Ceramic-metal composite material mixed multilayer material

A technology of composite materials and multilayer materials, which is applied in the field of ceramic-metal-composite hybrid multilayer materials, can solve the problems of low oxidation resistance, low strength and hardness, limited application fields, and easy oxidation, etc., to achieve notch sensitivity Reduce, increase strength and toughness, improve the effect of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

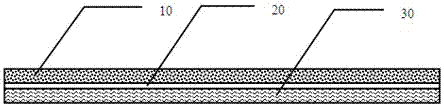

[0012] A ceramic-metal-composite hybrid multilayer material is characterized in that it is composed of C / SiC material, metal sheet and Glare laminate, and its structure is a laminated structure, from top to bottom followed by C / SiC material, metal sheet and Glare laminates. The thickness of the C / SiC material is 2 mm. The metal sheet is Mo metal material with a thickness of 0.4mm. The thickness of the Glare laminate is 3mm.

Embodiment 2

[0014] A ceramic-metal-composite hybrid multilayer material is characterized in that it is composed of C / SiC material, metal sheet and Glare laminate, and its structure is a laminated structure, from top to bottom followed by C / SiC material, metal sheet and Glare laminates. The thickness of the C / SiC material is 3 mm. The metal sheet is Ti metal material with a thickness of 0.3mm. The thickness of the Glare laminate is 4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com