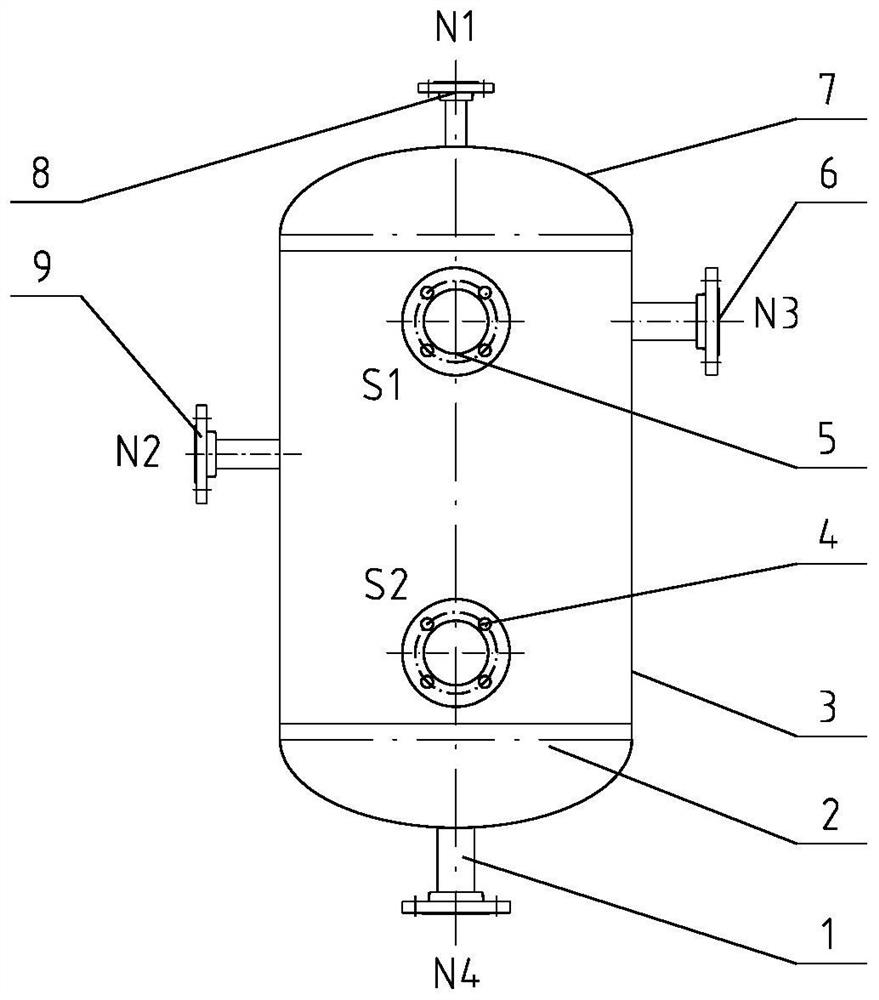

A vertical oil-water separation device

An oil-water separation device, vertical technology, applied in the field of liquid-liquid phase separation, can solve the problems of small amount of oily wastewater treatment, short service life of the device, low separation efficiency, etc., achieve low energy consumption and pressure loss, simple structure, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

