Horizontal electrical dust collector integrating gravity and cyclone dust removal

A technology for cyclone dust removal and electrostatic precipitator, which is applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of easy entry of outside air into the dust collector, poor working effect of cyclones, and small dust pitch. Low friction, improved work efficiency, and small dust pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

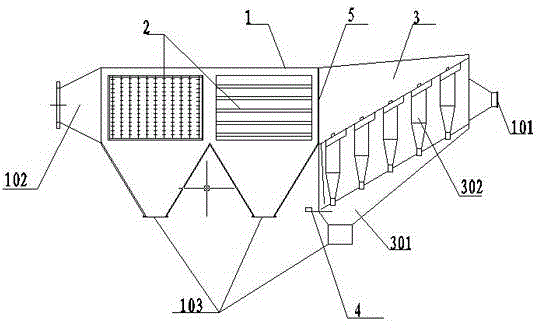

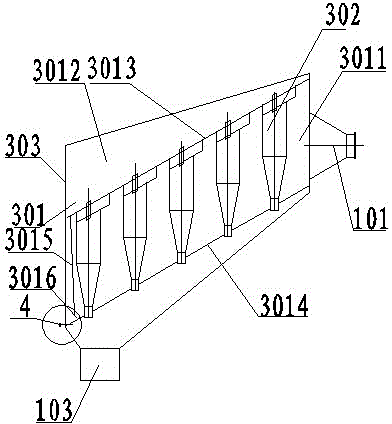

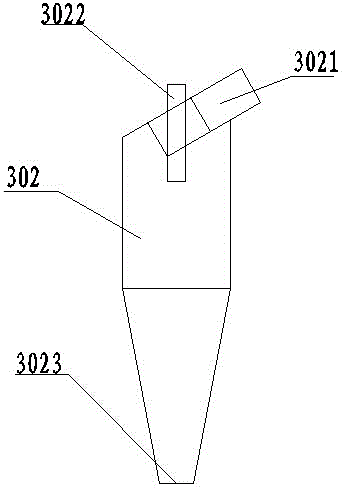

[0025] As shown in the figure, a horizontal electrostatic precipitator integrating gravity and cyclone dust removal includes a housing 1 with an air inlet 101 and a clean gas outlet 102. Gravity cyclone dust removal device 3 and at least one group of electric dust removal device 2, between the air outlet 303 of gravity cyclone dust removal device 3 and the air inlet of electric dust removal device 2, an air equalizer 5 is arranged, between said electric dust removal device 2 and The gravity cyclone dedusting device 3 is provided with ash outlet 103, and the gravity cyclone dedusting device 3 includes a gravity settling chamber 301 and a cyclone 302 arranged in the gravity settling chamber, and the gravity settling chamber 301 is formed by the cyclone. The plate 3013, the lower flower plate 3014 of the cyclone and the damping plate 3015 divide the cavity in the gravity settling chamber 301 into a primary gravity settling chamber 3011 and a secondary gravity settling chamber 3012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com