Special sealed feeding device for hazardous waste incinerator and feeding method of feeding device

A technology of hazardous waste and feeding devices, applied in the direction of combustion methods, incinerators, combustion types, etc., can solve problems such as hidden safety hazards of feeding materials, and achieve the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

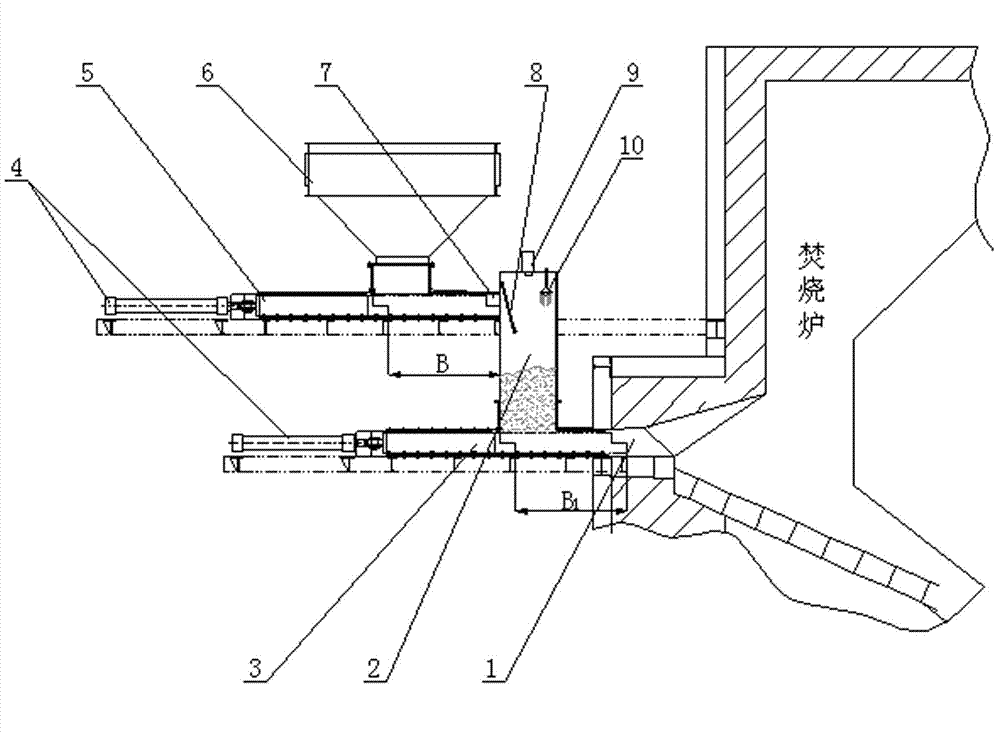

[0010] Refer to attached figure 1 , The special sealed feeding device for hazardous waste incinerator includes a hopper (6), an oil cylinder (4), a primary pushing body (5), a feeding channel (7), a hook-type flap gate (8), and a sealed silo ( 2), secondary pusher body (3), feed port (1), monitoring camera head (9), sprinkler fire extinguishing device (10). The hopper (6), primary pusher body (5), feed channel (7) and hook-type flap gate (8) are located at the upper left part of the sealed silo; the second-stage pusher body (3), feeder The mouth (1) is located at the bottom of the sealed silo; the monitoring camera head (9) and the sprinkler fire extinguishing device (10) are located at the top of the sealed silo.

[0011] The monitoring camera monitoring head (9) adopts a commercially available needle-empty monitoring camera.

[0012] The sprinkler fire extinguishing device adopts a commercially available duckbill type sprinkler fire extinguisher.

[0013] The special seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com