Apparatus for producing nanocarbon material and method for producing nanocarbon material

A technology of nano-carbon materials and manufacturing devices, which can be used in nano-structure manufacturing, nano-carbon, nano-technology, etc., and can solve the problems of complex recycling operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, with reference to the drawings, preferred embodiments of the carbon nanomaterial manufacturing apparatus according to the present invention and the carbon nanomaterial manufacturing method using the carbon nanomaterial manufacturing apparatus will be described in detail.

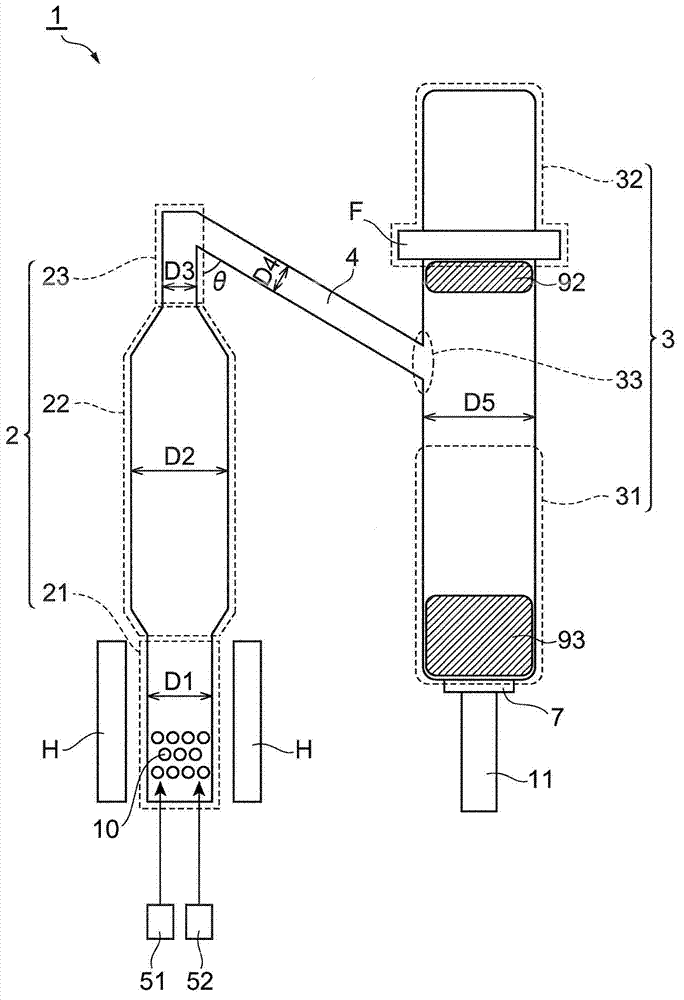

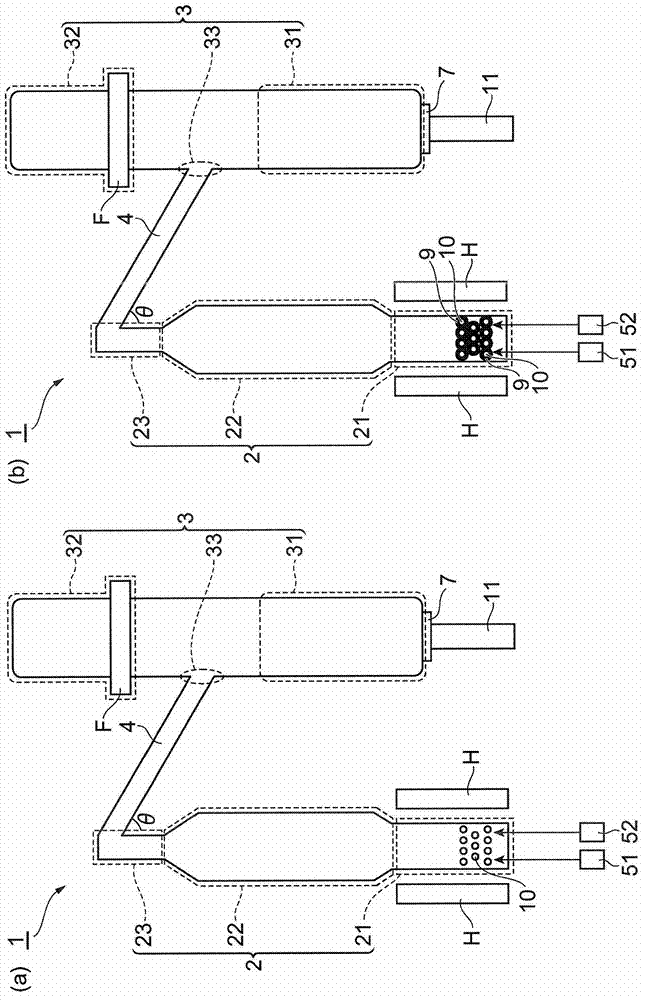

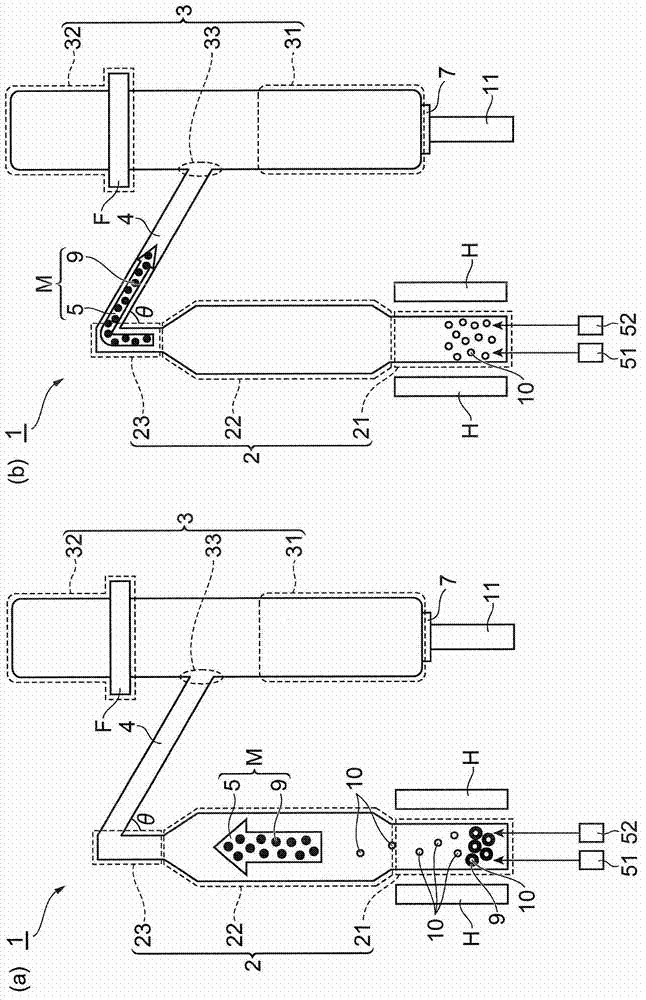

[0056] figure 1 It is a figure which shows an embodiment of the nano carbon material manufacturing apparatus concerning this invention. As shown in the figure, the carbon nanomaterial manufacturing apparatus 1 includes: a reaction tube for growing carbon nanomaterials, a recovery tube 3 for recovering the carbon nanomaterials grown in the reaction tube 2, and a connecting reaction tube 2 and a recovery tube 3 The connecting tube 4 and the heating section H that heats the reaction tube 2. Here, the nanocarbon material refers to a carbon material whose dimensions in at least one direction are in nanometer units or micrometer units, and are carbon materials having various shapes such as a fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com