Preparation method of super water absorbent resin

A super absorbent resin, water-soluble technology, applied in the field of polymer preparation, can solve the problems of difficult control of product particle size and particle size distribution, unstable suspension and dispersion system, sticking and agglomeration, etc. The effect of fast liquid speed and high water absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

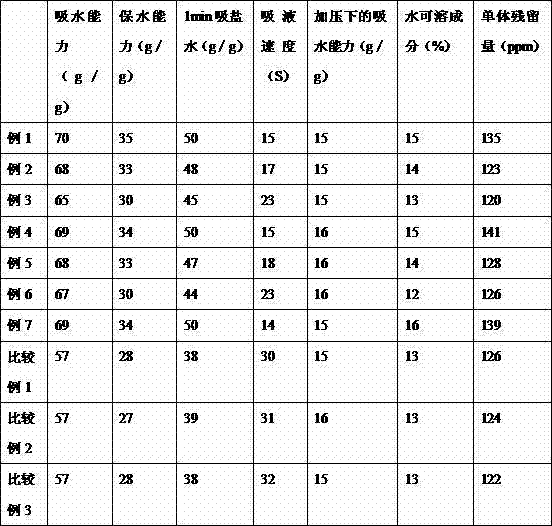

Examples

Embodiment 1

[0031] Embodiment 1: the n-heptane that takes by weighing 210g is put into the five-necked 500ml spherical flask that reflux condenser, dropping funnel, thermometer, nitrogen gas inlet tube and stirring paddle are equipped with. Add 0.2g of SPAN-20, 0.2g of SPAN-60, and 0.6g of triglycerol monostearate to the n-heptane in the flask, heat up to 70°C while stirring to dissolve the surfactant, stir at 300rpm, and cool to 50°C.

[0032] Weigh 18g of acrylic acid and 15.8g of deionized water in the Erlenmeyer flask, dropwise add 23.3g of 32% (mass percentage) sodium hydroxide aqueous solution while cooling from the outside, and after 75% (mol percentage) neutralization, add 5% ( Mass percent) potassium persulfate aqueous solution 0.54g, 2.5% (mass percent) N,N-methylenebisacrylamide aqueous solution 0.29g, add 40% (mass percent) silica sol 1.8g, stir well, and prepare the first 1-step monomer aqueous solution. Add all the monomer aqueous solution in the first step into the above-...

Embodiment 2

[0035] Example 2: Except when preparing the monomer aqueous solution in the first step in Example 1, the addition content is 40% (mass percentage) silica sol becomes 0.9g, when preparing the monomer aqueous solution in the second step, the addition content is 40% (mass percentage) silica sol becomes 1.25g, other is the same as embodiment 1.

Embodiment 3

[0036] Embodiment 3: except that when preparing the monomer aqueous solution of the 1st step in embodiment 1, do not add silica sol, when preparing the monomer aqueous solution of the 2nd step, do not add silica sol, other is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com