Treatment method for enhancing thermal fatigue property of forged Ni-Cr-Co based alloy

A processing method and a technology of base alloys, which are applied in the field of high-temperature alloy structural materials, can solve problems such as blank thermal fatigue performance of nickel-base superalloys, achieve great application value, improve thermal fatigue performance, and improve the effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

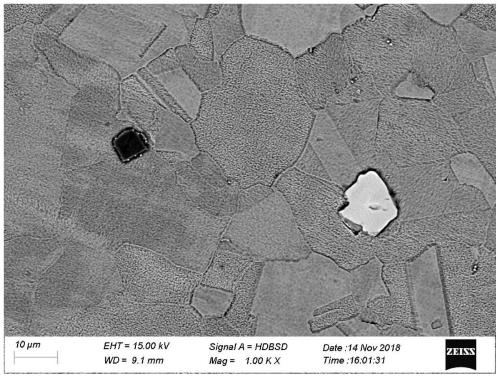

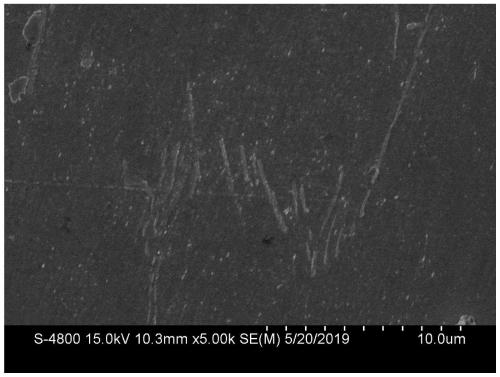

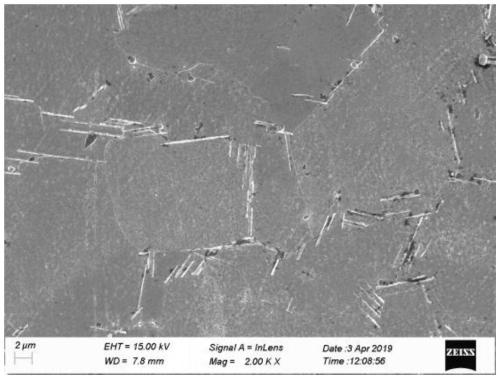

Image

Examples

Embodiment 1

[0035] Preparation before processing: Cut the forged Ni-Cr-Co-based alloy into a cylindrical alloy sample with a diameter of 8mm and a height of 5mm by wire cutting machine, then ultrasonically clean it in alcohol for 10min, and dry it for use; the corundum crucible Put it at 700°C for 3 hours to dehumidify and set aside.

[0036] 1) High-temperature homogenization treatment: raise the temperature of the box-type furnace to 1250 ° C, and after the temperature is stable, put the crucible containing the alloy sample into the uniform temperature zone of the box-type furnace, and pass in argon gas for gas protection; alloy test The sample was kept in a box furnace for 9 hours, the gas protection was stopped, and it was air-cooled to room temperature after being released from the furnace;

[0037] 2) Pre-solution treatment: raise the temperature of the box furnace to 870 ° C, and after the temperature is stable, put the crucible containing the alloy sample that has been subjected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com