Method for preparing super absorbent resin by inverse suspension polymerization

A technology of superabsorbent resin and reversed phase suspension, which is applied in the field of reversed phase suspension polymerization to prepare superabsorbent resin, which can solve problems such as instability of the reversed phase suspension polymerization system, implosion and agglomeration, difficult superabsorbent resin products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: 342.5 g of n-heptane was added to a 1 L five-necked round bottom flask equipped with a stirrer, a reflux condenser, a dropping funnel, a thermometer and a nitrogen inlet pipe. 0.75 g of triglycerol monostearate and 0.85 g of sorbitan stearate were added thereto, the temperature was raised to 50° C., and the mixture was uniformly dispersed at a stirring speed of 350 rpm.

[0049] Add 130 g of acrylic acid aqueous solution with a mass concentration of 75% (wt%) into a 500 ml Erlenmeyer flask. 130.2 g of a 32 wt% sodium hydroxide aqueous solution was added dropwise to the Erlenmeyer flask. Then, 0.5 g of potassium persulfate, 0.2 g of propylene glycol diglycidyl ether, and 0.12 g of hydroxyethyl cellulose were added thereto to obtain an aqueous solution of acrylic acid monomer.

[0050] The aqueous solution of acrylic acid monomer was added into the above-mentioned five-neck round bottom flask, and nitrogen gas was passed in for 30-60 minutes while stirring. ...

Embodiment 2

[0052] Embodiment 2: except that the consumption of tripolyglycerol monostearate and sorbitan stearate is changed into 0.9g and 0.7g, and the stirring speed is adjusted to 380rpm, other operations are the same as embodiment 1.

Embodiment 3

[0053] Example 3: 380 g of cyclohexane was added to a 1 L five-neck round bottom flask equipped with a stirrer, a reflux condenser, a dropping funnel, a thermometer and a nitrogen inlet tube. 0.7 g of triglycerol monostearate and 0.7 g of sorbitan stearate were added thereto, the temperature was raised to 50° C., and the mixture was uniformly dispersed at a stirring speed of 320 rpm.

[0054] 130 g of 75 wt% aqueous acrylic acid was added to a 500 ml Erlenmeyer flask. 130.2 g of a 32 wt% sodium hydroxide aqueous solution was added dropwise to the Erlenmeyer flask. Then, 0.45 g of potassium persulfate, 0.015 g of propylene glycol diglycidyl ether, and 0.1 g of hydroxyethyl cellulose were added thereto to obtain an aqueous solution of acrylic acid monomer.

[0055] The aqueous solution of acrylic acid monomer was added into the above-mentioned five-neck round bottom flask, and nitrogen gas was passed in for 30-60 minutes while stirring. Then the temperature of the water bath ...

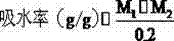

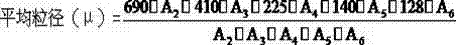

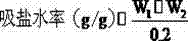

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com