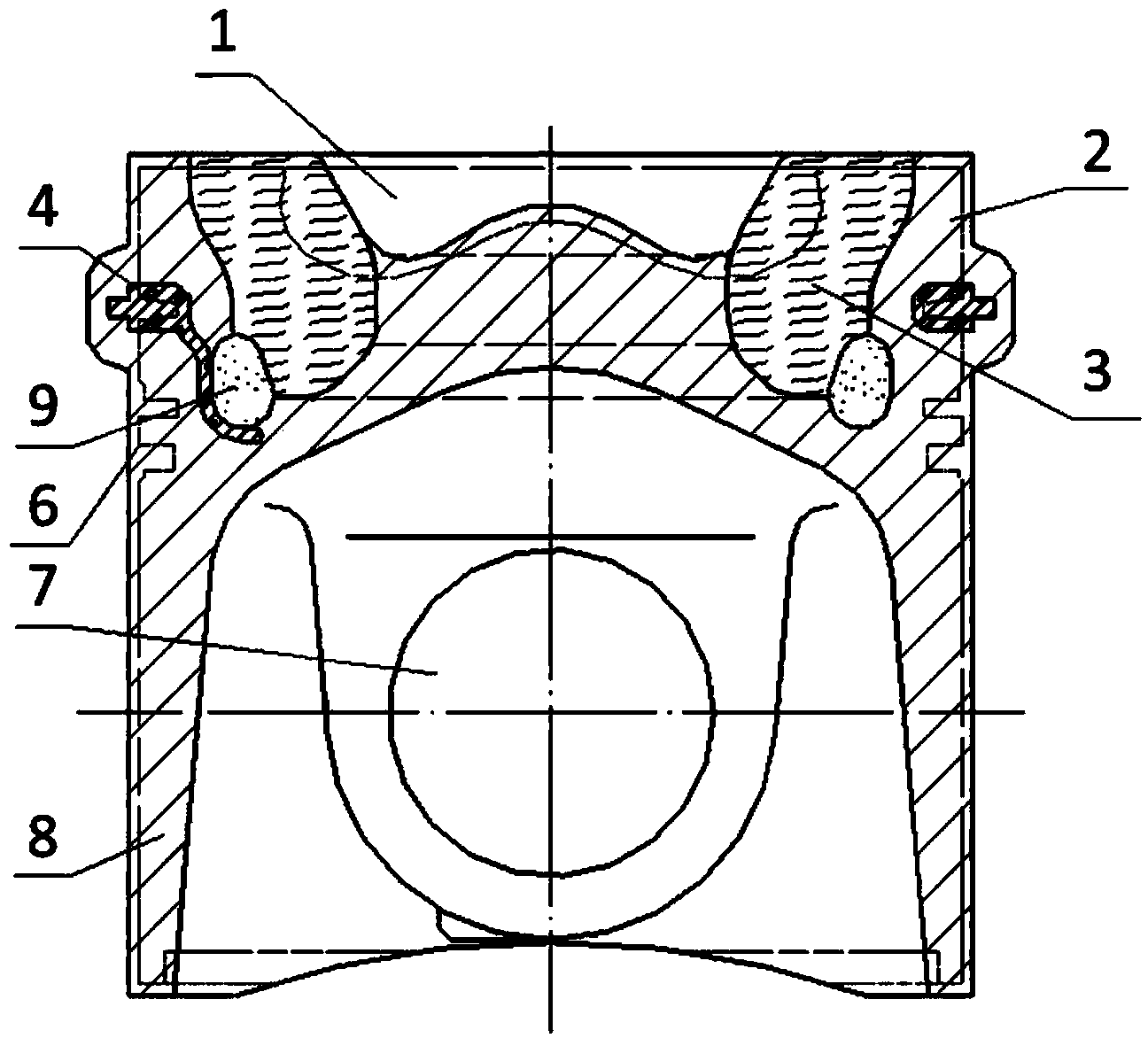

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0033] A method for manufacturing an aluminum borate whisker-enhanced combustion chamber throat-inlaid inner-cooled aluminum piston, which uses an in-situ growth method to manufacture an aluminum borate whisker prefabricated blank, which is then processed by liquid die forging to cast the piston blank and machined it For the finished product of the piston, the specific steps are:

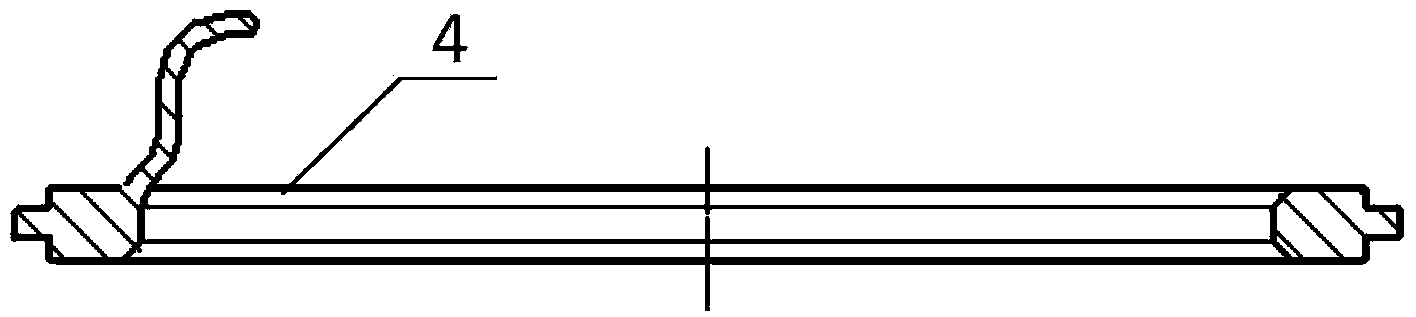

[0034] 1). The aluminum borate whisker preform blank is manufactured by in-situ growth method. The shape of the blank is basically close to the final shape, leaving only 1-3mm machining allowance; the volume fraction of the aluminum borate whisker preform is high, and the volume fraction can reach 20-50%, the strength of the prefabricated part is greater than that of the alumina fiber prefabricated part, and the ceramic salt core can be fixed in the casting mold by cooperatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com