Electroluminescent display panel and packaging method thereof as well as display device

An electroluminescence display and panel technology, which is applied in the direction of circuits, electrical components, and electric solid devices, can solve the problems of water blocking and oxygen blocking performance reduction, and achieve the effect of improving water blocking and oxygen blocking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

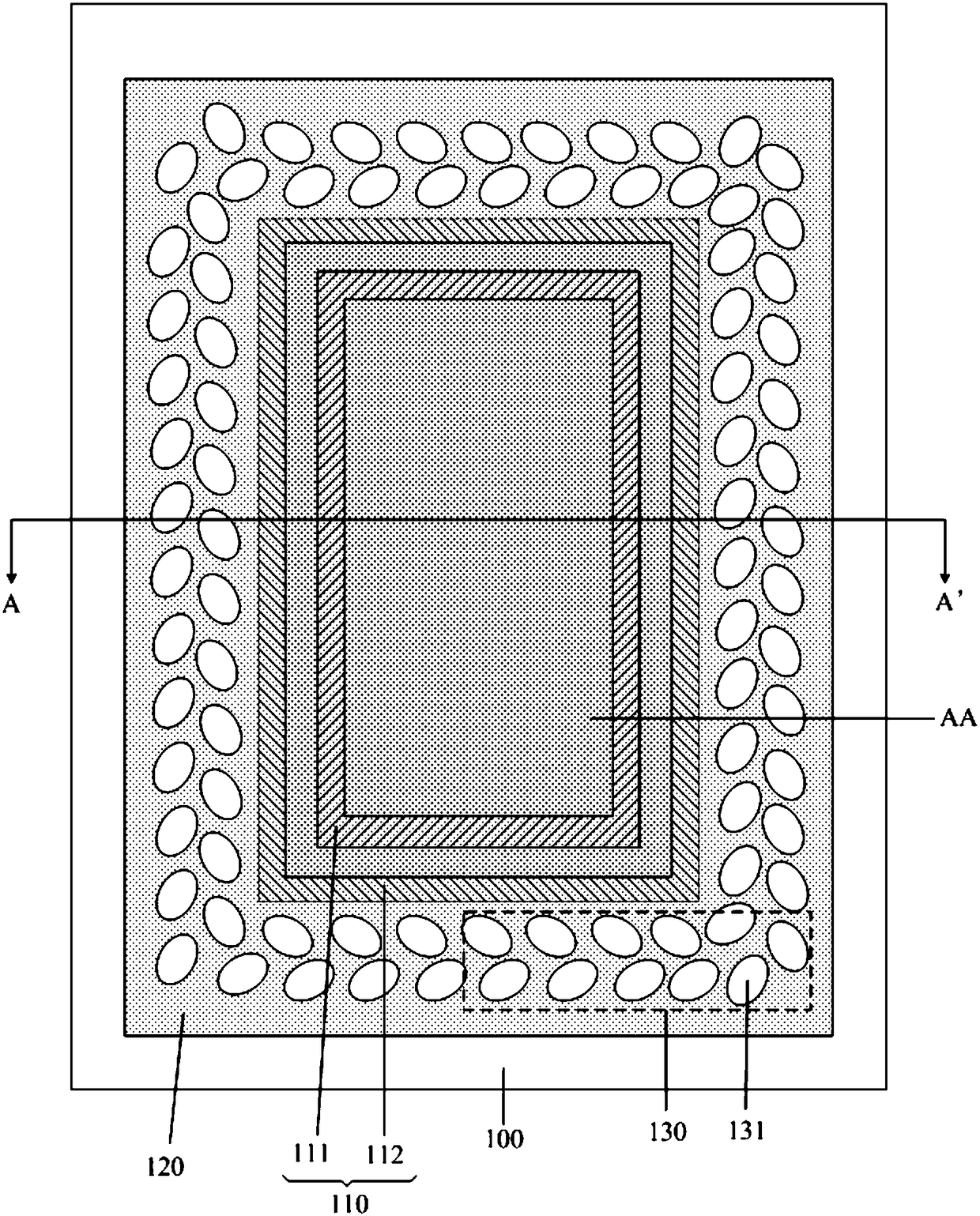

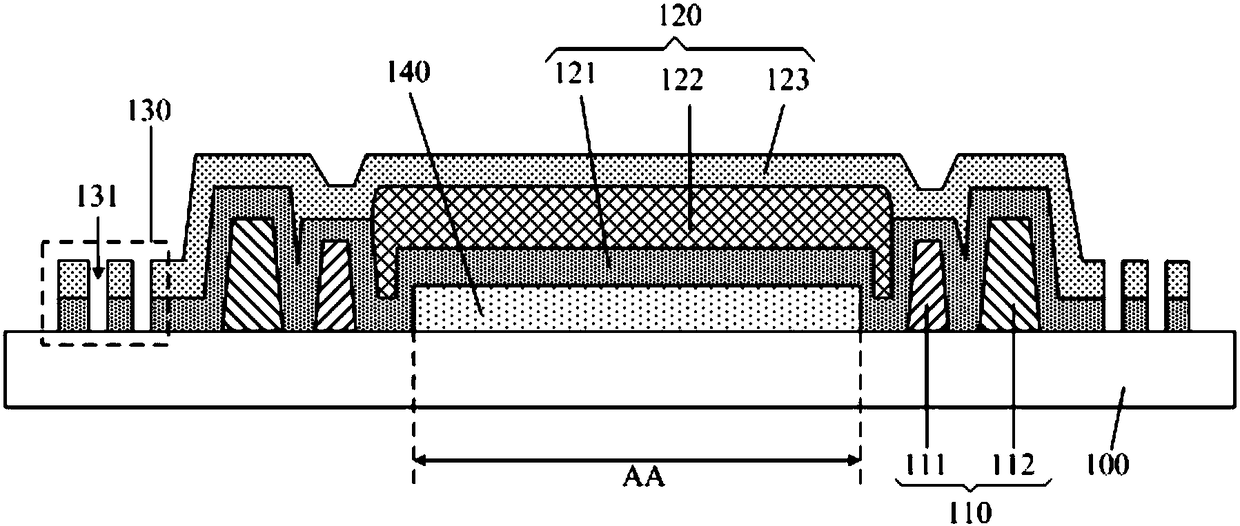

Embodiment 1

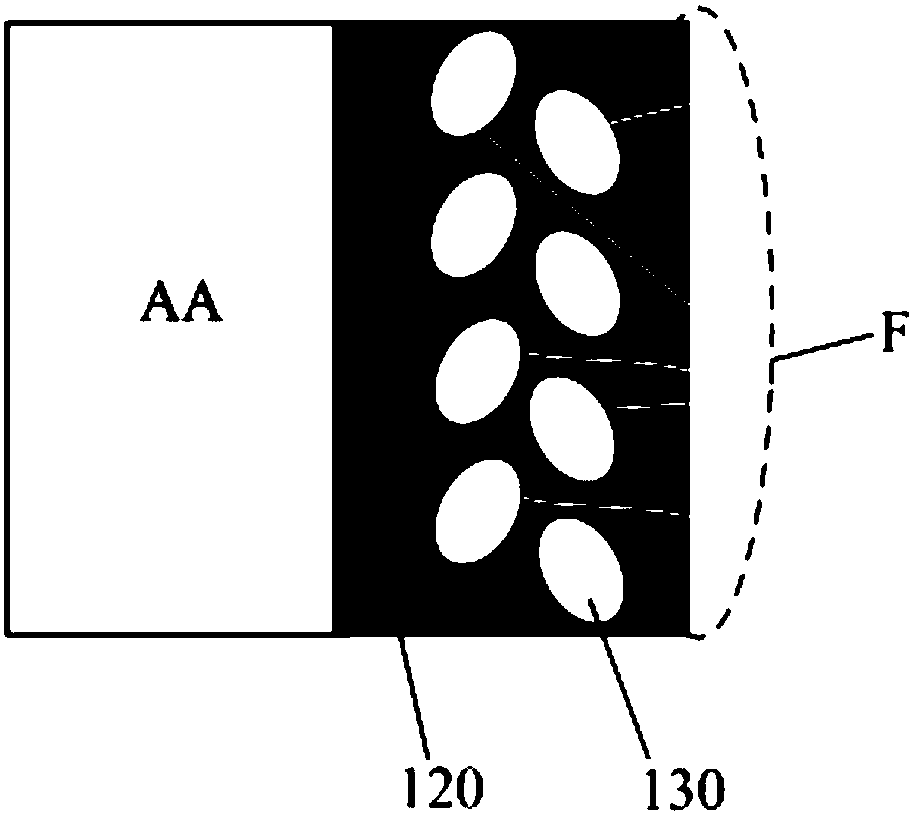

[0055] In specific implementation, in the above-mentioned packaging method provided by the embodiment of the present invention, the packaging film covering the display area, the barrier wall and the peripheral area of the barrier wall is formed, which may specifically include:

[0056] An encapsulation film with a hollow structure covering the display area, the retaining wall and the peripheral area of the retaining wall is formed by using an evaporation process under the shield of the mask plate. In this way, excessive patterning process can be avoided, and the process preparation process can be reduced.

[0057] Specifically, the following steps may be included:

[0058] (1) Forming a first inorganic encapsulation layer with a hollow structure covering the display area, the retaining wall, and the peripheral area of the retaining wall by using an evaporation process under the shielding of the first mask. Wherein, the shielding area of the first mask plate correspond...

Embodiment 2

[0062] In specific implementation, in the above-mentioned packaging method provided by the embodiment of the present invention, the packaging film covering the display area, the barrier wall and the peripheral area of the barrier wall is formed, which may specifically include:

[0063] A patterning process is used to form an encapsulation film covering the display area, the retaining wall and the peripheral area of the retaining wall;

[0064] A photolithography process is used to form a hollow structure in a part of the peripheral area of the barrier wall by the encapsulation film.

[0065] Specifically, the following steps may be included:

[0066] (1) A first inorganic encapsulation layer is formed on the array substrate on which the barrier walls are formed by using one patterning process. Wherein, the formed first inorganic encapsulation layer covers the display area, the barrier wall and the peripheral area of the barrier wall.

[0067] (2) An organic encapsula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com