Buffer type highway guardrail for hillside dangerous road

A highway guardrail and buffer belt technology, applied in the directions of roads, roads, road signs, etc., can solve the problems of passenger impact force, rushing out of the road, passenger danger, etc., and achieve the effect of improving the effect of deceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

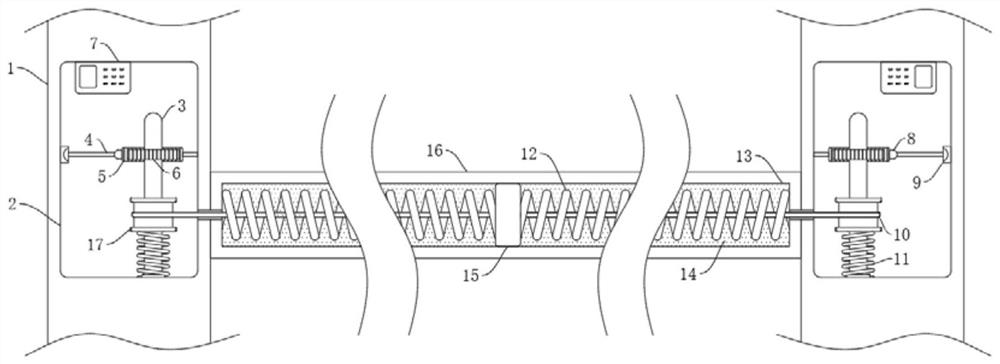

[0025] refer to figure 1 , a buffer type highway guardrail for dangerous roads near mountains, comprising two railings 1, the opposite side walls of the two railings 1 are fixedly connected with a buffer belt 16, the buffer belt 16 is made of carbon fiber material, carbon fiber has a soft texture but It has the characteristics of high strength, and when the vehicle collides with the buffer belt 16, the buffer belt 16 can be bent and deformed.

[0026] The buffer belt 16 and the two railings 1 are jointly provided with a buffer mechanism. The buffer mechanism includes an installation cavity 13 arranged inside the buffer belt 16. The inner wall of the installation cavity 13 is fixedly connected with a fixed plate 15, and the two side walls of the fixed plate 15 are fixedly connected with Traction rope 10.

[0027] Both railings 1 are provided with control chambers 2, and the bottoms of the two control chambers 2 are rotatably connected with rotating rods 3, and the side walls o...

Embodiment 2

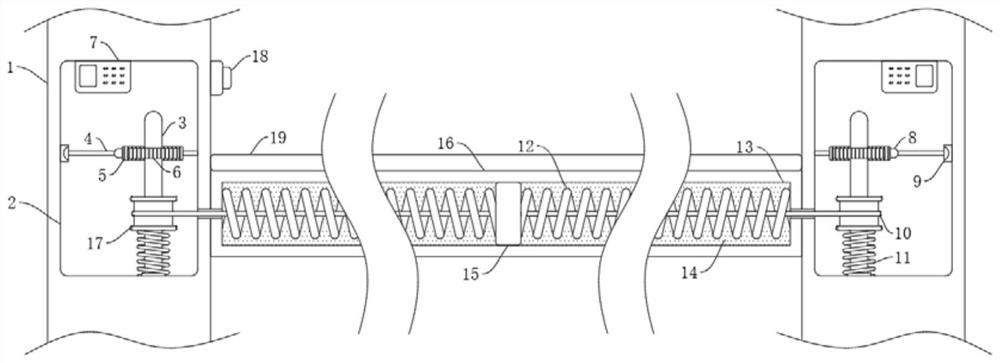

[0034] refer to figure 2 , a buffer type highway guardrail for dangerous roads near mountains. The side wall of the buffer belt 16 is provided with a light strip 19, and one of the side walls of the railing 1 is provided with a light control switch 18, which can be automatically opened at night, so that the circuit conduction, the light strip 19 and the light control switch 18 are electrically connected to one of the power sources 7 .

[0035] In this embodiment, at night, the light control switch 18 can be automatically turned on, and the light strip 19 is energized to emit light. The light strip 19 is arranged along the direction of the buffer strip 16, which can facilitate the driver to notice the position of the buffer strip 16, and then clearly Understand the changes of the route, and prevent accidents due to the driver's inability to see the change of the route on the sharp curve section or multi-curve section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com