A device for recovering oil spilled from the seabed after a marine accident

A technology of accidents and shipping, applied in the direction of cleaning, separation methods, chemical instruments and methods on open water surfaces, can solve problems such as seawater oil pollution, waste of precious oil resources, and harm to the marine ecological environment, and achieve reasonable design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

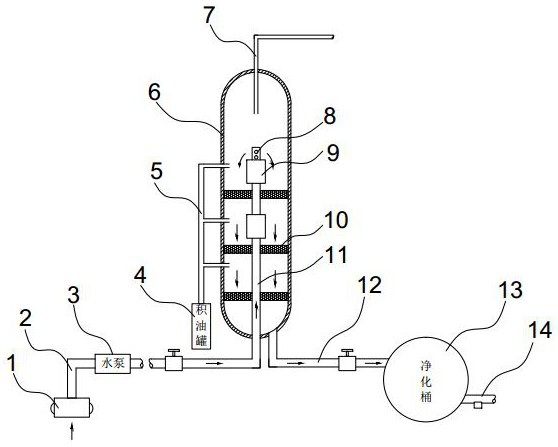

[0029] see Figure 1-4 As shown, the device used to recover oil leaked from the seabed after a marine accident has

[0030] The upper and lower sealing barrel-shaped separation tank 6, the separation tank 6 is divided into at least three chambers from top to bottom by the hydrophilic fiber block 10, the separation tank 6 is provided with a coaxial liquid inlet pipe 11, and the liquid inlet pipes in each chamber of the separation tank 6 11 is provided with a throw-out mechanism 9, and a water outlet 8 is provided at the connection with the throw-off mechanism 9, and each chamber is provided with an oil suction pipe 5, and the bottom of the separation tank 6 is connected to a water outlet pipe 12 at the bottom of the chamber;

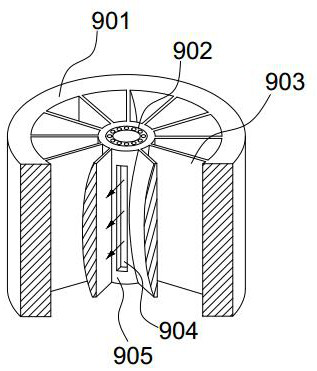

[0031] The ejection mechanism 9 includes two coaxial inner tubes 905 and outer tubes 901, and the inner and outer tubes are evenly distributed with arc-shaped rotary blades 903 in section, and the inner tube 905 between the two rotary blades 903 is provid...

Embodiment 2

[0044] This embodiment provides another kind of device technical solution for recovering seabed oil leakage after a marine accident. This technical solution further adds the following technical solution on the basis of embodiment 1: as Figure 5 As shown, a curved filter plate 10a is provided inside the hydrophilic fiber block 10 of the present invention. The cross section of the curved filter plate 10a is in a concave state, and the mesh of the curved filter plate 10a is 100-200 mesh. The present invention utilizes the arc-shaped filter plate 10a to guide the treated water flowing through the hydrophilic fiber block 10 so that it flows along the arc-shaped filter plate 10a in the hydrophilic fiber block 10 to the center of the hydrophilic fiber block 10 and flows downward. Correspondingly, increasing the central pressure of the hydrophilic fiber block 10 increases the passing rate of the water body passing through the hydrophilic fiber to reduce the clogging probability of the...

Embodiment 3

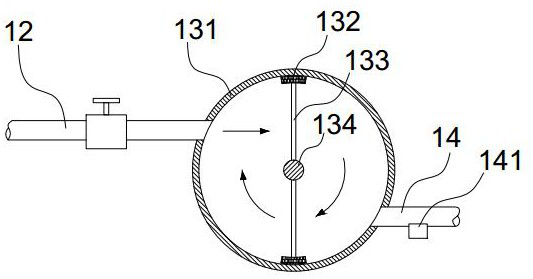

[0046] When the device of the present invention for recovering seabed oil leakage after a marine accident is actually used: when oil leakage occurs in the sea area, surround the plastic pipe around the leakage range and seal it with a clip at the joint, such as Figure 6 As shown, the water pump 3, the suction pipe 2 and the liquid inlet pipe 11 are used to send the treated water containing more leaked oil in the upper layer of the sea into the separation tank 6, and the treated water leaked from the sea surface is pumped into the top chamber of the separation tank 6 for use. It flows from top to bottom under the action of gravity, and the oil and water are separated through the hydrophilic fiber block 10. The oil suction pipe 5 absorbs and concentrates the separated oil into the oil storage tank 4 for subsequent treatment, and the treated water flows down to the separation tank under the action of gravity 6. After the water body at the bottom most has very little oil content, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com