An Electrolyte Resistant Pigment Printing Thickener

An electrolyte-resistant and paint-printing technology, applied in the field of paint-printing thickeners, can solve problems such as poor coordination between electrolyte-resistant ability and thickening effect, and achieve the effects of improving product storage stability, stable and gentle reaction, and reducing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

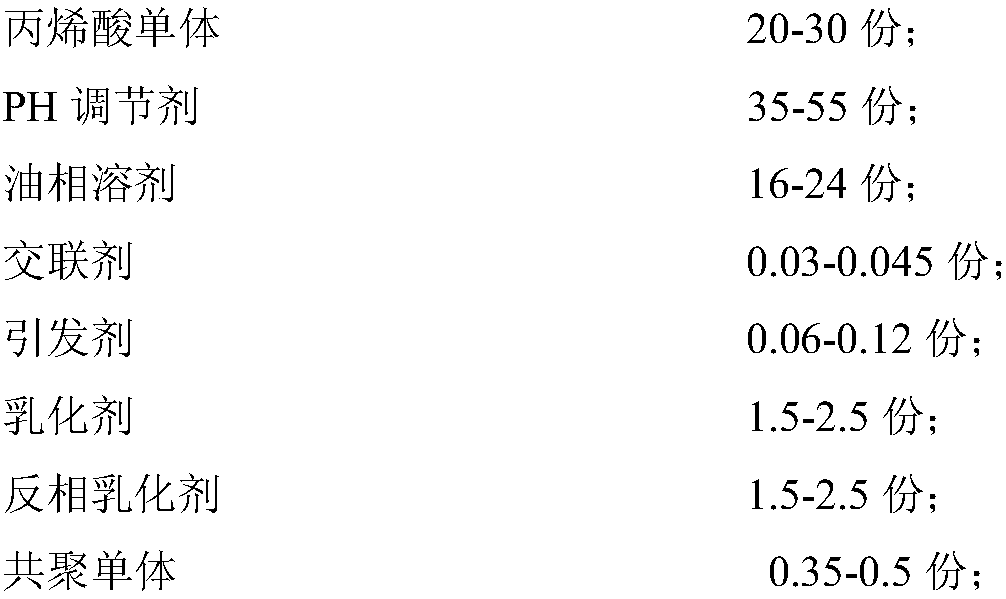

[0033] An electrolyte-resistant pigment printing thickener, by weight, comprising the following components:

[0034] Acrylic acid monomer 20 parts;

[0035] 35.5 parts of pH regulator;

[0036] 16 parts of oil phase solvent;

[0037] 0.03 parts of crosslinking agent;

[0038] 0.08 parts of initiator;

[0039] 1.6 parts of emulsifier;

[0040] 1.6 parts of inverse emulsifier;

[0041] 0.42 parts of comonomer;

[0042] Its preparation method comprises the following steps:

[0043] (1) Under the condition of stirring, slowly add the pH regulator dropwise to neutralize the acrylic acid monomer, and keep stirring so that the neutralization temperature does not exceed 40°C.

[0044] (2) Add initiator ammonium persulfate and a crosslinking agent to the neutralized solution in step (1) to obtain an aqueous phase.

[0045] (3) Mix the oil phase solvent, emulsifier and comonomer, and stir at high speed to obtain the oil phase.

[0046] (4) Mix the water phase obtained in step (...

Embodiment 2

[0049] An electrolyte-resistant pigment printing thickener, by weight, comprising the following components:

[0050] Acrylic acid monomer 25 parts;

[0051] 44.3 parts of pH regulator;

[0052] 20 parts of oil phase solvent;

[0053] 0.038 parts of crosslinking agent;

[0054] Initiator 0.01 part;

[0055] 2.0 parts of emulsifier;

[0056] 2.0 parts of inverse emulsifier;

[0057] 0.42 parts of comonomer;

[0058] Its preparation method comprises the following steps:

[0059] (1) Under the condition of stirring, slowly add the pH regulator dropwise to neutralize the acrylic acid monomer, and keep stirring so that the neutralization temperature does not exceed 40°C.

[0060] (2) Add initiator ammonium persulfate and a crosslinking agent to the neutralized solution in step (1) to obtain an aqueous phase.

[0061] (3) Mix the oil phase solvent, emulsifier and comonomer, and stir at high speed to obtain the oil phase.

[0062] (4) Mix the water phase obtained in step (2) ...

Embodiment 3

[0065] An electrolyte-resistant pigment printing thickener, by weight, comprising the following components:

[0066] Acrylic acid monomer 30 parts;

[0067] 53.3 parts of pH regulator;

[0068] 24 parts of oil phase solvent;

[0069] 0.045 parts of crosslinking agent;

[0070] 0.12 parts of initiator;

[0071] 2.4 parts of emulsifier;

[0072] 2.4 parts of inverse emulsifier;

[0073] 0.48 parts of comonomer;

[0074] Its preparation method comprises the following steps:

[0075] (1) Under the condition of stirring, slowly add the pH regulator dropwise to neutralize the acrylic acid monomer, and keep stirring so that the neutralization temperature does not exceed 40°C.

[0076] (2) Add initiator ammonium persulfate and a crosslinking agent to the neutralized solution in step (1) to obtain an aqueous phase.

[0077] (3) Mix the oil phase solvent, emulsifier and comonomer, and stir at high speed to obtain the oil phase.

[0078] (4) Mix the water phase obtained in step (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com