Heat treatment process for recovering endurance property of notch of welding assembly of GH4169 alloy forge piece

A technology of GH4169 and welding components, which is applied in the field of heat treatment, can solve the problems of persistent notch sensitivity, less δ phase content, notch sensitivity, etc., and achieve the effect of eliminating notch sensitivity and improving the manufacturing qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Taking GH4169 alloy forging as an example to specifically illustrate the implementation process of the present invention.

[0019] 1) Intermediate heat treatment

[0020] Put the notch-sensitive GH4169 alloy welded assembly into an air furnace, heat it to 950°C, keep it warm for 2h, and cool it to room temperature within 0.5h.

[0021] 2) aging treatment

[0022] Put the GH4169 alloy welding assembly that has undergone intermediate heat treatment into an air furnace, heat it to 700°C, keep it for 8h, cool it to 600°C at a rate of 50±10°C / h, keep it for 8h, and air cool.

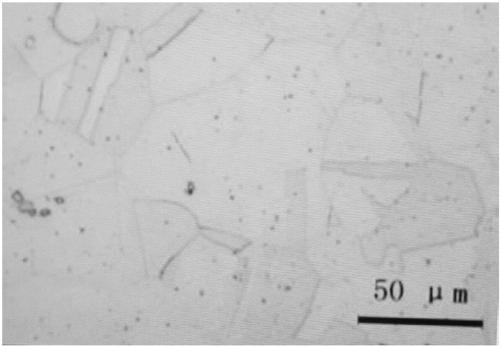

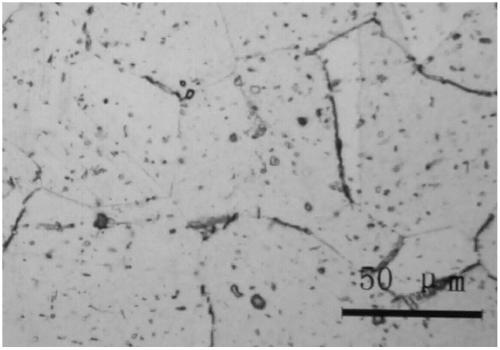

[0023] Alloy structure before and after heat treatment figure 1 , 2 It can be seen from the figure that the notch sensitivity of the GH4169 alloy welded assembly can be eliminated by using this method.

Embodiment 2

[0025] 1) Intermediate heat treatment

[0026] Put the notch-sensitive GH4169 alloy welding assembly into an air furnace, heat it to 980°C, keep it warm for 0.5h, and cool it to room temperature within 0.5h.

[0027] 2) aging treatment

[0028] Put the GH4169 alloy welded assembly that has undergone intermediate heat treatment into an air furnace, heat it to 800°C, keep it for 8h, cool it to 700°C at a rate of 50±10°C / h, keep it for 8h, and air cool.

[0029] Using this method eliminates the notch sensitivity of the GH4169 alloy welded assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com