Process and device for electrochemical treatment of industrial wastewater and drinking water

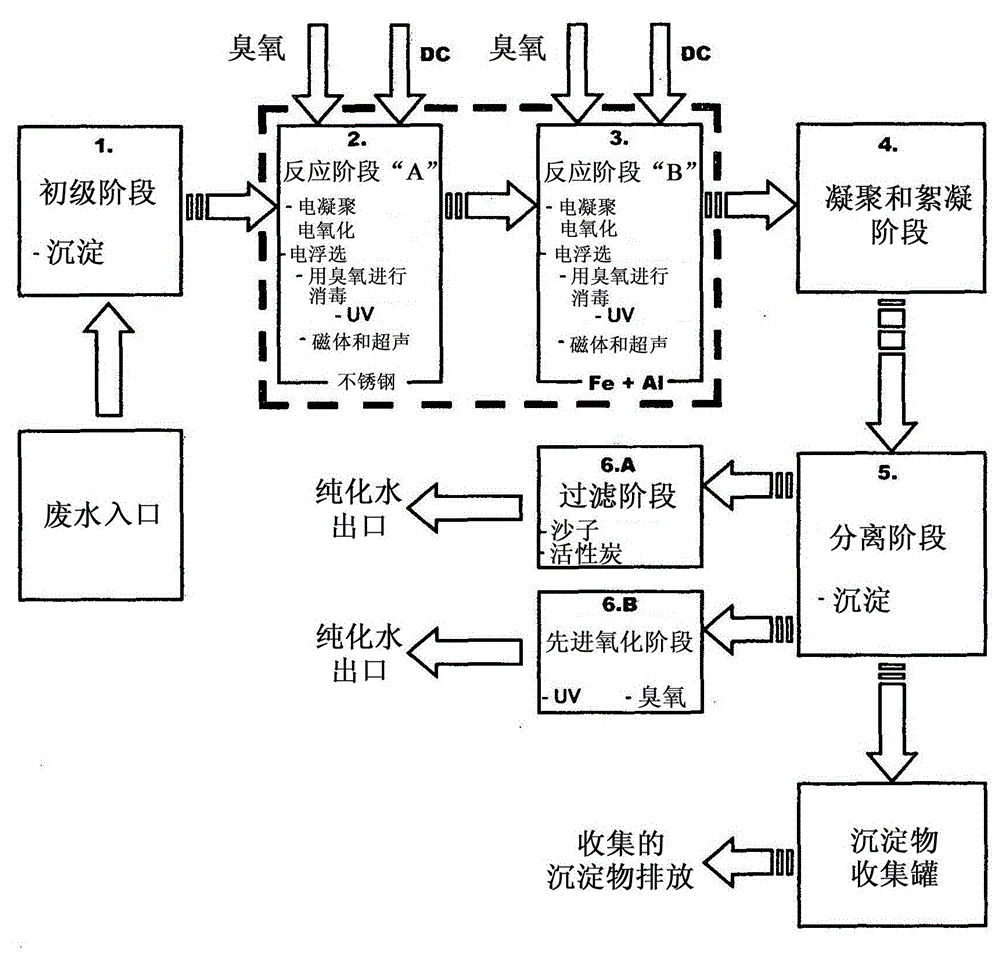

An industrial wastewater and electrochemical technology, applied in chemical instruments and methods, oxidized water/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve problems such as pH value adjustment, and achieve the effect of simplifying structure and technical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

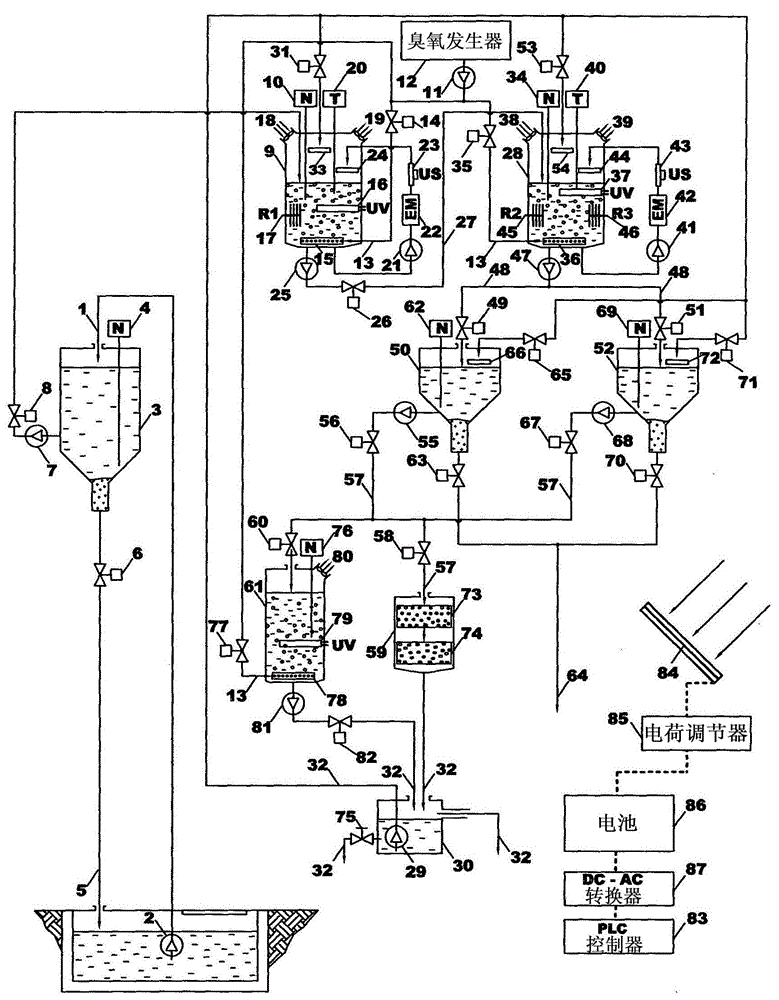

[0185] Example 1 - Treatment of Wastewater Generated After Pressure Washing of a Ship

