Preparing method of gel microsphere material absorbing molybdate

A gel microsphere, molybdate technology, applied in chemical instruments and methods, anion exchange, ion exchange, etc., to achieve the effects of convenient operation, mild and controllable reaction conditions, and good swelling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

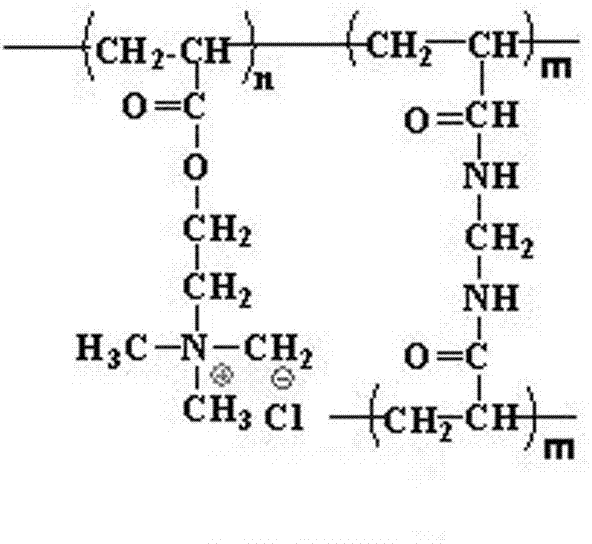

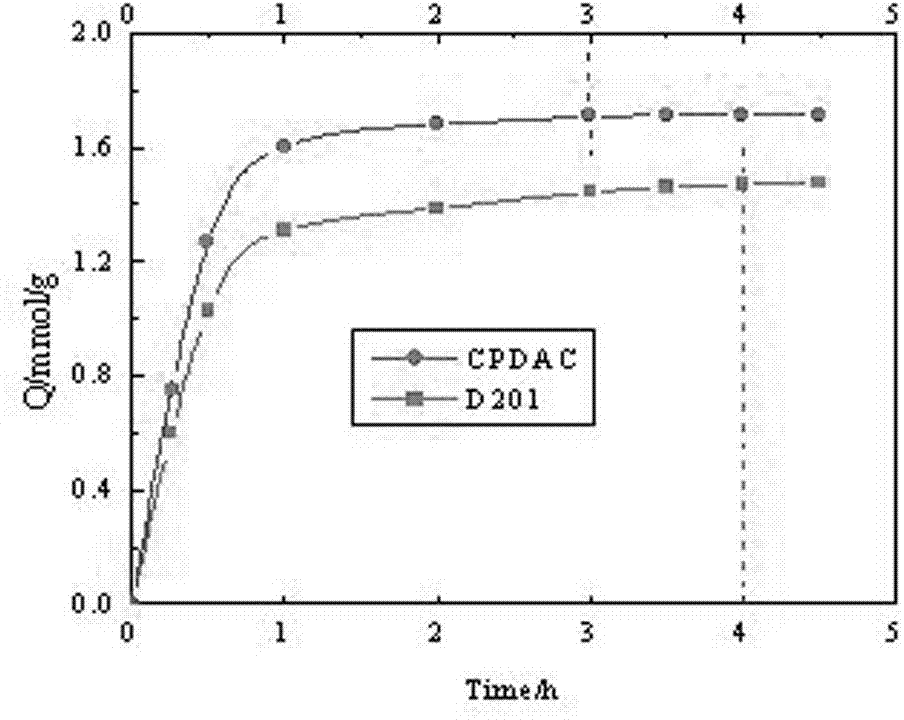

[0017] A kind of preparation method of the gel microsphere material of adsorption molybdate radical, comprises the steps:

[0018] First, prepare the oil phase and the water phase: use span60 as the dispersant and cyclohexane as the dispersion medium to form the continuous oil phase, wherein the amount of the dispersant Span-60 accounts for 3.5-4.6% of the dispersion medium cyclohexane; The aqueous solution of acryloyloxyethyltrimethylammonium chloride DAC and N,N-methylene bisacrylamide MBA is used as the water phase, wherein the concentration of acryloyloxyethyltrimethylammonium chloride DAC is 2.76mol / L, The concentration of N,N-methylenebisacrylamide MBA is 0.16mol / L;

[0019] Then, in a four-neck flask equipped with a stirrer, a condenser, and an air guide tube, add the oil phase, and pass nitrogen gas for 30 minutes to remove the air in the flask, and heat it to 55°C;

[0020] Afterwards, add the ammonium persulfate that initiator concentration is 0.16mol / L again in wat...

