Selective laser melting forming Inconel718 alloy and heat treatment method thereof

A technology of laser selective melting and heat treatment, which is applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the problems of unfavorable Nb element release, reduction of precipitation strengthening phase, low solid solution temperature, etc., and achieve good comprehensiveness Effects of improving mechanical properties, room temperature yield strength, and room temperature tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The invention discloses a heat treatment method for improving the performance of Inconel718 alloy formed by laser selective melting, which can be realized through the following process steps:

[0035] Step (1): The Inconel718 sample formed by selective laser melting is subjected to high-temperature hot isostatic pressing heat treatment, and then air is quickly cooled to room temperature;

[0036] The specific process parameters of this step: the heat treatment temperature of hot isostatic pressing is 1050°C-1120°C, the pressure is 1400bar-1480bar, and the holding time is 90min-120min;

[0037] Process parameters of this embodiment: the temperature is 1080°C, the pressure is 1480 bar, and the holding time is 120 min.

[0038] Among them, the heating rate of the hot isostatic pressing equipment is 7°C / min to 8°C / min, and the pressure increase rate is 10bar / min to 11bar / min; the optimal process parameters are set as follows: the temperature increase rate is 8°C / min, The s...

Embodiment 2

[0046] This embodiment is the same as Embodiment 1 except for the following features.

[0047] During the heat treatment in step (2) and step (3), the heating rate of the furnace is the same, that is, 5°C / min to 6°C / min; both are preferably 6°C / min.

[0048] Combine below Figure 1 to Figure 3 , the Inconel718 alloy obtained in the above embodiments of the present invention and its performance improvement will be further described.

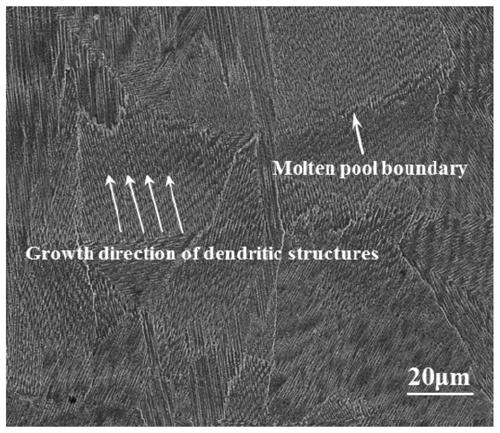

[0049] figure 1 It is a 2000 times enlarged microstructure diagram of the sample of the present invention before heat treatment.

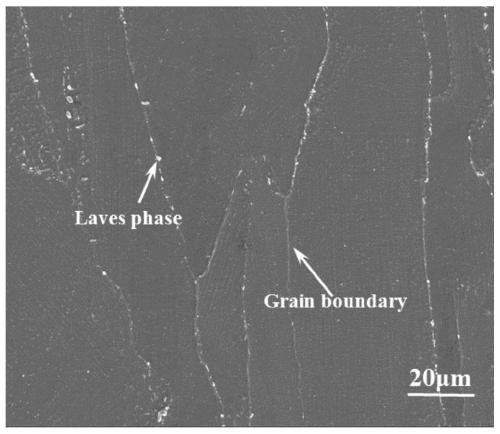

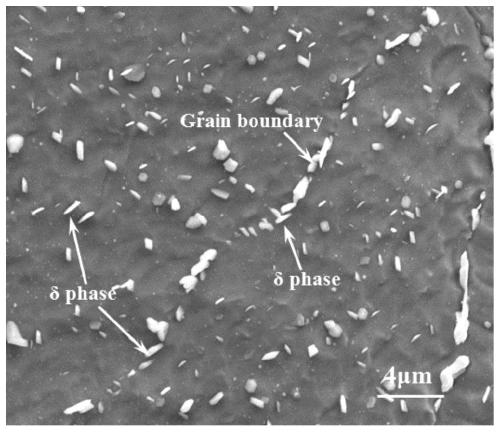

[0050] figure 1 It shows the structure of the samples observed by scanning electron microscope after being ground and polished and corroded by corrosive solution. It can be seen that there are obvious overlapping boundaries in the alloy before heat treatment, and there are a large number of dendritic subgrain structures in the arc-shaped molten pool and on the overlapping boundaries, and the white precipitates betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature tensile strength | aaaaa | aaaaa |

| Room temperature yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com