Solvent-free method for preparing tackified p-tert-butyl phenolic resin

A technology of p-tert-butylphenol and p-tert-butyl, which is applied in the field of solvent-free preparation of tackified p-tert-butylphenol-formaldehyde resin, can solve the inevitable solvent volatilization damage, environmental pollution and other problems, so as to reduce production costs and avoid exposure The effect of poly, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

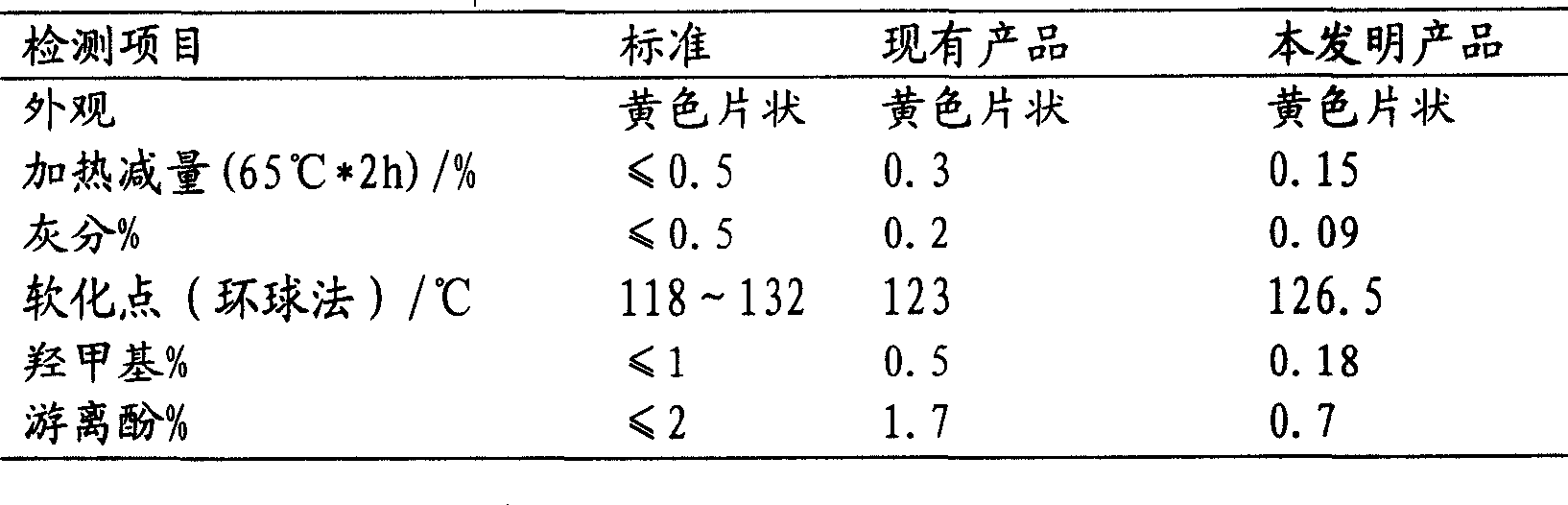

Embodiment 1

[0041] Add 150g of p-tert-butylphenol and 25g of formaldehyde into a 500mL three-necked flask, slowly heat up and melt, and stop the temperature rise when it reaches 90-95°C. Stir for 15 to 30 minutes, add 8.45 g of catalyst (hydrochloric acid) dropwise under reflux, finish adding in about 1.5 hours, and reflux at 101°C for 3 hours. After completion of the reaction, 0.55 g of sodium dodecylbenzenesulfonate was added and stirred for 10 to 20 minutes. Heating and dehydration, the system becomes transparent at 110°C, continue to heat up to 170-180°C, add 1.2g oxalic acid, stir for 10-20 minutes, vacuum dehydration for 20 minutes (vacuum degree>0.085MPa); stop the reaction, pour out the material, After cooling, a light yellow transparent flaky solid was obtained.