[0186] In the treatment of waste water produced after pressure washing of ships coated with antifouling agents, devices for electrochemical treatment of industrial waste water are used. The pressure pump 2 pumps the collected waste water 1 into a water preparation tank with a total volume of 3000 L, where, during the first stage of treatment, it is kept standing still for T m = 60 min. Coarse dirt particles, sand and undissolved paint chips separate at the bottom of the water preparation tank.

[0187] After settling, the water pump 7 transfers the water from the water preparation tank 3 to the 220 l volume reactor vessel 9, where, at T 1 Ozonation and mixing of water and ozone was initiated for a duration of =30 min. Ozone 13 from the ozone generator 12 is pumped to the bottom of the reactor vessel at a flow rate of Q=5 l / min, whereby the organics are oxidized while mixing in the reacto...

Embodiment 2

[0206] Embodiment 2-for the treatment of the wastewater produced in the electroplating process

[0207] The electrochemical treatment unit for industrial wastewater is used to treat the wastewater generated during the electroplating process.

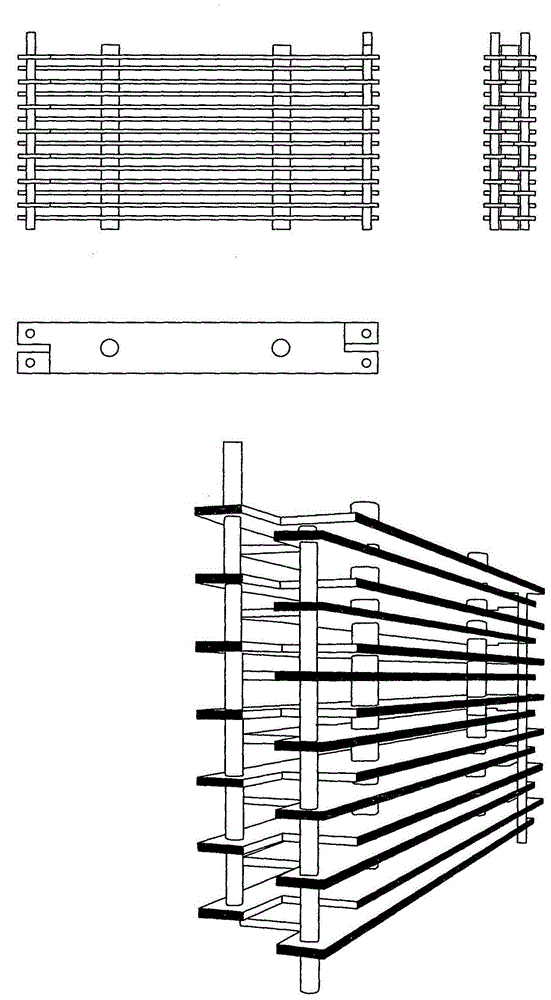

[0208] From a neutral reservoir, waste water 1 is pumped by means of a pressure pump 2 into a reactor vessel 28 of volume 2201. The water level in the reaction vessel 28 is maintained at a set limit by means of a liquid level regulator 34, and when the water in the reactor vessel 28 reaches the design water level, the steel reactor electrode group R2 is turned on and has P 1 =0.6552m 2 total surface. The reactor electrode set R2 is at the duration T 1 = Intrinsic U within 15min 1 = 12V and I 1 Operation under =45A forms the electrochemical corrosion of the anode, in which Fe 2+ Ions are released into the water and reduce chromium(VI) to chromium(III), while Fe 2+ Oxidized to Fe 3+ . OH formed during the water reduction reaction ...

Embodiment 3

[0242] Example 3 - Preparation of drinking water

[0243] Groundwater from the borehole, loaded with heavy metals, arsenic, organics, and ammonia, is treated with an electrochemical treatment facility.

[0244] The raw water 1 from the receiving tank is pumped by means of a pressure pump 2 into a reactor vessel 28 with a volume of 220 1. The water level in the reactor vessel 28 is maintained at the design level by the liquid level regulator 34, and when the water in the reactor vessel 28 reaches the desired value, the steel reactor electrode set R2 is opened and it has a total surface P 1 =0.6552m 2 . Reactor electrode group R2 in U 1 = 12V and I 1 = Maintain operation T at 50A 1 =15min, which leads to electrochemical corrosion of the anode, while Fe 2+ Ions are released into the water, performing a reduction of chromium(VI) to chromium(III), and in parallel Fe 2+ Oxidized to Fe 3+ .

[0245] Generated Fe(OH) 3 This leads to colloidal instability, which creates condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com