Method for preparing antibacterial edible films

An antibacterial and edible technology, which is applied in the field of preparation of edible films, can solve the problems of insufficient antibacterial ability and off-white color, and achieve the effect of good film-forming effect, off-white color and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

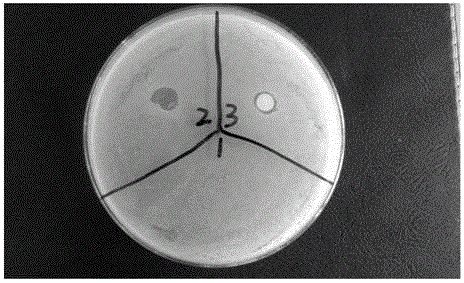

Embodiment 1

[0041] The stirring ball mill is used as the reaction device, and the ball milling reaction is carried out by mechanical solid-phase activation method. Pullulan and ε-polylysine are used as raw materials, and the mass ratio is 5:1.5. The mechanical activation time is 5 minutes and the temperature is 25°C. 1. The stirring speed is 415r / min, and the grinding medium is a stainless steel grinding ball of φ5-10mm to prepare the pullulan and ε-polylysine complex. The film-forming solution is prepared according to the ratio that the mass concentration of the compound of pullulan and ε-polylysine is 2g / 100mL, the mass concentration of gelatin is 5g / 100mL, and the mass concentration of glycerin is 1g / 100mL: Dissolve gelatin in distilled water at 80-90°C, cool to 50-60°C, add pullulan and ε-polylysine complex to dissolve, add glycerin after cooling to room temperature, stir evenly, and magnetically stir for 10 minutes. The resulting film-forming solution is poured into a polypropylene p...

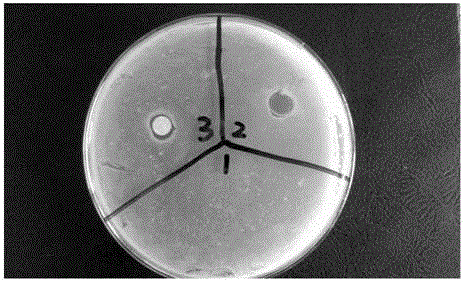

Embodiment 2

[0043] The stirring ball mill is used as the reaction device, and the ball milling reaction is carried out by mechanical solid-phase activation method. Chitosan and ε-polylysine are used as raw materials. The mass ratio is 5:1.8. The mechanical activation time is 10 minutes, and the temperature is 25 ° C The stirring speed was 415r / min, and the complex of chitosan and ε-polylysine was prepared. According to the mass concentration of the complex of chitosan and ε-polylysine is 2g / 100mL, the mass concentration of gelatin is 5g / 100mL, and the mass concentration of glycerin is the ratio of 2g / 100mL to prepare the film-forming solution: first gelatin Dissolve in distilled water at 80-90°C, cool to 50-60°C, add chitosan and ε-polylysine complex to dissolve, add glycerin after cooling to room temperature, stir evenly, and magnetically stir for 10 minutes. The film-forming solution is poured into a polypropylene petri dish, placed at room temperature to form a film for 8-10 hours, and...

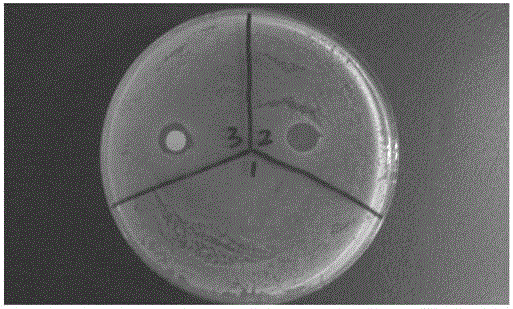

Embodiment 3

[0045] The stirring ball mill was used as the reaction device, and the ball milling reaction was carried out by mechanical solid-phase activation method. Dextran and ε-polylysine were used as raw materials, and the mass ratio was 5:2. The mechanical activation time was 8 minutes, and the temperature was 25°C. The stirring speed was 415 r / min, and the compound of dextran and ε-polylysine was prepared. According to the mass concentration of the compound of dextran and ε-polylysine is 3g / 100mL, the mass concentration of gelatin is 5g / 100mL, and the mass concentration of glycerin is 1g / 100mL to prepare the film-forming solution: first gelatin Dissolve in distilled water at 80-90°C, cool to 50-60°C, add the esterified compound of dextran and ε-polylysine to dissolve, add glycerin after cooling to room temperature, stir evenly, and magnetically stir for 10 minutes. The film-forming solution is poured into a polypropylene petri dish, placed at room temperature to form a film for 8-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com