Hot water resistant polyamide thin layer and manufacturing method thereof

A polyamide film, hot water resistance technology, applied in chemical instruments and methods, polyurea/polyurethane coatings, synthetic resin layered products, etc., can solve the problem of insufficient adhesion between nylon film and ink, adhesives, peeling, etc. Problems, achieve excellent adhesion, excellent hot water resistance, and industrially beneficial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

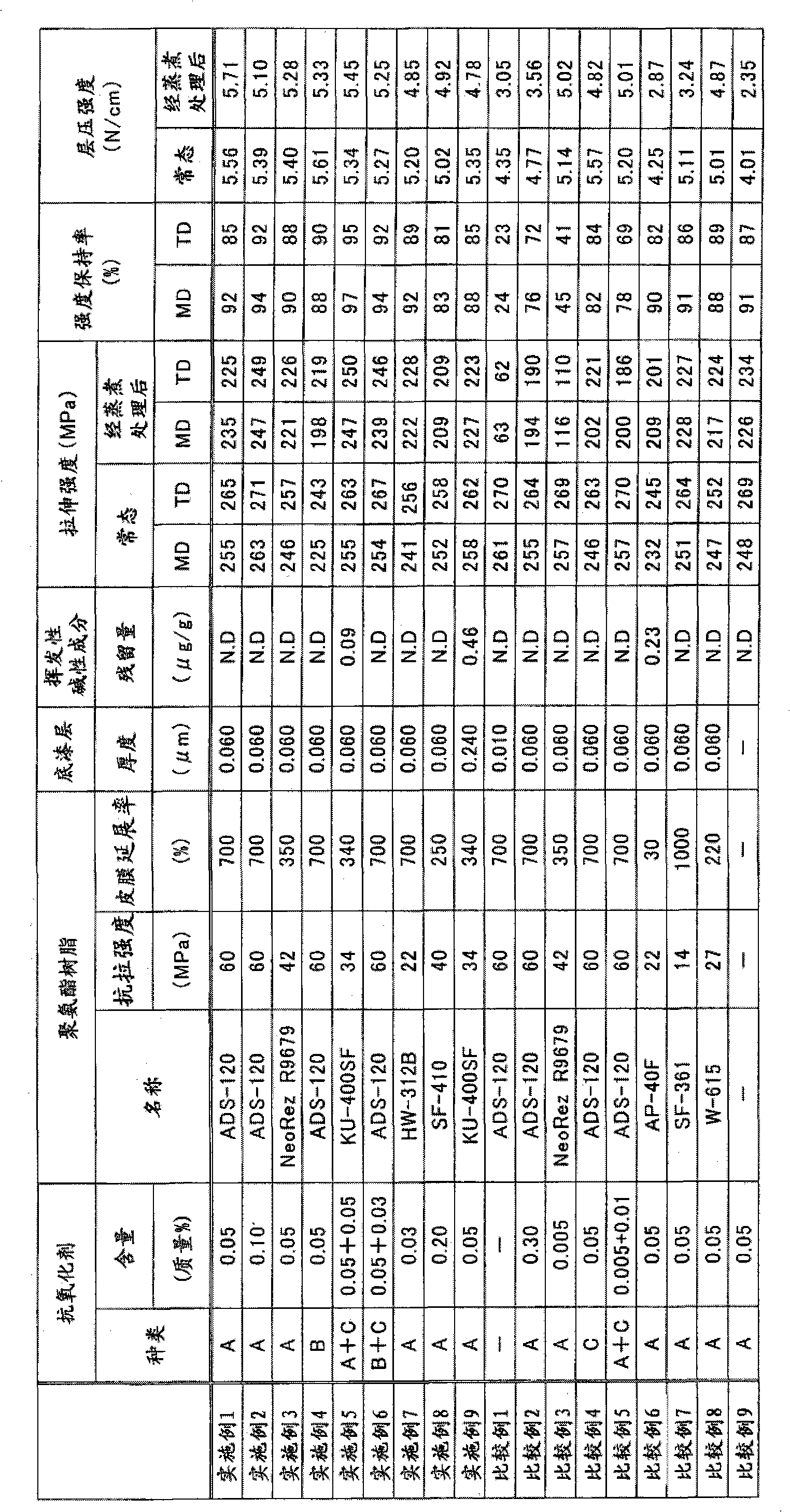

Examples

Embodiment 1

[0081] The polyurethane latex manufactured by DIC ADS-120" (solid content concentration 50% by mass) was diluted with ion-exchanged water to produce a water-based primer paint with a resin solid content of 10% by mass.

[0082] And used the following composition, that is, with respect to nylon 6 (relative viscosity 3.0 (25 ℃, 95 mass% sulfuric acid)) 99.80% by mass, as a hindered phenolic compound belonging to the antioxidant tetra[3-(3 , 5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester (hereinafter referred to as "antioxidant A") is 0.05% by mass, and ethylene bisstearic acid amide as an organic lubricant is 0.15 The composition obtained by blending in mass %. The composition was mixed and melted at 240°C, and then extruded into a sheet with a T die, then it was adhered to a rotating drum at 25°C and quenched to obtain an unstretched substrate with a thickness of 150μm. film.

[0083] Next, the above-mentioned water-based paint was applied on the unstretch...

Embodiment 2

[0086] Compared with Example 1, the content of antioxidant A was changed to 0.10% by mass. Otherwise, the same operation as in Example 1 was performed to obtain a biaxially oriented polyamide film. The evaluation results of the obtained polyamide film are shown in Table 1.

Embodiment 3

[0088] Compared with Example 1, the polyurethane resin used was changed to "NeoRez R9679" (solid content concentration 37% by mass) manufactured by DSM Corporation, and it was diluted with ion exchange water to a solid content concentration of 10% by mass, and used as an aqueous paint. Otherwise, the same operations as in Example 1 were carried out to obtain a biaxially stretched polyamide film. The evaluation results of the obtained polyamide film are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com