Waste fly ash treatment system and treatment process

A treatment system and garbage fly ash technology, applied in the direction of filtration treatment, sedimentation treatment, multi-stage water treatment, etc., can solve pollution and other problems, achieve simple process control, reduce high costs, and solve pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

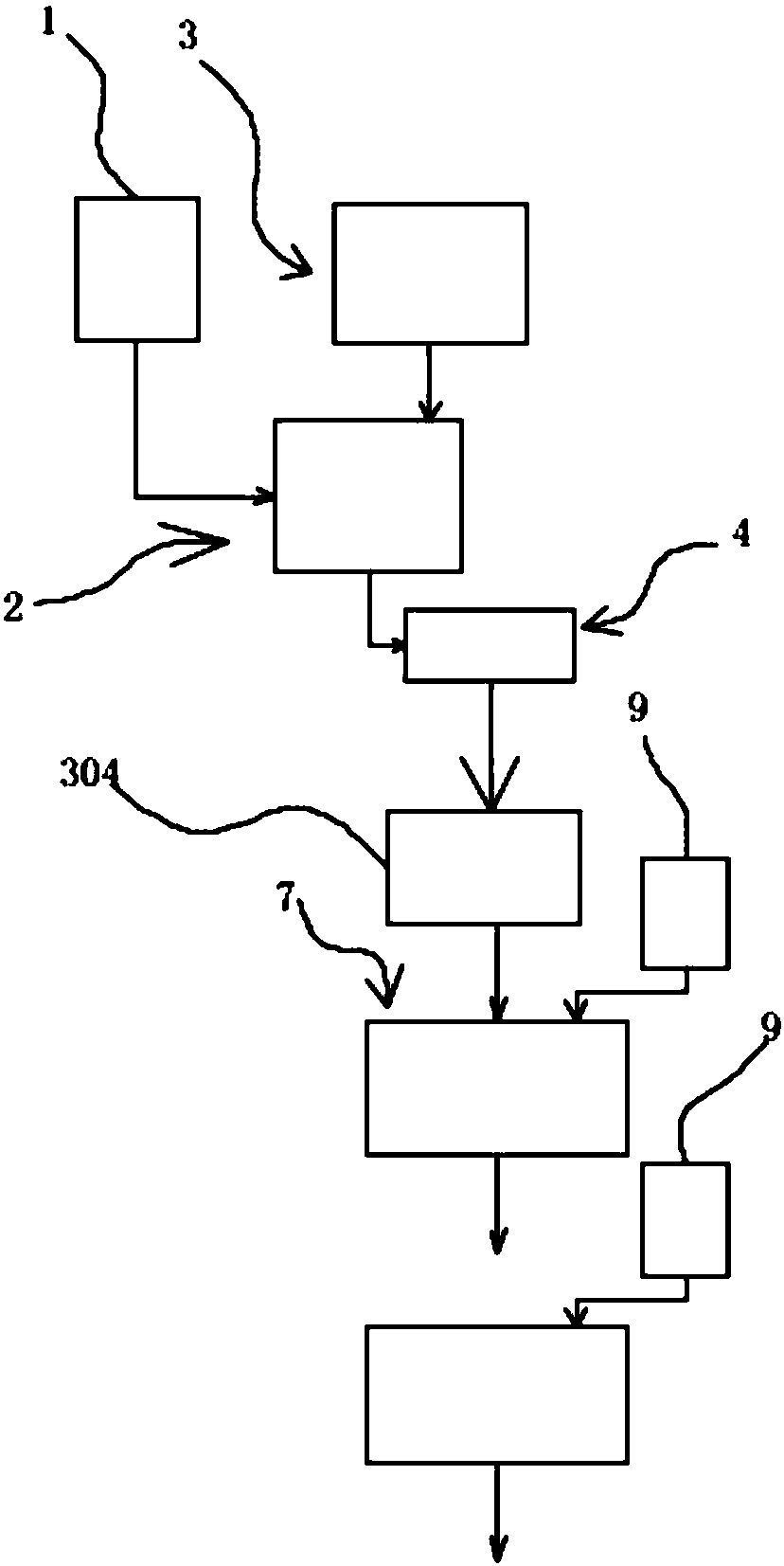

[0059] A garbage fly ash treatment system, such as figure 1 As shown, it includes two parts: the fly ash washing system and the wastewater treatment system; the fly ash is firstly washed by the fly ash washing system, and then the solid-liquid separation is carried out, and then the separated solid sludge and wastewater are treated separately;

