Gravity sedimentation separation equipment for chemical mixed liquid

A gravity sedimentation separation and liquid technology, applied in the direction of sedimentation separation, settling tank, separation method, etc., can solve the problems of incompleteness, inconvenient cleaning, and single function, and achieve the effect of preventing residue, reducing contact area, and improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

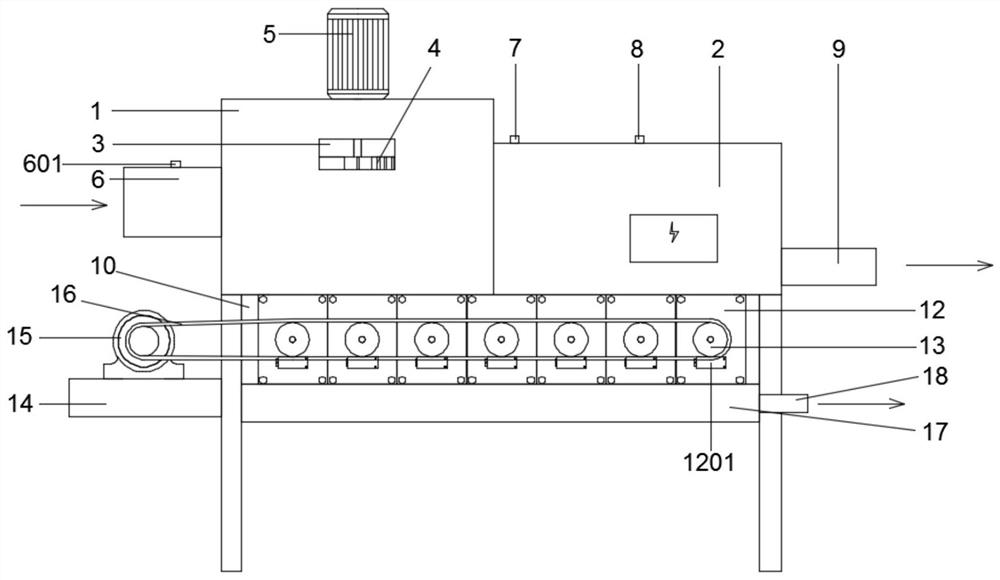

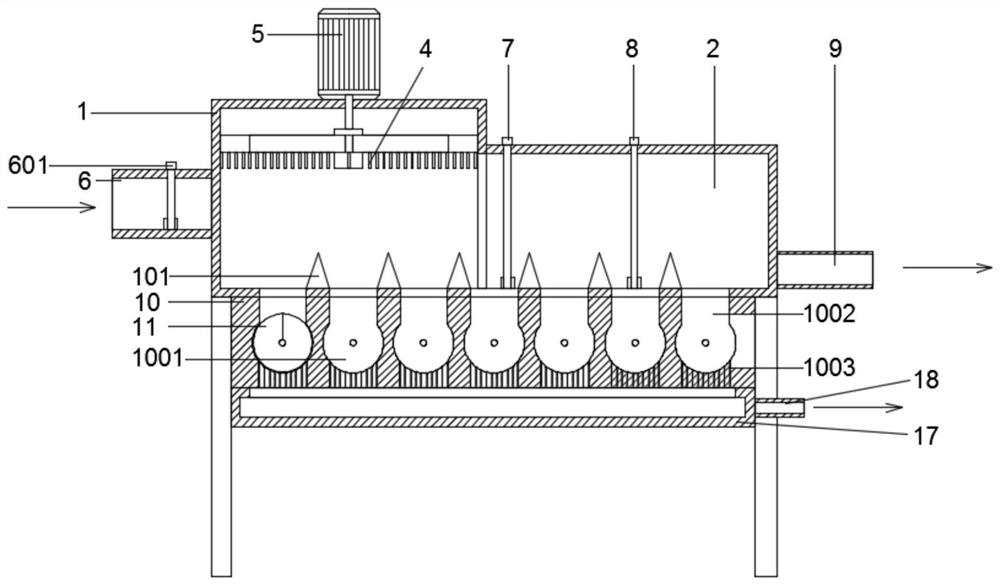

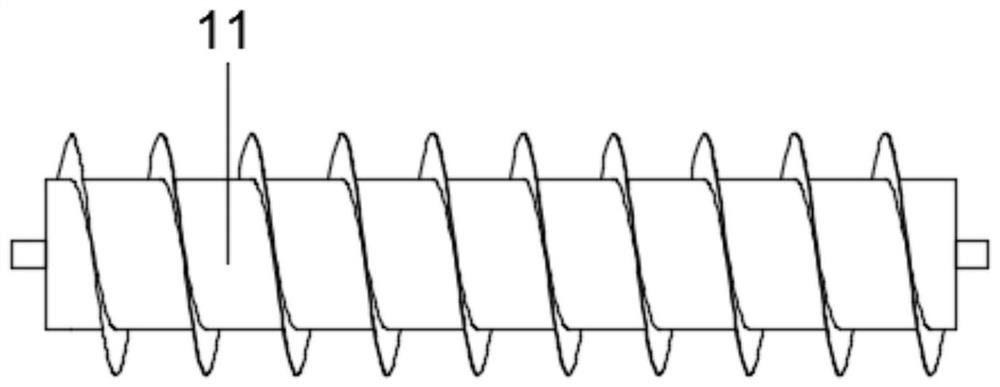

[0037] as attached figure 1 To attach Figure 8 Shown:

[0038]The present invention provides gravity settling separation equipment for chemical mixed liquids, including: a cylindrical cylinder 1, a square hole 3, a cleaning structure 4, a cylindrical rod 401, a motor A5, a water inlet pipe 6, an adjustment baffle 601, a speed brake A7, and a speed brake B8 , Outlet pipe A9, rectangular iron 10, circular groove 1001, rectangular groove 1002, circular hole 1003, guide roller 11, baffle 12, outlet baffle 1201, gear 13, motor support plate 14, motor B15, Chain 16, collection box 17, outlet pipe B18 and conical protrusion 19; a square barrel 2 is welded on the left end of the cylindrical barrel 1, and the cylindrical barrel 1 communicates with the square barrel 2; the front side of the outer wall of the cylindrical barrel 1 is provided with a A square hole 3; a cleaning structure 4 is arranged in the cylindrical barrel 1, and the cleaning structure 4 is rotationally connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com