Mobile station and methods for diagnosing and modeling site specific effluent treatment facility requirements

a mobile station and effluent treatment technology, applied in the field of effluent treatment, can solve the problems of not all effluent treatment requires the same technology, affects ongoing operations financially and in terms of operational continuity, foolish planning and building a facility, etc., and achieves the effect of improving operational continuity and reducing financial risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1601

[0157]The higher air and / or plasma-gas pressure provides adequate sealing action between the active membrane side and the coiled feed path. The thickness of the coiled feed path in relation to membrane sleeve 1611 diameter is in the range of 1:5 to 1:500. Coil feed path length in relation to sleeve 1611 length is in the range of 2:1 to 200:1. As maybe appreciated membrane cost savings are realized while ease of membrane exchange or replacement and large membrane area are provided. Visual inspection of bubble generation is allowed through the clear outer housing body enabling better bubble control. Embodiment 1601 maximizes efficiency due to integrated non-plugging inline mixing (no added static inline mixing device is needed) and compact design.

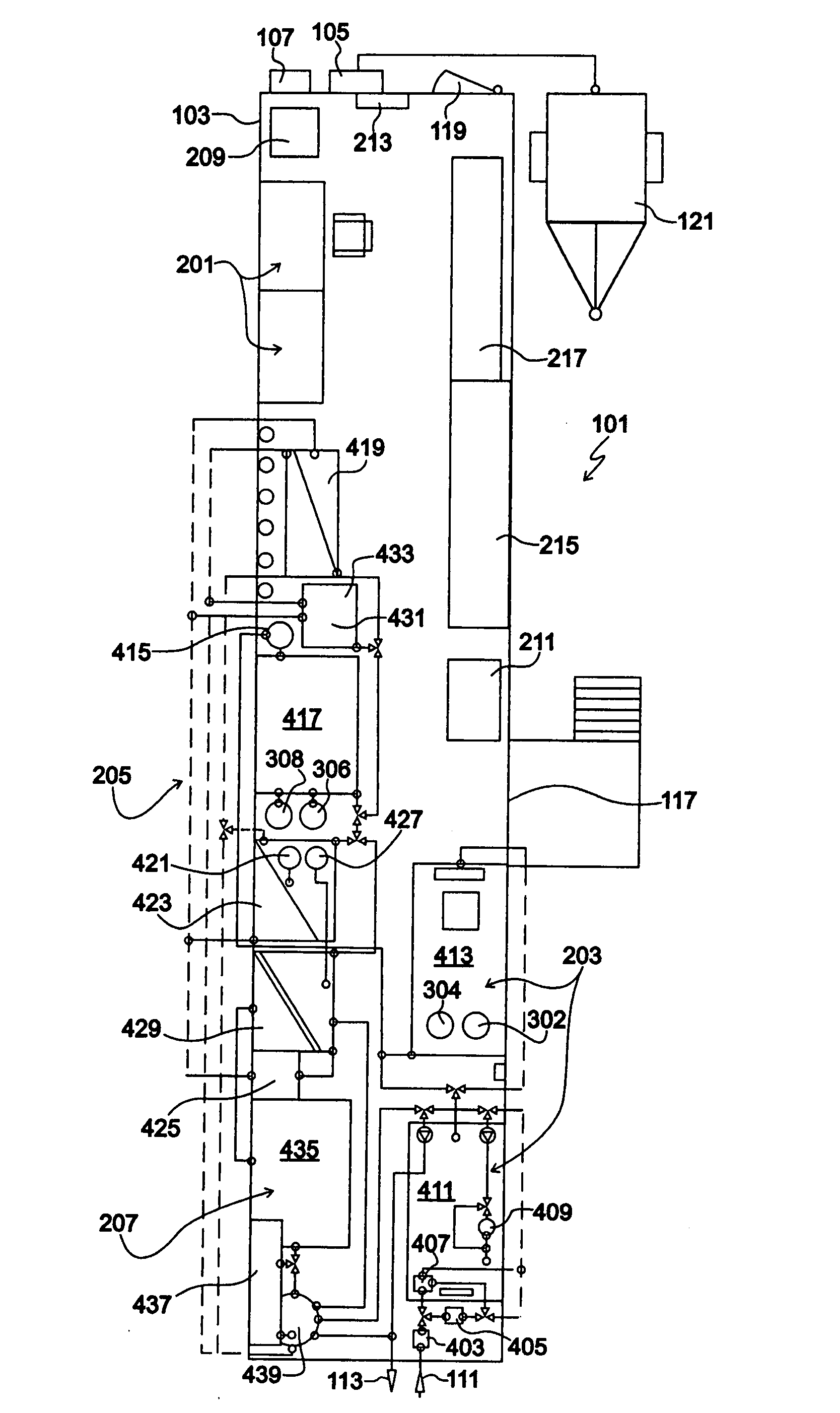

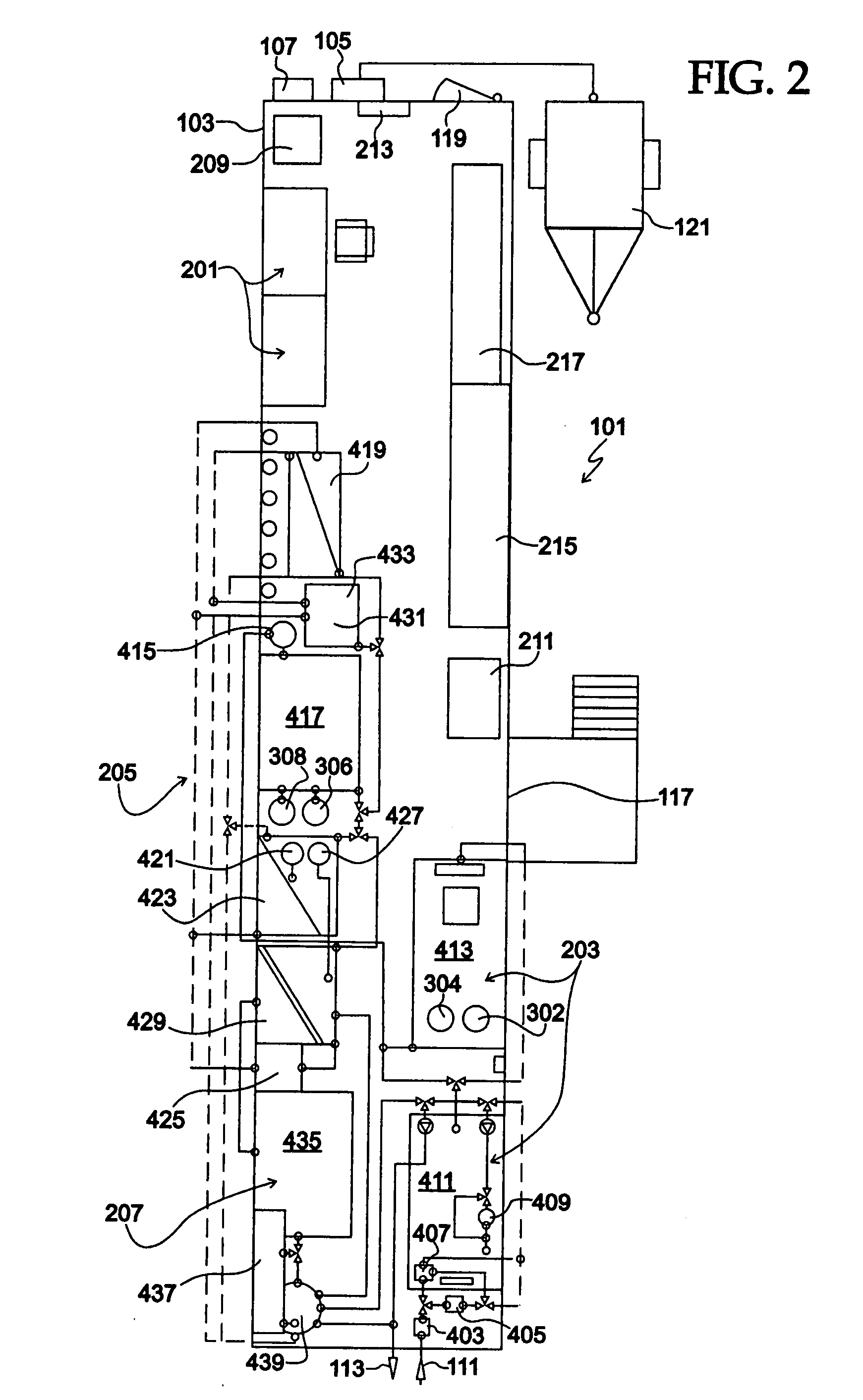

[0158]FIG. 17 shows a second embodiment 1701 of membrane aeration apparatus 803 of second pre-treatment suite 413 (similar elements retaining numbering from prior occurrence). In this second ODE variation, tubular or capillar membrane bundles...

third embodiment

