A Continuous Separation Process of Explosive Charge and Water Mixture

A technology for mixtures and explosives, applied in explosives processing equipment, explosives, water/sewage multi-stage treatment, etc., can solve problems such as safety accident environment, pollution, impact on environmental protection, cost safety, etc., and achieve the effect of high safety and easy collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

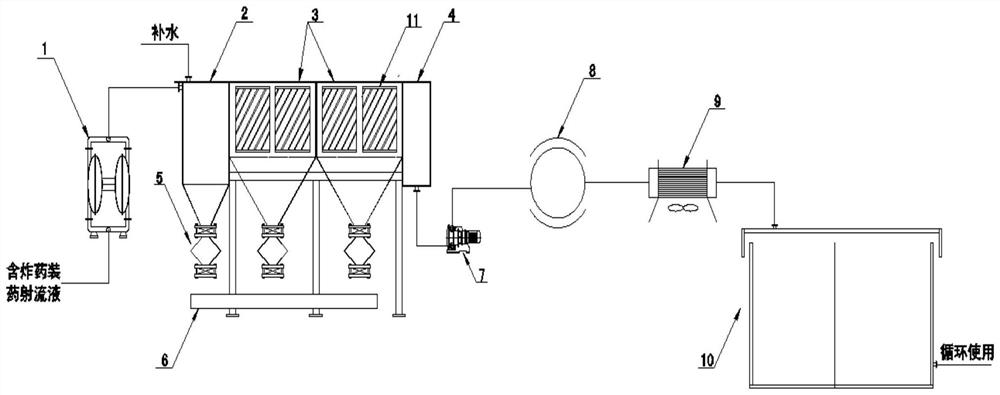

[0031] Embodiment 1: Taking the 122mm warhead filled with ladder black aluminum explosives as an example, a continuous separation process of explosive charge and water mixture is carried out according to the following steps:

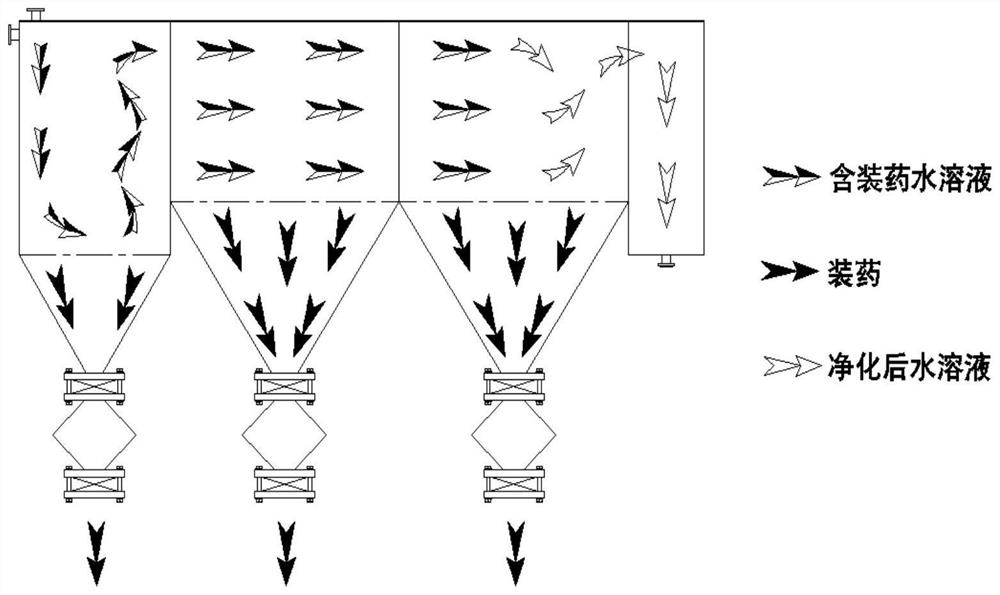

[0032] Step 1: Use the pneumatic double-diaphragm pump 1 to drive the ladder black aluminum / water solution after jetting out into the rough purification unit 2, adjust the air intake flow rate of the pneumatic double-diaphragm pump, and control the liquid output of the pneumatic double-diaphragm pump to 85L / min ;

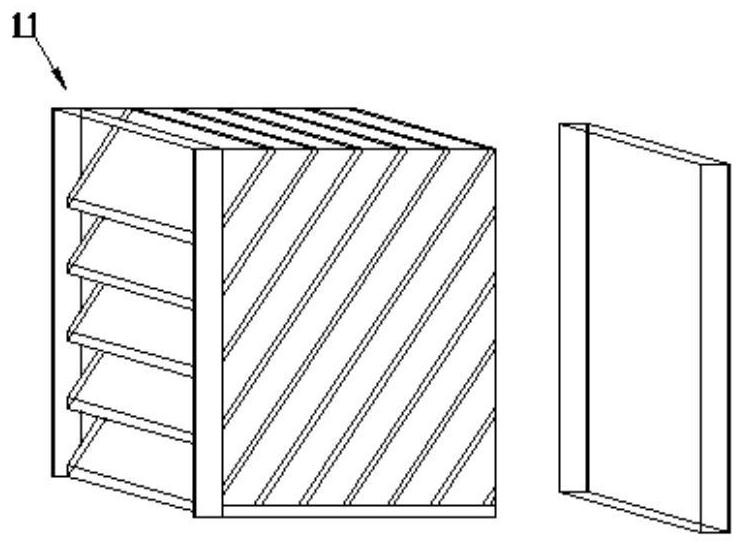

[0033] Step 2: The ladder black aluminum / water solution constantly changes the original movement direction in the internal labyrinth baffle assembly of the rough purification unit 2, and enters the solid particle collection lock chamber 5 along the surface of the rectangular cone at the bottom of the rough purification unit 2, and sets the labyrinth stop The inclination angle of the plate is 60°, the cone angle of the rectangular cone is 45°, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com