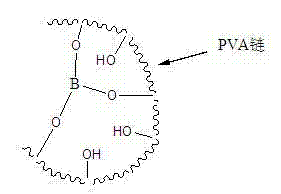

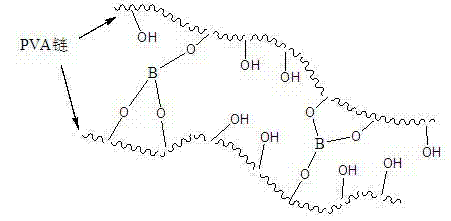

Polyvinyl alcohol-borax microsphere and preparation method thereof

A technology of polyvinyl alcohol and borax, which is applied in the field of polyvinyl alcohol-borax microspheres and their preparation, can solve problems such as irritation and achieve the effects of good thermal stability, high utilization rate of crosslinking agent and simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The reagents used in the present invention are all medical grade or pharmaceutical grade.

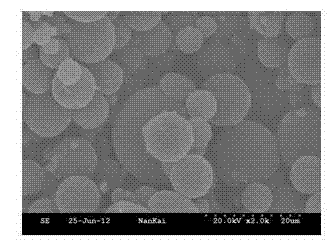

[0026] Dissolve 5g of polyvinyl alcohol (PVA) in boiling water to prepare 100ml of PVA aqueous solution with a mass fraction of 5%, adjust the pH value to 1 with 2mol / L hydrochloric acid, and use this solution as the water phase. Dissolve 2g of sorbitan oleate (Span-80) in 200ml of liquid paraffin, and use this solution as the oil phase. Add the above two solutions into a 500ml three-necked bottle, and adjust the rotation speed to 600 rpm to make the water phase liquid beads reach a suitable particle size. Dissolve 1.0 g of sodium tetraborate decahydrate (borax) in 10 ml of hydrochloric acid with a concentration of 1 mol / L and add it dropwise to the reaction system. Raise the temperature to 60°C for 4 hours, observe the particle size of the PVA spherical gel particles in the system at this time with a microscope, then add 10ml of medicinal sodium phosphate solution with a mass f...

Embodiment 2

[0028] Dissolve 10g of polyvinyl alcohol (PVA) in boiling water to obtain 100ml of PVA aqueous solution with a mass fraction of 10%, adjust the pH value to 1 with 2mol / L hydrochloric acid, and use this solution as the water phase. Dissolve 8 g of sorbitan oleate (Span-80) in 200 ml of liquid paraffin, and use this solution as the oil phase. Add the above two solutions into a 500ml three-necked bottle, and adjust the rotation speed to 700 rpm to make the water phase liquid beads reach a suitable particle size. Dissolve 4.0 g of sodium tetraborate decahydrate (borax) in 30 ml of hydrochloric acid with a concentration of 1 mol / L and add it dropwise to the reaction system. Raise the temperature to 60°C for 4 hours, observe the particle size of the PVA spherical gel particles in the system at this time with a microscope, then add 10ml of medicinal sodium phosphate solution with a mass fraction of 20%, and raise the temperature to 90°C to solidify the PVA spherical gel particles. C...

Embodiment 3

[0030] Dissolve 8g of polyvinyl alcohol (PVA) in boiling water to prepare 100ml of PVA aqueous solution with a mass fraction of 8%, adjust the pH value to 1 with 2mol / L hydrochloric acid, and use this solution as the water phase. Dissolve 5 g of sorbitan oleate (Span-80) in 200 ml of liquid paraffin, and use this solution as the oil phase. Add the above two solutions into a 500ml three-necked bottle, and adjust the rotation speed to 650 rpm to make the water phase liquid beads reach a suitable particle size. Dissolve 1.0 g of sodium tetraborate decahydrate (borax) in 10 ml of hydrochloric acid with a concentration of 1 mol / L and add it dropwise to the reaction system. Raise the temperature to 60°C for 4 hours, observe the particle size of the PVA spherical gel particles in the system at this time with a microscope, then add 10ml of medicinal sodium phosphate solution with a mass fraction of 20%, and raise the temperature to 90°C to solidify the PVA spherical gel particles. Cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com