Montmorillonite-modified organic silicon graft polyester type polyurethane elastomer, and preparation method and application thereof

A technology of polyurethane elastomer and grafted polyester is applied in the field of montmorillonite modified organosilicon grafted polyester polyurethane elastomer and its preparation, which can solve the problems of reducing the mechanical properties of materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

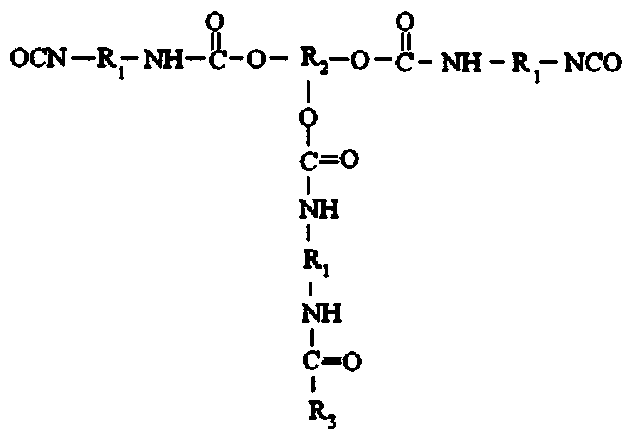

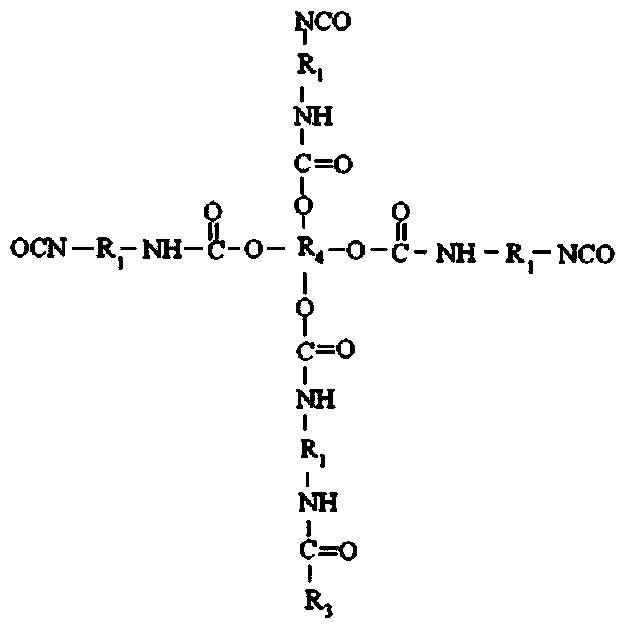

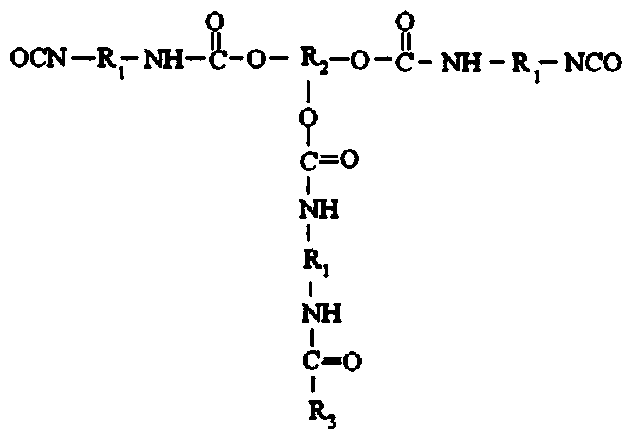

Method used

Image

Examples

Embodiment 1

[0093] (1) Preparation of polyester polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 17.4g of toluene diisocyanate (TDI) and 100g of toluene diisocyanate (TDI) with an average molecular weight of 2000 and a hydroxyl value of 54-58 polyethylene adipate diol, stirred and reacted at 75°C for 5 hours to obtain a polyester polyurethane prepolymer;

[0094](2) Preparation of silicone-grafted polyester polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 100g of polystyrene with an average molecular weight of 3000 and a hydroxyl value of 56-60. Ethylene glycol trimethylolpropane adipate polyol and 18g toluene diisocyanate (TDI) were stirred and reacted at 80°C for 4h, and then 6g of single-terminal hydroxyl polydimethylsiloxane (silanol-terminated, average The molecular weight is 15000), 0.1g organome...

Embodiment 2

[0098] (1) Preparation of polyester polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 17g of hexamethylene diisocyanate (HDI) and 100g of hexamethylene diisocyanate (HDI) with an average molecular weight of 2000, hydroxyl Polycaprolactone diol with a value of 55-58 was stirred and reacted at 85°C for 6 hours to obtain a polyester polyurethane prepolymer;

[0099] (2) Preparation of silicone-grafted polyester polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 100g of polystyrene with an average molecular weight of 1500 and a hydroxyl value of 110-116. Caprolactone trihydric alcohol and 34g hexamethylene diisocyanate (HDI), after stirring and reacting at 85°C for 4h, add 30g single-end hydroxyl polydimethylsiloxane (silanol-terminated, average molecular weight is 50000), 0.1g of dibutyltin dilau...

Embodiment 3

[0103] (1) Preparation of polyester polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 67g of isophorone diisocyanate (IPDI) and 100g of an average molecular weight of 500, hydroxyl The polycarbonate diol with a value of 220-230 was stirred and reacted at 75°C for 10 hours to obtain a polyester polyurethane prepolymer;

[0104] (2) Preparation of silicone-grafted polyester polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 100g of polystyrene with an average molecular weight of 2000 and a hydroxyl value of 110-114. Carbonate polyol, 45g of isophorone diisocyanate (IPDI), after stirring and reacting at 75°C for 7h, add 15g of single-end hydroxyl polydimethylsiloxane (silanol-terminated, average molecular weight is 30000), 0.4 g dibutyltin dilaurate, heat up to 95°C, carry out graft modification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com