Pig manure sewage treatment device and method

A sewage treatment device and pig manure technology, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, animal husbandry wastewater treatment, etc. Demand, limited treatment capacity and other issues, to achieve the effect of high sewage treatment efficiency, green and environmentally friendly treatment process, and avoid gas volume attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

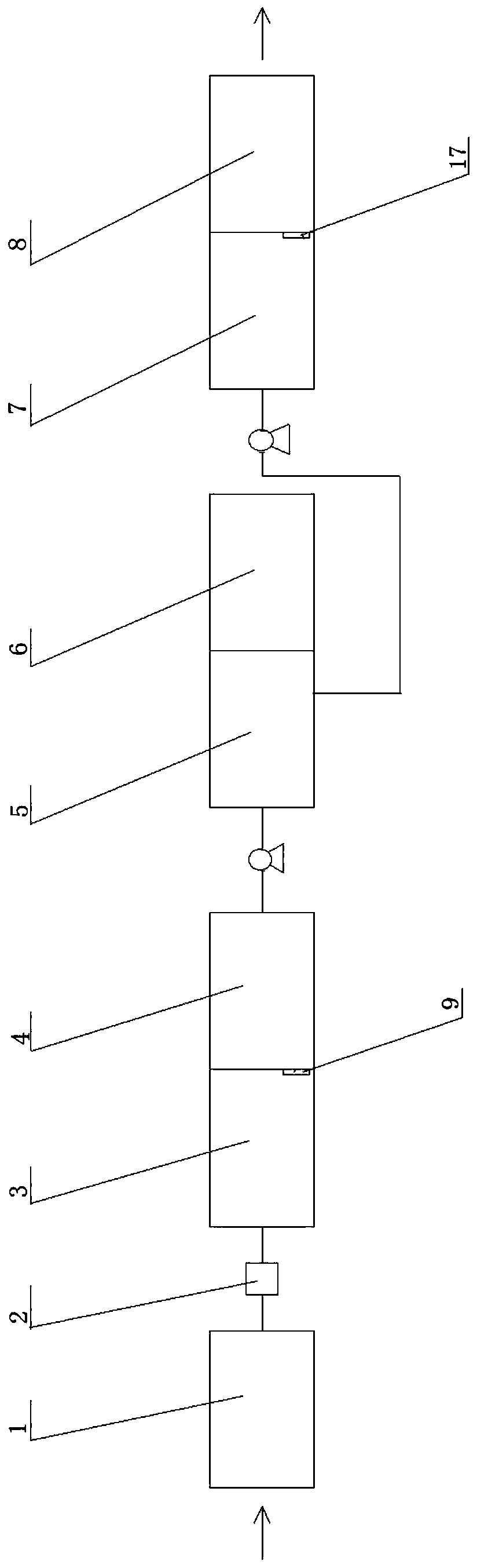

[0044] Embodiment 1, with reference to figure 1 , a pig manure sewage treatment device, comprising an anaerobic tank for collection, an anaerobic tank for primary filtration, an anaerobic tank for secondary filtration, an aerobic tank, a primary sedimentation tank, and a secondary sedimentation tank arranged in sequence;

[0045] There is a dry-wet separator between the collection anaerobic tank and the first-stage filter anaerobic tank. The feed port of the dry-wet separator leads into the collection anaerobic tank through the feed pipeline, and the liquid outlet of the dry-wet separator passes through The outlet pipeline leads to the primary filter anaerobic tank;

