Anti-scratching mandrel material

An anti-scratch and mandrel technology, which is applied in the field of mandrel materials with improved impact resistance and anti-scratch mandrel materials, can solve the problems of mandrel scratches, scratches and scrapping, etc., to reduce element content and reduce carbonization Effect of improving object size and impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

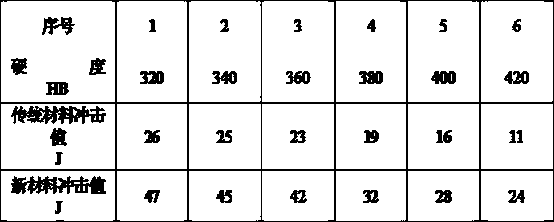

Examples

Embodiment 1

[0020] An anti-scratch mandrel material, the formula ratio is as follows by weight percentage: C 0.28%, Si 0.4%, Mn 0.2%, S≤0.003%, P≤0.012%, Cr 4%, Mo: 1.1%, V 0.6 %, Ni 0.2%, and the rest is Fe.

[0021] The preparation method of the anti-scratch mandrel material is as follows:

[0022] (1) Electric furnace smelting: The furnace charge is composed of steel return, pig iron, carbon steel return and scrap steel.

[0023] (2) Dephosphorization by slagging: add lime at the bottom of the electric furnace before loading the charge to facilitate the formation of molten slag in advance for dephosphorization. After all the charge is melted, add fluorite and lime to create molten slag with good fluidity. Gradually add ore to facilitate dephosphorization. In order to achieve the purpose of dephosphorization, slag flow operation or full slag removal operation can be used. The phosphorus in electric furnace tapping must be less than 0.005% to ensure that the finished product phosphorus ...

Embodiment 2

[0034] An anti-scratch mandrel material, the formula ratio is as follows by weight percentage: C 0.35%, Si 0.8%, Mn 0.6%, S≤0.003%, P≤0.012%, Cr 5%, Mo: 1.3%, V 0.8 %, Ni 0.5%, and the rest is Fe.

[0035] The preparation method of the anti-scratch mandrel material is as follows:

[0036] (1) Electric furnace smelting: The furnace charge is composed of steel return, pig iron, carbon steel return and scrap steel.

[0037] (2) Dephosphorization by slagging: add lime at the bottom of the electric furnace before loading the charge to facilitate the formation of molten slag in advance for dephosphorization. After all the charge is melted, add fluorite and lime to create molten slag with good fluidity. Gradually add ore to facilitate dephosphorization. In order to achieve the purpose of dephosphorization, slag flow operation or full slag removal operation can be used. The phosphorus in electric furnace tapping must be less than 0.005% to ensure that the finished product phosphorus ...

Embodiment 3

[0048] An anti-scratch mandrel material, the formula ratio is as follows by weight percentage: C 0.32%, Si 0.6%, Mn 0.4%, S≤0.003%, P≤0.012%, Cr 4.5%, Mo: 1.2%, V 0.7%, Ni 0.4%, and the rest is Fe.

[0049] The preparation method of the anti-scratch mandrel material is as follows:

[0050] (1) Electric furnace smelting: The furnace charge is composed of steel return, pig iron, carbon steel return and scrap steel.

[0051] (2) Dephosphorization by slagging: add lime at the bottom of the electric furnace before loading the charge to facilitate the formation of molten slag in advance for dephosphorization. After all the charge is melted, add fluorite and lime to create molten slag with good fluidity. Gradually add ore to facilitate dephosphorization. In order to achieve the purpose of dephosphorization, slag flow operation or full slag removal operation can be used. The phosphorus in electric furnace tapping must be less than 0.005% to ensure that the finished product phosphorus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com