Treatment method for sludge reduction

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., to achieve high concentration, increase sludge reduction, and reduce operating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

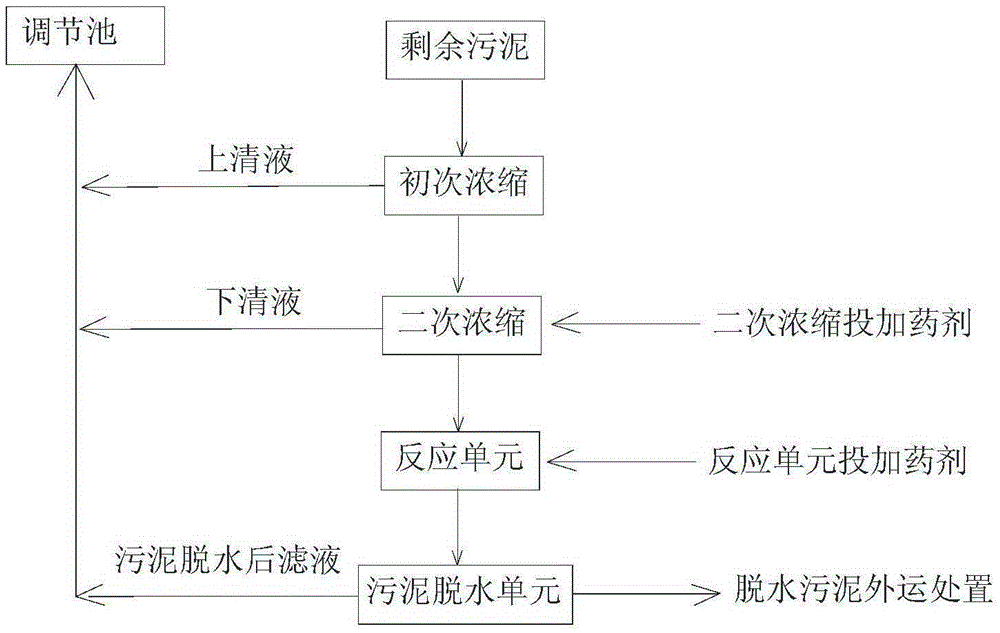

Embodiment 1

[0027] The excess sludge is discharged from the secondary sedimentation tank of a sewage treatment station in a factory, and the sludge concentration is 7-9g / L. The excess sludge enters the sludge concentration tank and stands still for 15 hours for initial concentration. The supernatant is returned to the sewage station for adjustment After the initial thickening, the volume of the sludge is reduced to 35% of the original volume; add polyacrylamide with a sludge volume of 3‰ and 1% hydrogen peroxide to the sludge after the initial concentration, and float for 30 minutes, and muddy water can be observed Stratification is rapid and the interface is clear. After the air flotation is completed, the supernatant is discharged to the regulating tank, and the sludge volume is reduced by about 50%. The sludge after two times of concentration is then reacted through the reaction unit. The control conditions of the reaction are: add Adjust the pH to 5 with sulfuric acid, heat to 90°C wit...

Embodiment 2

[0033]The excess sludge discharged from the secondary sedimentation tank of the sewage treatment station of a daily chemical product production factory has a sludge concentration of 8-10g / L. The excess sludge contains more organic substances and refractory substances. The excess sludge is pumped into the After the sludge concentration tank was left standing for 16 hours, the initial concentration was carried out, and the supernatant was returned to the adjustment tank of the sewage station. After the initial concentration, the sludge volume was reduced to 40%; Acrylamide and ozone were used for air flotation, and the air flotation was carried out for 40 minutes until the stratification was stable. After the air flotation was completed, the volume of the sludge was reduced by about 60%, and the supernatant was discharged to the adjustment tank at the same time; Entering the reaction unit, the control conditions of the reaction are: adding sulfuric acid to adjust the pH to 1, pas...

Embodiment 3

[0039] The secondary sedimentation tank of an urban sewage treatment plant discharges excess sludge with a sludge concentration of 5-9g / L. The excess sludge enters the sludge concentration tank and is left for 15 hours for initial concentration. After the initial concentration, the supernatant is refluxed To the sewage station regulating tank, the sludge volume is reduced to 30%; add 3‰ of the sludge volume of polyacrylamide and 1% hydrogen peroxide to the sludge after the initial concentration, and float for 30 minutes, and the sludge moisture can be observed After the air flotation is completed, the volume of the sludge is reduced by about 50%, and the supernatant is discharged to the adjustment tank; the sludge after twice concentration enters the reaction unit, and the control conditions of the reaction are: adding hydrochloric acid to adjust the pH To 1, heat to 80°C with steam and keep it warm, add sodium hypochlorite with 7% of the sludge mass after the initial concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com