Oil-water pre-separation device and treatment method based on oilfield associated gas from air flotation

An oil-water separation device and oilfield associated gas technology, which is applied in the treatment of hydrocarbon oil, mechanical dehydration/demulsification, petroleum industry, etc., can solve the problems of long separation time, low efficiency, small application range, etc., and achieve great market potential , broad application prospects, and the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

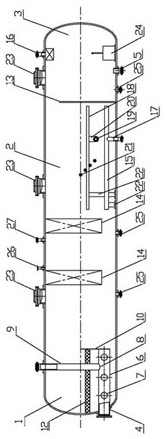

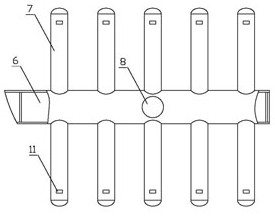

[0018] Embodiment 1: as attached figure 1 As shown, the self-air flotation oil-water pre-separation device based on oilfield associated gas includes a tank body. The inside of the tank body is divided into interconnected pretreatment chamber 1, gravity sedimentation separation chamber 2 and crude oil buffer chamber 3 from left to right. Between the treatment chamber 1 and the gravity sedimentation separation chamber 2, a baffle plate 10 is arranged to communicate with the upper and lower parts of the pretreatment chamber 1 and the gravity sedimentation separation chamber 2 respectively. The front and rear inner walls of the left part are fixedly installed together. The lower part of the pretreatment chamber 1 is fixedly equipped with a liquid distribution device. The tank body is provided with a liquid inlet pipe 9 communicating with the liquid distribution device. A liquid level stabilizing device 12 is installed in the pretreatment chamber 1 beyond the baffle plate 10, and t...

Embodiment 2

[0034] Example 2: The treatment method based on the oilfield associated gas self-air flotation oil-water pre-separation device uses the associated gas flotation in the oil well produced fluid to separate the tiny oil droplets that could not be separated by gravity settlement, and press The above method is carried out: the oilfield production fluid enters the liquid distribution main pipe 6 of the liquid distribution device from the liquid inlet pipe 9 on the top of the tank body, enters the pretreatment chamber 1 through the liquid outlet 11 on the liquid distribution branch pipe 7, and the production fluid The associated gas escapes from the liquid and carries crude oil with low density to float up to realize pre-separation. When the liquid level exceeds the baffle 10, it turns over the baffle 10 and enters the gravity sedimentation separation chamber 2, and the oil-water separation device 14 realizes the separation. For further oil-water separation, the oil layer is on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com