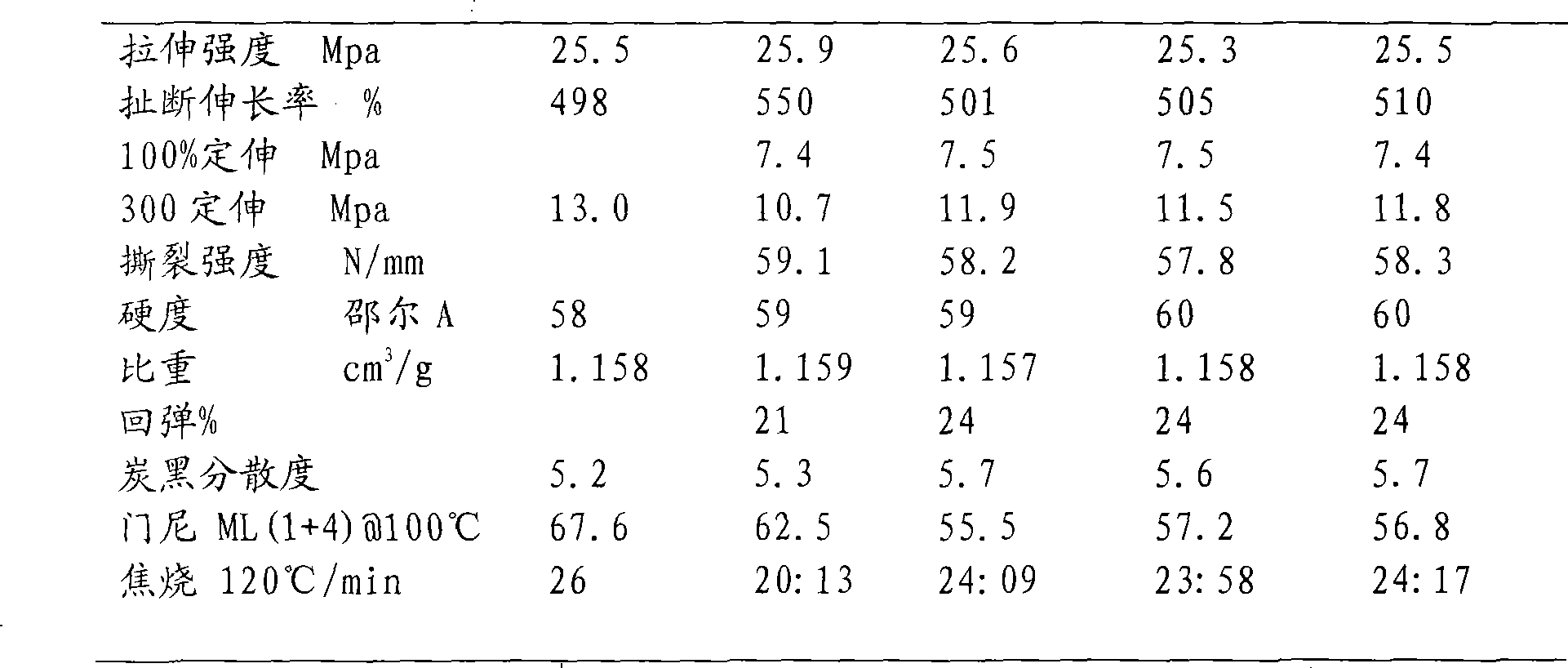

Embodiment 2

[0043] Add 400g of p-tert-butylphenol and 41.6g of formaldehyde into a 1L three-neck flask, slowly heat up and melt, and stop the temperature rise when it reaches 90-95°C. After stirring for 20 minutes, 22.5 g of catalyst (hydrochloric acid) was added dropwise under reflux, and the addition was completed in about 1.5 hours, followed by reflux at 101° C. for 3 hours. After completion of the reaction, 0.92 g of sodium dodecylbenzenesulfonate was added and stirred for 10 to 20 minutes. Heating and dehydration, the system becomes transparent at 110°C, continue to heat up to 170-180°C, add 2g of oxalic acid, stir for 10-20 minutes, vacuum dehydration for 20 minutes (vacuum degree>0.085MPa); stop the reaction, pour out the material, cool A light yellow transparent flaky solid was obtained.

Embodiment 3

[0045] Add 55kg of p-tert-butylphenol and 19kg of formaldehyde into a 200L reactor, slowly heat up and melt until it reaches 90-95°C, then stop the temperature rise. Stir for 15 to 30 minutes, add 6.5 kg of catalyst (hydrochloric acid) dropwise under reflux, finish adding in about 1.5 hours, and reflux at 101°C for 3 hours. After the reaction was completed, 0.4 kg of sodium dodecylbenzenesulfonate was added and stirred for 10 to 20 minutes. Heating and dehydration, when the system is 110°C, it becomes transparent, continue to heat up to 170-180°C, add 0.9kg oxalic acid, stir for 10-20 minutes, vacuum dehydration for 25 minutes (vacuum degree>0.085MPa); stop the reaction, pour out the material, After cooling, a light yellow transparent flaky solid was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com