Preparation method of fluorine-containing soap-free emulsion repellent

A soap-free emulsion and protective agent technology, which is applied in the production of coatings and bulk chemicals, can solve the problems of high energy consumption, prone to violent polymerization, and non-flammability, so as to improve the yield and purity and avoid the phenomenon of violent polymerization , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

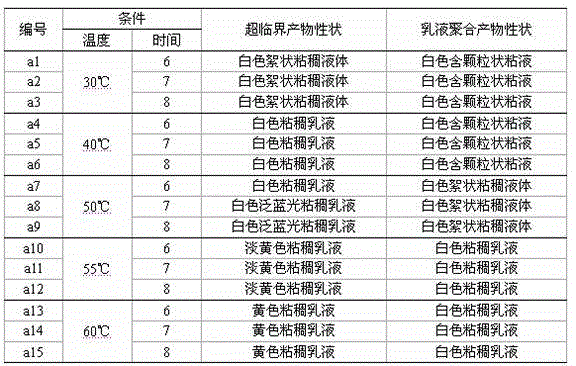

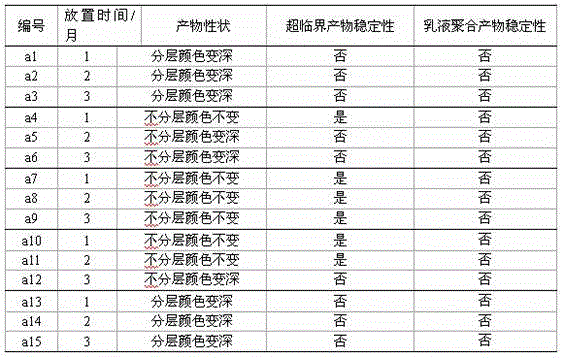

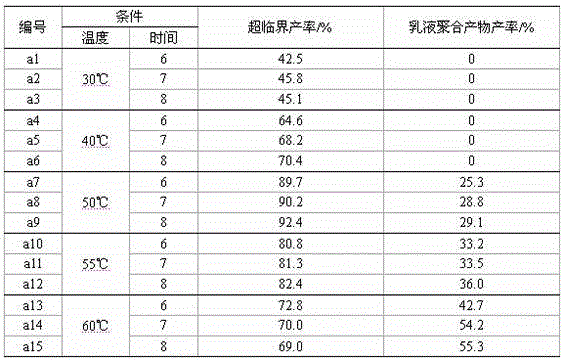

Image

Examples

Embodiment 1

[0021] (1) Mix the composite initiation system composed of polytetrafluoroethylene, azobisisobutyronitrile and azobisisoheptanonitrile at a mass ratio of 1:0.05, wherein the composite initiation system includes azobisisobutyronitrile, azo The mass ratio of diisoheptanonitrile is 1:0.5, then add water, then add 2-methyl methacrylate, the ratio of the added quality to polytetrafluoroethylene is 1:10, add 2-methyl methacrylate The speed is one drop per second, and finally adjust the pH of the mixed solution to 3, control the temperature to 80°C, and stir for 1 hour to obtain the mixed solution A, wherein the water added is 10% of the solution mass before adjusting the pH;

[0022] (2) Under the protection of nitrogen atmosphere, the redox system composed of mixed liquid A, styrene, dihydrocarbon peroxide and tertiary amine fatty acid ferrous salt, and hydroquinone are mixed and then added to the reaction in the presence of supercritical carbon dioxide medium Polymerization is car...

Embodiment 2

[0024] (1) Mix the composite initiation system composed of polyhexafluoroethylene, dimethyl azobisisobutyrate and azobisisobutyronitrile at a mass ratio of 1:0.05, wherein the composite initiation system contains azobisisobutyronitrile The mass ratio of dimethyl methacrylate and azobisisobutyronitrile is 1: 2, then add water, then add 2-ethyl methacrylate, the ratio of the added quality to polyhexafluoroethylene is 1: 10, add 2 - The speed of ethyl methacrylate is one drop per second, and finally adjust the pH of the mixed solution to 7, and control the temperature to 80°C, stir and react for 1 hour to obtain mixed solution A, wherein the water added is 10% of the solution quality before pH adjustment %;

[0025] (2) Under the protection of a nitrogen atmosphere, mix the mixed solution A, n-butyl acrylate, the oil-soluble initiator as a redox system composed of dihydrocarbon peroxide and cuprous naphthenate, and mix tert-butyl quinone and add organic Carry out polyreaction in...

Embodiment 3

[0027] (1) Mix polyhexafluoropropylene oxide and water-soluble initiators such as azobisisobutyronitrile and azobisisoheptanonitrile in a mass ratio of 1:0.05, and the two substances in the composite initiation system The mass ratio is 1:1.5, then add water, then add 4-methylstyrene, the ratio of the added quality to polyhexafluoropropylene oxide is 1:10, and the speed of adding 4-methylstyrene is per second One drop, finally adjust the pH of the mixed solution to 6, control the temperature to 80°C, stir and react for 1 hour to obtain the mixed solution A, wherein the water added is 10% of the mass of the solution before adjusting the pH;

[0028] (2) Under the protection of a nitrogen atmosphere, mix the mixed solution A, isooctyl acrylate, the oil-soluble initiator is a redox system composed of dihydrocarbon peroxide and tertiary amine fatty acid ferrous salt, and add copper naphthenate. Carry out polymerization reaction in the reactor that supercritical carbon dioxide mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com