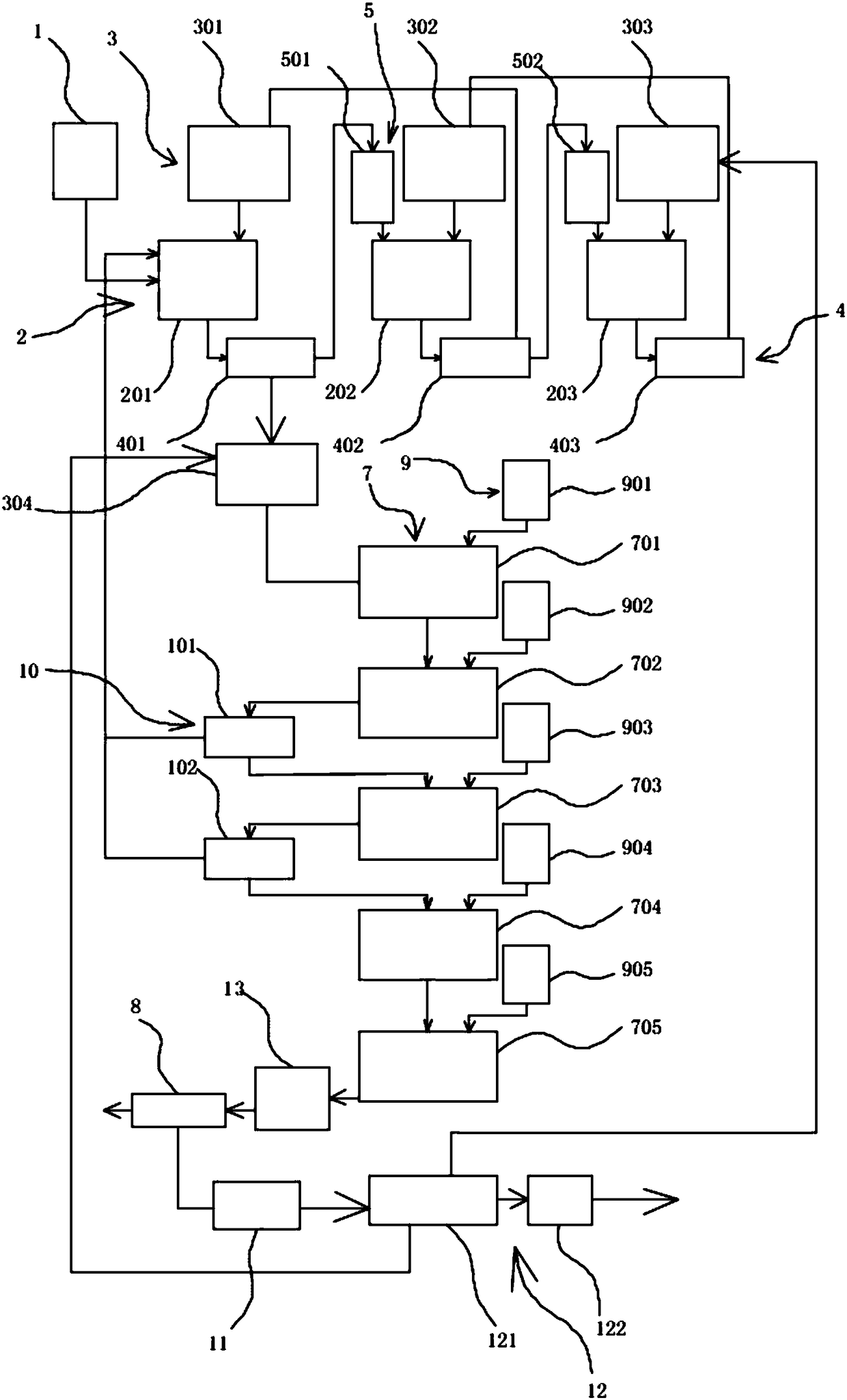

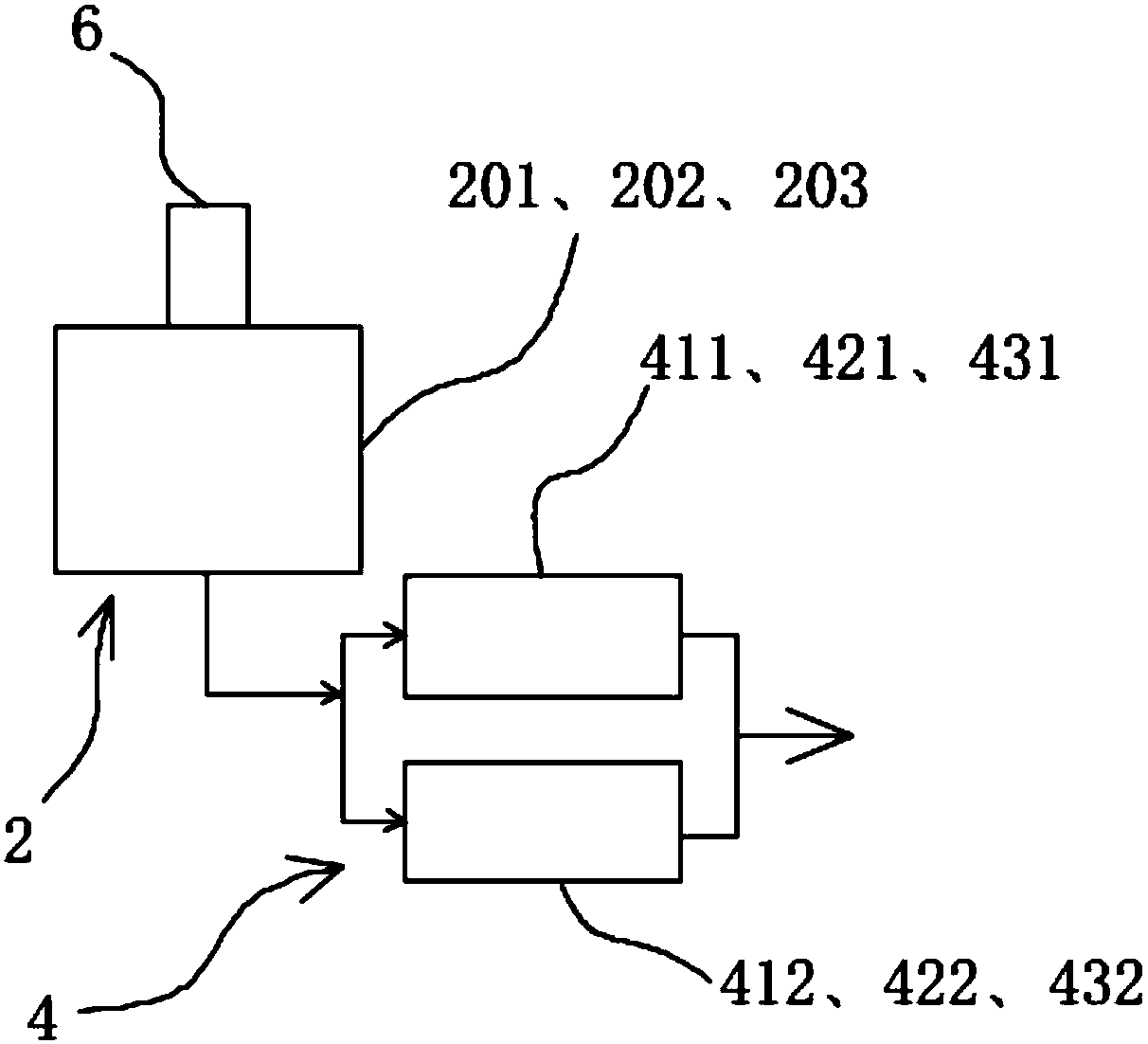

[0060] specific as figure 2 and image 3 As shown, as follows:

[0061] The fly ash washing system in the garbage fly ash treatment system adopts a multi-stage cleaning pool 2 arranged in sequence and cooperates with a multi-stage washing filter press 4. The fly ash washing system is provided with a reaction storage pool for storing the washed waste water 304; the wastewater stored in the reaction storage tank 304 is used for further treatment in the subsequent wastewater treatment system; the water washing filter press 4 separates the mixed solution obtained from the cleaning tank 2 of each stage;

[0062] The waste water treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com