Primer and laminate including resin film formed from the primer

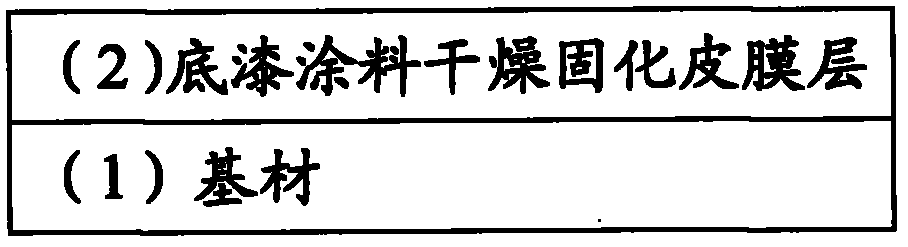

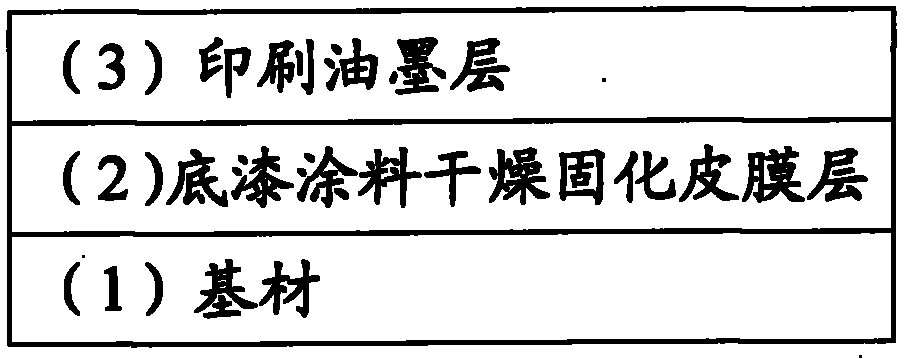

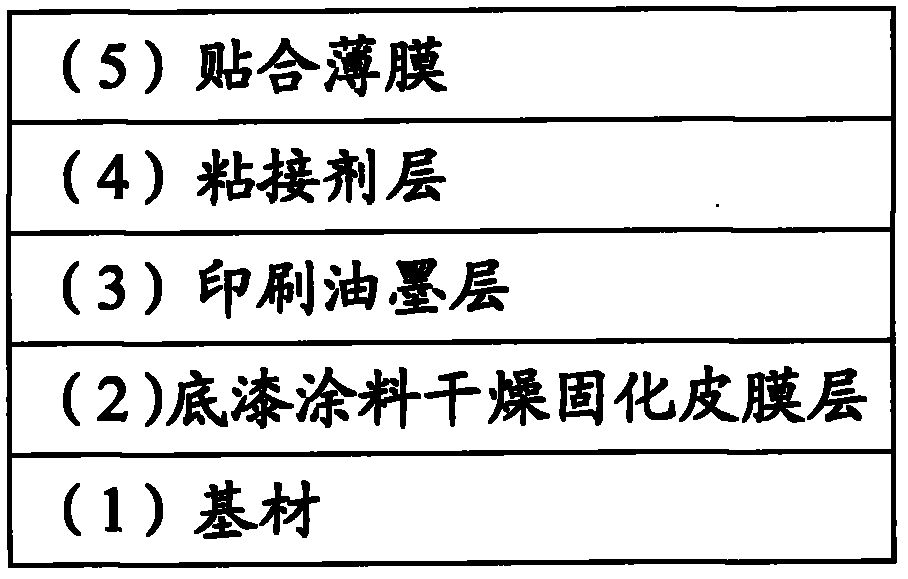

一种层叠体、底漆的技术,应用在合成树脂层状产品、涂层、底漆等方向,能够解决密合变差、基材与易粘接树脂层密合变差等问题,达到耐酸性优异、点再现性优异、密合性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Hereinafter, the present invention will be specifically described by way of examples and comparative examples.

[0102] (Preparation of Example Primers 1-7 and Comparative Example Primers 1-7)

[0103]The main ingredient solution (A) was prepared with the monomer compounding composition shown in Table 1 below. The solvent composition was adjusted to 70:14:6 of MEK, ethyl acetate, and propylene glycol monomethyl ether, and 10% of non-volatile components. Further, with the formula shown in Table 1, mixing the curing agent (B) and the compound (C) having two or more carboxylic acid groups or one or more carboxylic anhydride groups in one molecule, prepared Example primers 1 to 7, and compared Examples of primers 1-7.

[0104] [Table 1]

[0105]

[0106] In addition, the abbreviations in the table below are indicated as follows.

[0107] MMA: methyl methacrylate

[0108] AN: acrylonitrile

[0109] β-HEMA: β-hydroxyethyl methacrylate (the mark in the table omits β) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com