Embodiment 1

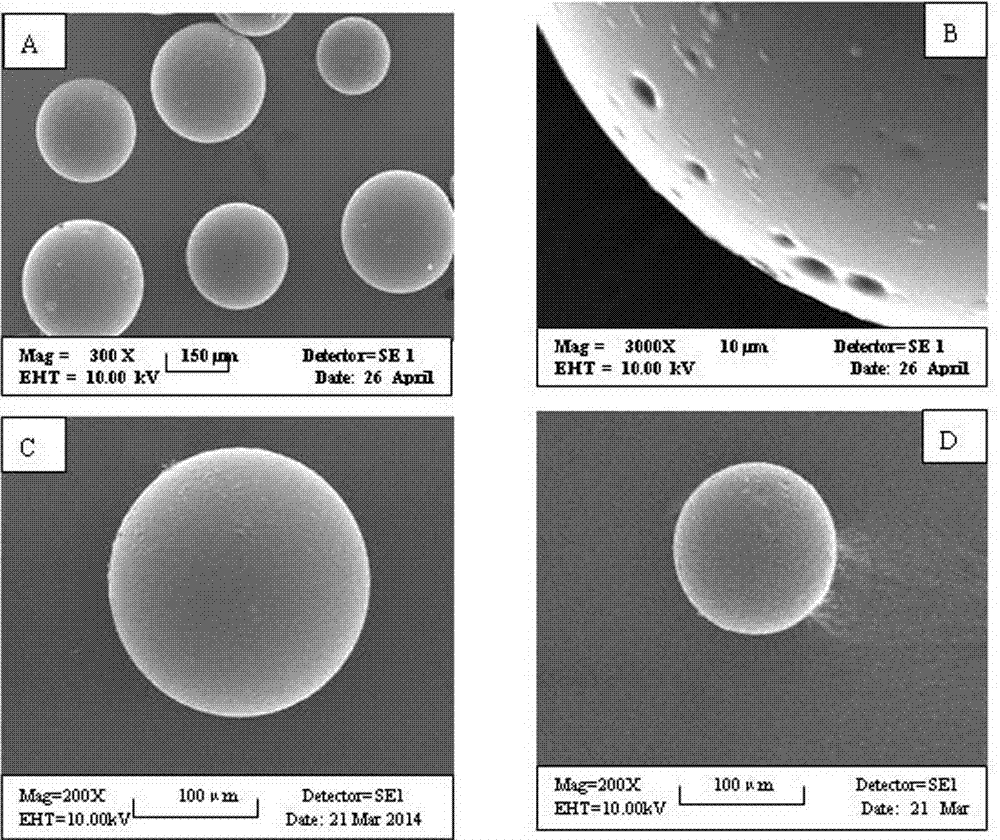

[0023] In a four-necked flask equipped with a stirrer, a condenser, and an air duct, add 27 mL of cyclohexane, and then add 0.95 g of dispersant span60 to form the continuous oil phase; add 6.3 mL of acryloyloxyethyl tris Methyl ammonium chloride (DAC), 0.34g N,N , -Methylenebisacrylamide (MBA) is miscible with 7ml of distilled water to form the aqueous phase. Nitrogen was passed through the oil phase for 30 minutes to remove the air in the system, and it was heated to 55°C; 0.032g of initiator ammonium persulfate was added to the water phase, and quickly transferred to a constant pressure dropping funnel after dissolving , slowly added dropwise to the oil phase under stirring at a certain speed, and the dropwise addition was completed within 10 minutes, then the temperature of the system was rapidly raised to 65°C, the stirring rate was controlled at 300rpmin, and the suspension polymerization reaction was carried out for 4 hours under the protection of nitrogen. The microsp...

Embodiment 2

[0025] In a four-necked flask equipped with a stirrer, a condenser, and an air duct, add 46 mL of cyclohexane, and then add 1.84 g of dispersant span60 to form the continuous oil phase; add 6.3 mL of acryloyloxyethyl tris Methyl ammonium chloride (DAC), 0.34g N,N , -Methylenebisacrylamide (MBA) is miscible with 7ml of distilled water to form the aqueous phase. Nitrogen was passed through the oil phase for 30 minutes to remove the air in the system, and it was heated to 55°C; 0.032g of initiator ammonium persulfate was added to the water phase, and quickly transferred to a constant pressure dropping funnel after dissolving , slowly added dropwise to the oil phase under stirring at a certain speed, and the dropwise addition was completed within 10 minutes, then the temperature of the system was rapidly raised to 65°C, the stirring rate was controlled at 500rpmin, and the suspension polymerization reaction was carried out for 4 hours under the protection of nitrogen. The microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com