High-temperature thermal barrier coating material

A coating material, warm technology, applied in the field of materials science and engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

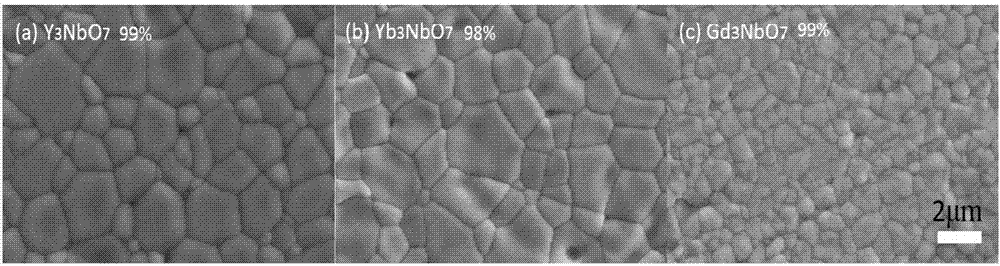

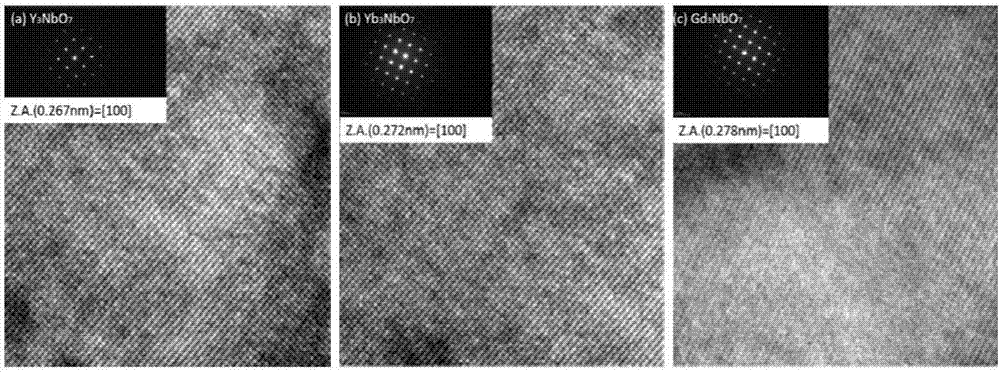

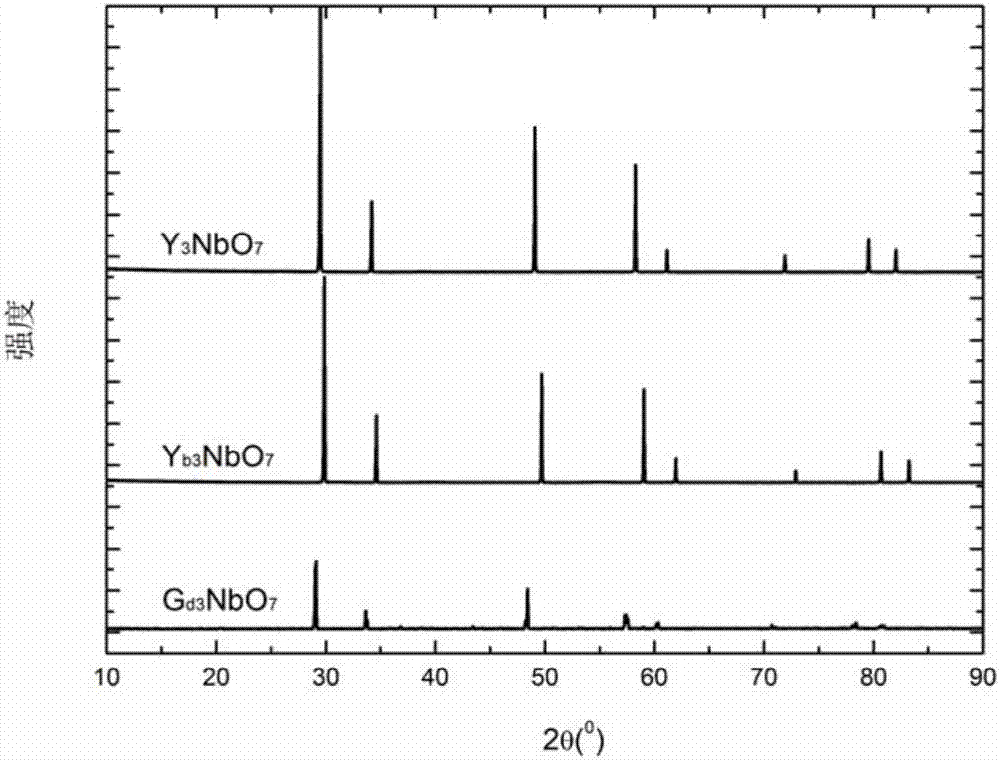

[0026] Embodiment 1: Preparation Y 3 NbO 7 Thermal Barrier Coating Materials

[0027] Utilize the aforementioned solid-phase method to prepare Y 3 NbO 7 The powder is sprayed granulated and dried to make a high-fluidity powder with a particle size of 30-70 microns. A layer of CoCrAlY alloy with a thickness of about 250 microns is deposited on the surface of the cobalt-based superalloy by electron beam physical vapor deposition technology. The junction layer, and then deposit Y with a thickness of about 300 microns on its surface by APS method 3 NbO 7 Ceramic coating, coating system structure such as Figure 6 shown. After testing, the porosity of the coating is ~11%, the thermal conductivity of the coating is 0.48W / m·K at 1000°C, and the phase structure remains stable from room temperature to 1600°C.

Embodiment 2

[0028] Embodiment 2: Preparation of Yb 3 NbO 7 thermal barrier coating

[0029] Utilize the aforementioned solid-phase method to prepare Yb 3 NbO 7 The powder is sprayed granulated and dried to make a high-fluidity powder with a particle size of 30-70 microns. A layer of NiCrAlY alloy with a thickness of about 250 microns is deposited on the surface of the nickel-based superalloy by electron beam physical vapor deposition technology. Junction layer, and then deposit Yb with a thickness of about 300 microns on its surface by APS method 3 NbO 7 Ceramic coating, coating system structure such as Figure 7 shown. After testing, the porosity of the coating is ~10%, the thermal conductivity of the coating is 0.41W / m·K at 1000°C, and the phase structure remains stable from room temperature to 1600°C.

Embodiment 3

[0030] Embodiment 3: preparation Gd 3 NbO 7 thermal barrier coating

[0031] Gd was prepared by the aforementioned solid-phase method 3 NbO 7 The powder is sprayed granulated and dried to make a high-fluidity powder with a particle size of 30-70 microns. A layer of FeCrAlY alloy with a thickness of about 150 microns is deposited on the surface of the nickel-based superalloy by electron beam physical vapor deposition technology. The junction layer, and then deposit Gd with a thickness of about 200 microns on its surface by APS method 3 NbO 7 ceramic coating. The structure of the coating system is as Figure 8 As shown, the porosity of the coating is ~10%, the thermal conductivity of the coating is 0.46W / m·K at 1000°C, and the phase structure remains stable from room temperature to 1600°C. Embodiment 4: preparation (La 0.7 Y 0.3 ) 3 NbO 7 thermal barrier coating

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com