Non-thermal processing method for soft fruit and vegetable cans

A non-thermal processing and soft canning technology, which is applied in the fields of fruit and vegetable preservation, heating preservation of fruits/vegetables, sugar preservation of fruits/vegetables, etc. It can solve the problems of loss of quality and nutrients, loss of color, aroma and taste of fruits and vegetables, etc. Achieve the effect of uniform pulp texture, increased pulp hardness, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

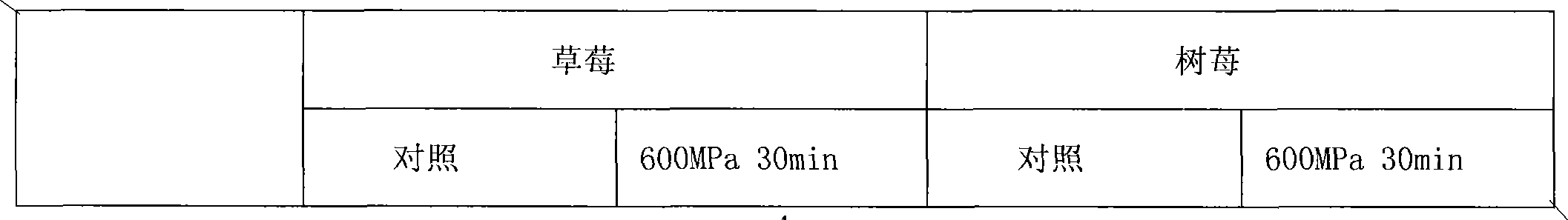

[0024] The processing of embodiment 1 strawberry / raspberry soft can

[0025] (1) Grading and cleaning of material selection: select fresh, complete fruit, uniform size, bright red color, eight mature strawberries / raspberries as raw materials, divide them into two grades of size, rinse with flowing water, remove the sediment on the surface of the fruit, dirt etc.

[0026] (2) Remove the calyx: remove the calyx and fruit stem of the strawberry / raspberry.

[0027] (3) Blanching: Blanch the cut strawberries / raspberries with steam for 1 min.

[0028] (4) Cooling: Put the blanched strawberries / raspberries into an ice-water bath to cool to room temperature immediately.

[0029] (5) Canning and adding sugar solution: put strawberries / raspberries into the EVOH bag, and add a certain amount of sugar solution,

[0030] Wherein the volume ratio of strawberry / raspberry to sugar liquid is 60:40, and the concentration of sugar liquid is 20wt%.

[0031] (6) The EVOH bag that strawberry / ra...

Embodiment 2

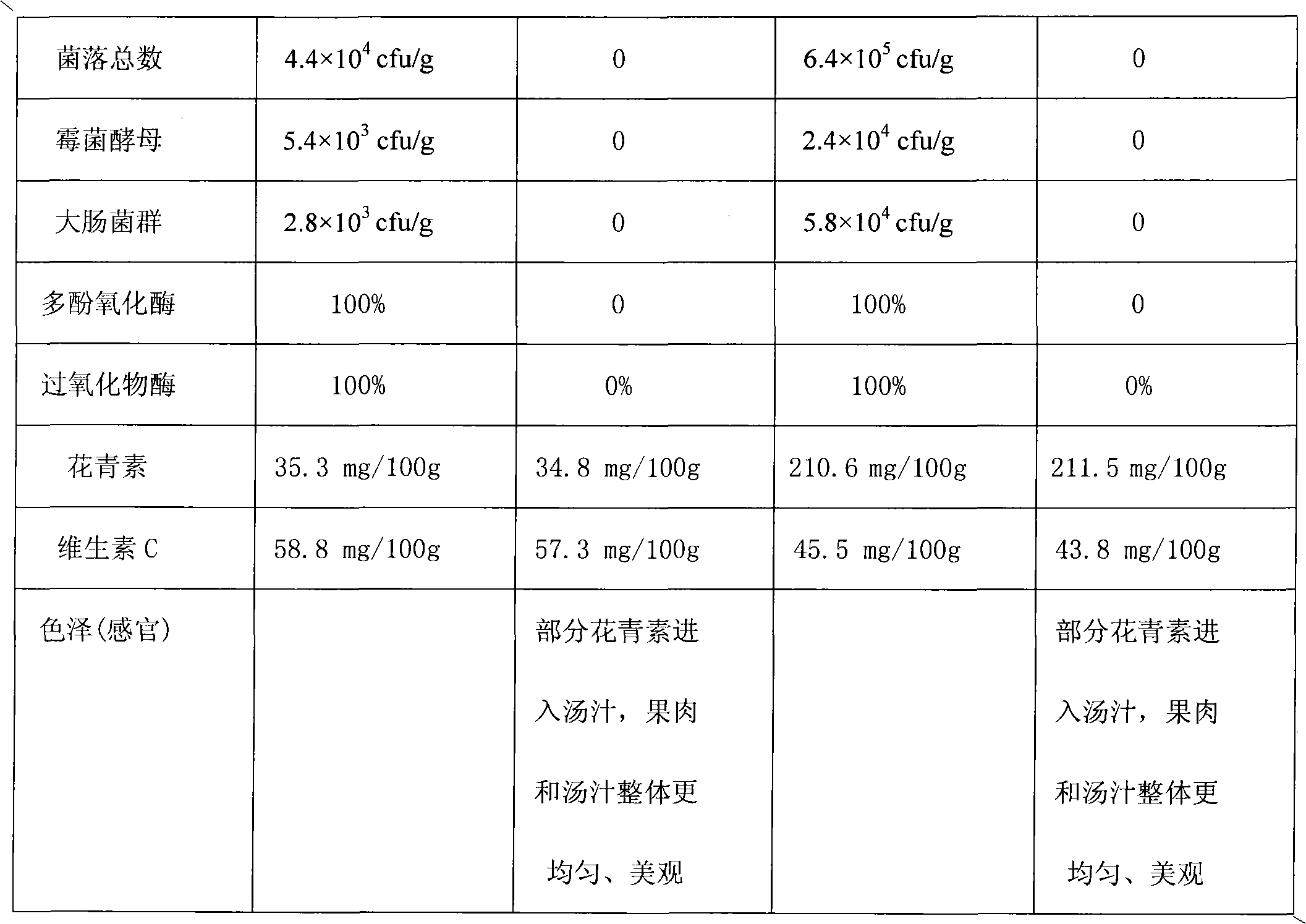

[0039] The processing of embodiment 2 potato / yam soft can

[0040] (1) Material selection and graded cleaning: select fresh raw materials, rinse with flowing water, and remove surface sediment, dirt, etc.

[0041] (2) Slicing: Cut the potato / yam into slices or cubes of the same size.

[0042] (3) Preserve the crispness: the cut potatoes / yams are put into 0.05wt% CaCl 2 Soak in water for 10 minutes, then rinse in clean water.

[0043] (4) Blanching: Potatoes / yams are blanched with steam for 1 min.

[0044] (5) Cooling: Put the blanched potatoes / yams into an ice-water bath to cool to room temperature immediately.

[0045] (6) Canning and adding salt water: adding potatoes / yams into PVPP cups or bags, and adding a certain amount of salt water (3wt%), the volume ratio of potatoes / yams to salt water is 70:30.

[0046] (7) Vacuumize the PVPP cup or bag containing the potato / yam, the vacuum degree is 60KPa, and the exhaust time is 10min; then vacuum seal it with EVOH sealing film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com