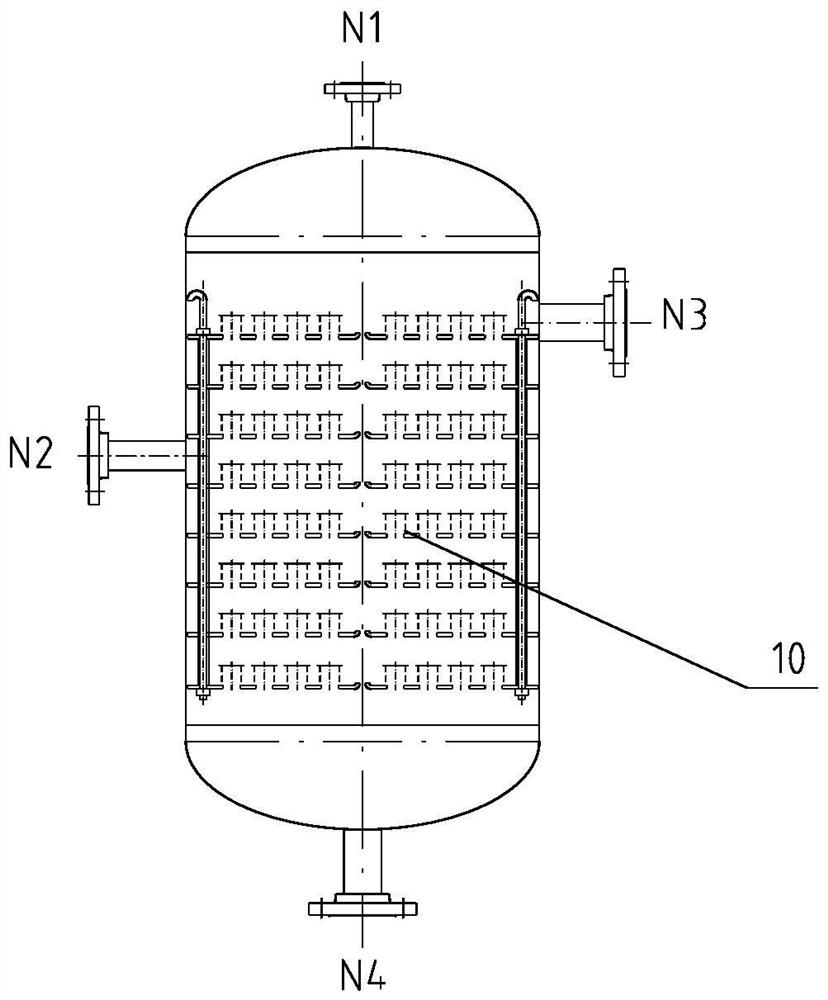

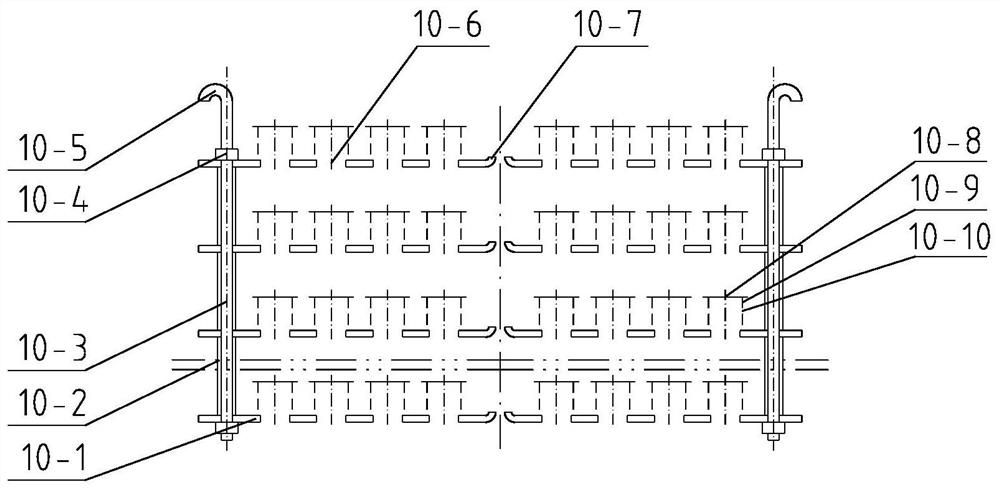

[0042] Embodiment: In this embodiment, the diameter of the cylinder body 3 is 500 mm, and the length of the cylinder body 3 is 800 mm. Four support ribs 10-11 are welded inside the cylinder body 3 at a position 2100mm away from the lower head, and an oil-water separation assembly 10 is installed above the support ribs 10-11. The oil-water separation assembly 10 includes eight bottom plates 10-1, the distance between two adjacent bottom plates 10-1 is 70 mm, the outer diameter of the bottom plates 10-1 is 796 mm, and the thickness is 4 mm. There is a guide hole 10-7 with an upwardly protruding tongue 10-7-1 at the center of the bottom plate 10-1, and several round holes 10-6 are evenly opened around the guide hole 10-7, and the round holes 10-6 are arranged The method is to arrange them in a circle around the center of the base plate 10-1, and the diameter of the base plate circular hole 10-6 is 25mm.

[0043] A cap 10-9 is provided above the base plate round hole 10-6, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com