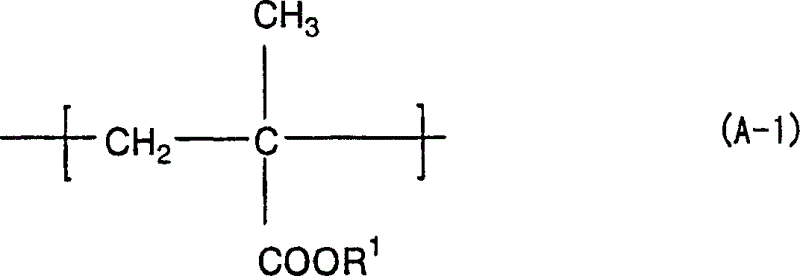

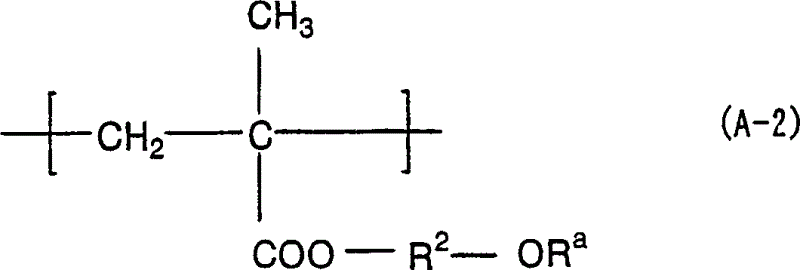

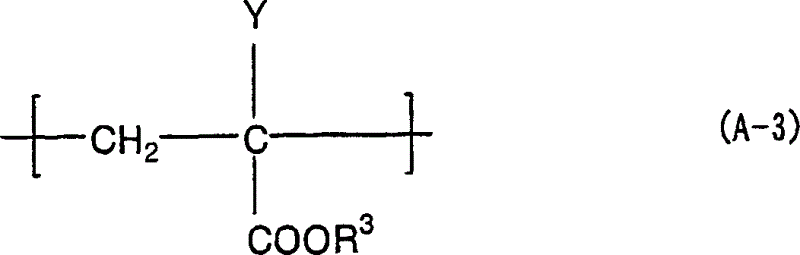

Acrylic resin composition, organosiloxane resin composition and laminate comprising the same

A technology of acrylic resin and organosiloxane, applied in the field of organosiloxane resin composition and organosiloxane polymer, can solve the problems of insufficient durability and coating cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0308] In the following examples, the obtained laminates were evaluated by the following methods. In addition, "part" and "%" in an Example mean "weight part" and "weight%".

[0309] (1) Paint storage stability: After storing the acrylic resin composition at 23° C. for 3 months, the state of the paint was visually observed, and the paint in which gelling was not observed was rated as good.

[0310] (2) Appearance evaluation: The appearance (presence or absence of foreign matters) of the coating layer of the test piece was visually tested, and the presence or absence of cracks was confirmed.

[0311] (3) Adhesion: (according to JIS K5400 standard) Adhesive adhesive tape (trade name "セロテ-プ") made by Nichiban (trade name "セロテ-プ") that is cut into 100 checkerboards at 1 mm intervals with scissors is adhered to the coating, and then vertically Tear with high force and evaluate the number of checkerboards left on the substrate.

[0312] (4) Scratch resistance: Scrub the test piece...

reference example 1

[0324] Reference example 1 (synthesis of acrylic resin (I))

[0325] In the flask equipped with reflux cooler and stirring device and replaced with nitrogen, add 90.1 parts of methyl methacrylate (hereinafter referred to as MMA), 13 parts of 2-hydroxyethyl methacrylate (hereinafter referred to as HEMA), 0.14 parts Parts of azobisisobutyronitrile (hereinafter referred to as AIBN) and 200 parts of 1,2-dimethoxyethane were dissolved. Then, the reaction was stirred at 70° C. for 6 h under nitrogen flow. The resulting reaction liquid was poured into n-hexane and purified by reprecipitation to obtain 81 parts of a copolymer (acrylic resin (I)) having an MMA / HEMA composition ratio of 90 / 10 (molar ratio). The hydroxyl value of this copolymer was 54.3 mg KOH / g, and the polystyrene-equivalent weight average molecular weight measured by gel permeation chromatography (GPC) (column: Shodex GPCA-804, eluent THF) was 180,000.

reference example 2

[0326] Reference example 2 (synthesis of acrylic resin (II))

[0327] Except having used 80.1 parts of MMA, 26 parts of HEMA, and 0.18 parts of AIBN, 85 parts of copolymers (acrylic resin (II)) having an MMA / HEMA composition ratio of 80 / 20 (molar ratio) were obtained in the same manner as in Reference Example 1. The hydroxyl value of this copolymer was 106.0 mg KOH / g, and the weight average molecular weight in terms of polystyrene was 80,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com