Gravitational settling type gas-liquid separation method

A technology of gas-liquid separation and gravity sedimentation, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low gas-liquid separation efficiency and low cost, and achieve high-efficiency gas-liquid separation capabilities and manufacturing costs Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

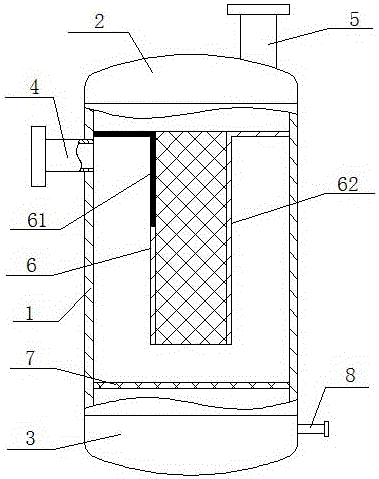

[0024] Gravity sedimentation gas-liquid separation method, such as figure 1 and figure 2 shown, including steps:

[0025] Step 1) By installing an upper end cap 2 on the upper end of the cylinder body 1 and a lower end cap 3 on the lower end of the cylinder body 1, the gas-liquid mixture enters the separator from the inlet pipe 4 provided on the cylinder wall near the upper end of the cylinder body 1.

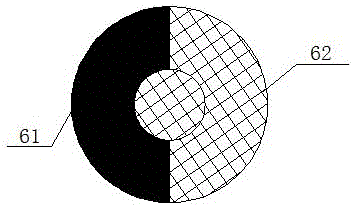

[0026] Step 2) A filter element 6 is provided in the cylinder body 1, the filter element 6 includes a flow guide part 61 and a filter part 62, the flow guide part 61 is made of an air-tight material, and the flow guide part 61 is located near the filter element 6 One side of the inlet pipe 4, after the gas is filtered, is discharged through the outlet pipe 5 provided on the upper end cover 2.

[0027] Step 3) The separated liquid is discharged through a drain pipe 8 arranged at the lowest point of the bottom surface of the lower end cover 3 .

[0028] In oil exploitation, t...

Embodiment 2

[0030] This embodiment is a further improvement on the above-mentioned embodiment, as figure 1 and figure 2 As shown, in this embodiment, the section of the filter element 6 is T-shaped, the horizontal part of the filter element 6 is detachably connected to the inner wall of the cylinder 1, and the upper half of the horizontal part and the vertical part of the filter element 6 near the side of the intake pipe 4 The section constitutes a diversion part 61, and the filter element 6 with a T-shaped cross section is convenient for installation and fixing in the cylinder body 1, and can facilitate the flow of the gas-liquid mixture. The bottom of the filter element 6 in the cylinder body 1 is detachably provided with a filter screen 7, which is used to filter impurities in the gas-liquid mixture, so as to facilitate further processing of the liquid part in the gas-liquid mixture. The filter screen 7 and the inner wall of the cylinder body 1 can be separated. The connection is dis...

Embodiment 3

[0032] This embodiment is a further improvement on the above-mentioned embodiment, as figure 1 and figure 2 As shown, in this embodiment, the upper end cap 2 and the lower end cap 3 are threadedly connected with the cylinder body 1, the connection between the upper end cap 2 and the lower end cap 3 and the cylinder body 1 is coated with sealant, and the air inlet pipe 4 is tightly connected with the cylinder body 1 , the air outlet pipe 5 is in sealing connection with the upper end cover 2, and the liquid discharge pipe 8 is in sealing connection with the lower end cover 3. The upper end cover 2 and the lower end cover 3 are threadedly connected, which is convenient for the maintenance of the present invention, and the above-mentioned connection nodes are sealed to ensure the airtightness of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com