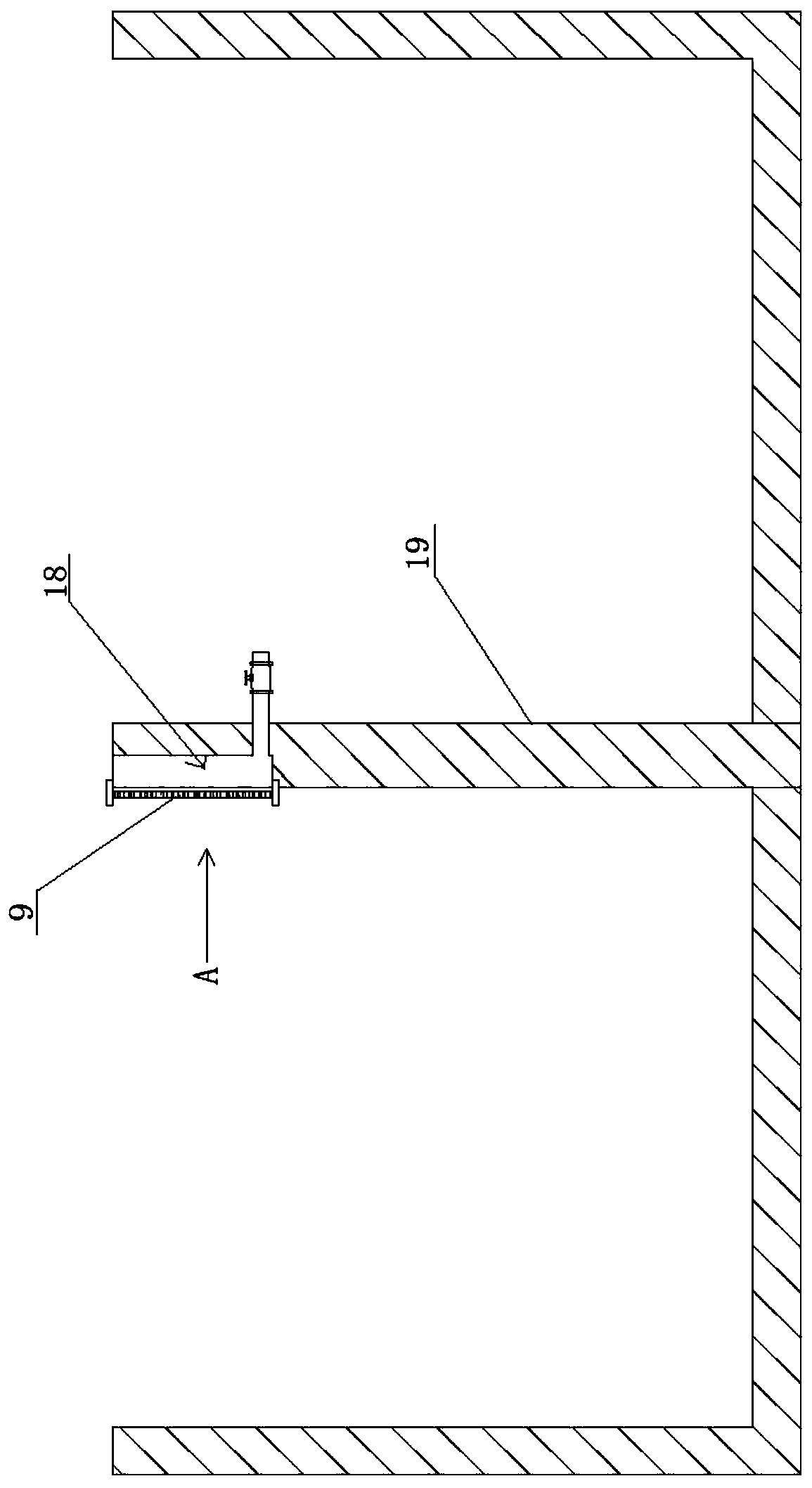

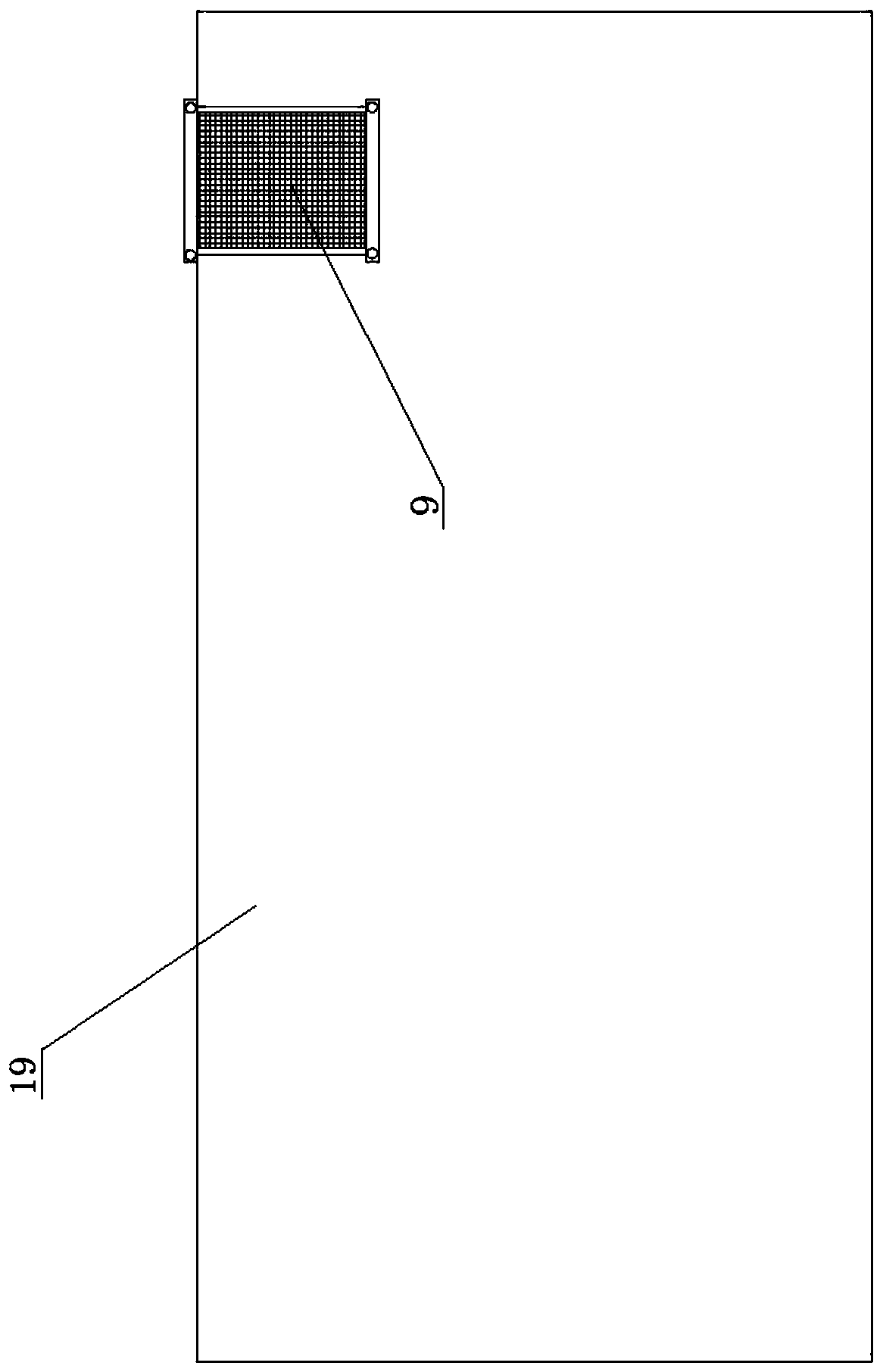

[0046] refer to figure 2 with image 3 , the primary filter anaerobic pool and the secondary filter anaerobic pool are connected together and set up with a partition wall, there is a first partition wall between the primary filter anaerobic pool and the secondary filter anaerobic pool, and the first partition ...

Embodiment 2

[0050] Embodiment 2, in the pig manure sewage treatment device described in Embodiment 1: the aperture of the filter screen is 0.425mm. refer to Figure 4 , a heating rod is installed in the aerobic pool, a thermal insulation mechanism is provided on the aerobic pool, the thermal insulation mechanism includes a sun shed and a thermal insulation cloth layer, the sunlight shed is fixedly installed directly above the aerobic pool, and the thermal insulation cloth layer covers the aerobic pool. The temperature of the sewage in the aerobic pool is maintained between 10-60° C. by using the sunshine shed 14 and the thermal insulation cloth layer 11 , and this temperature range can make microorganisms multiply rapidly. When the temperature is too low in winter, the heating rod 10 is used to locally heat the aerobic pool 5, so that the temperature of the sewage in the aerobic pool is maintained between 10-60°C.

Embodiment 3

[0051] Embodiment 3, in the pig manure sewage treatment device described in Embodiment 1 or 2: the aperture of the filter screen is 0.3mm. The thermal insulation cloth layer is composed of an inner thermal insulation layer and an outer waterproof layer; the heating rod is provided with a waterproof sleeve, and the bottom of the waterproof sleeve is fixedly connected to the mounting seat of the heating rod, and the power supply line of the heating rod Pass through the waterproof casing. A large amount of foam can be produced when the aerobic pool 5 explodes, and the thermal insulation cloth layer 11 can also play the effect of eliminating the foam when covered on the aerobic pool 5; Wires are corroded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com