[0169]While shown utilizing the emitter 1803 of the third embodiment, this embodiment can be employed also with photo (UV) initiated air ionization technology. If radioactive initiated air ionization is employed, the positively charged α-particles will deflect towards the negatively charged electrical field. The frequency controlled alternating deflection of the α-particles takes place primarily within the upper portion of the ionization chamber. This alternating deflection provides additional collision potentials with the continual incoming large number of neutral air molecules, thus slowing the recombination of positive and negative ion pairs prior to exposure to the contaminated effluent.

[0170]The alternating current flow provides an enhanced distribution environment for the diffusively aerated ionized air / gas for balancing the surface charge of particles in the feed water solution thus removing or reducing the electrical repulsive charge on the particles. This hydrodynamic mixin...

first embodiment

[0255]In accordance with another aspect of this invention, a high frequency membrane separation apparatus and method utilizable with membrane systems of this invention is shown in FIGS. 33a and 33b. This invention relates to apparatus and methods for fluid filtering utilizing membrane separation (for example nanofiltration and / or reverse osmosis filtration) that combines vibratory shear techniques with adjustable crossflow techniques. This and further embodiments of the high frequency membrane separation apparatus and methods (set forth hereinafter) are particularly well adapted to treatment stages 419, 423, 429 and / or 433 when membrane treatment options are applied (generically referred to hereinafter as membrane treatment systems).

[0256]High frequency membrane separation herein refers to vibrating, oscillatory motion of the membrane support structure. Vibration direction is perpendicular to the floor of station 101 for gravity assisted membrane separation systems. The vibration cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| generator power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com