Organic silicon/montmorillonite composite modified polyester-type polyurethane elastomer as well as preparation method and application thereof

A polyester polyurethane, compound modification technology, applied in the direction of silicon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of reducing the mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

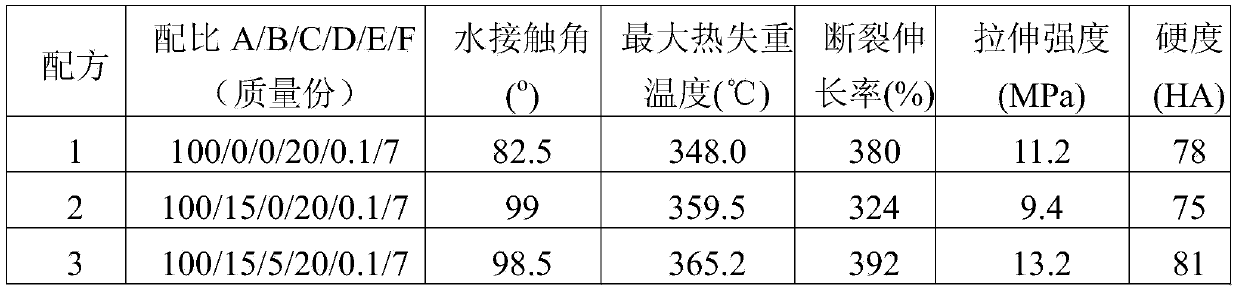

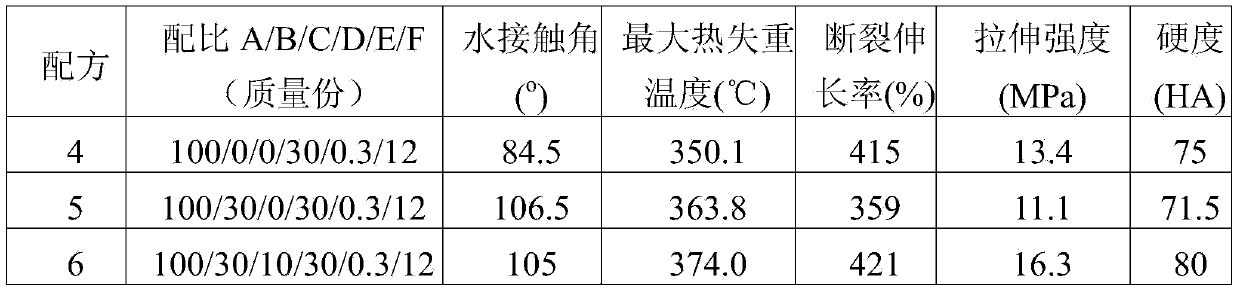

Examples

Embodiment 1

[0074] (1) Preparation of polyester polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 17.4g of toluene diisocyanate (TDI) and 100g of toluene diisocyanate (TDI) with an average molecular weight of 2000 and a hydroxyl value of 54-58 polyethylene adipate diol, stirred and reacted at 75°C for 5 hours to obtain a polyester polyurethane prepolymer;

[0075] (2) Preparation of isocyanate-terminated polydimethylsiloxane: In a 1000mL three-neck flask equipped with a mechanical electric stirrer, a thermometer, and a nitrogen gas conduit, add 12g of toluene diisocyanate (TDI), 500g of double-terminated hydroxyl poly(dimethicone) Methylsiloxane (silanol-terminated, average molecular weight 15,000) and 0.5 g of dibutyltin dilaurate were stirred and reacted for 6 hours at 90°C under the protection of nitrogen to prepare isocyanate-terminated polydimethylsiloxane ;

[0076] (3) Preparation of orga...

Embodiment 2

[0079] (1) Preparation of polyester polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 17g of hexamethylene diisocyanate (HDI) and 100g of hexamethylene diisocyanate (HDI) with an average molecular weight of 2000, hydroxyl Polycaprolactone diol with a value of 55-58 was stirred and reacted at 85°C for 6 hours to obtain a polyester polyurethane prepolymer;

[0080] (2) Preparation of isocyanate-terminated polydimethylsiloxane: In a 1000mL three-neck flask equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 5g of hexamethylene diisocyanate (HDI), 750g of double-ended Hydroxypolydimethylsiloxane (silanol-terminated, average molecular weight 50,000) and 0.7g dibutyltin dilaurate were stirred and reacted for 5 hours at 95°C under nitrogen protection to prepare isocyanate-terminated polydimethylsiloxane Silicone;

[0081] (3) Preparation of organic montmo...

Embodiment 3

[0084] (1) Preparation of polyester polyurethane prepolymer: In a 500mL three-necked bottle equipped with a mechanical electric stirrer, a thermometer, and a nitrogen conduit, add 67g of isophorone diisocyanate (IPDI) and 100g of an average molecular weight of 500, hydroxyl The polycarbonate diol with a value of 220-230 was stirred and reacted at 75°C for 10 hours to obtain a polyester polyurethane prepolymer;

[0085] (2) Preparation of isocyanate-terminated polydimethylsiloxane: In a 500-mL three-neck flask equipped with a mechanical electric stirrer, a thermometer, and a nitrogen gas conduit, add 9 g of isophorone diisocyanate (IPDI), 200 g of double-ended Hydroxypolydimethylsiloxane (silanol-terminated, average molecular weight 10,000) and 0.8 g of dibutyltin dilaurate were stirred and reacted for 7 hours at 85°C under nitrogen protection to prepare isocyanate-terminated polydimethylsiloxane Silicone;

[0086] (3) Preparation of organic montmorillonite: In a 500mL three-n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Antenna | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com