Method and apparatus for continuous preparation of carbon nanometer tube material from coal

A technology of carbon nanotubes and explosion-proof devices, which is applied in the intersecting field of plasma science and carbon material science, can solve the problem of difficult control of arc and reaction raw material interaction degree, carbon nanotube material quality and quantity limitation, low catalyst utilization efficiency, etc. problems, to achieve the effect of improving the utilization rate of raw materials, reducing the cost of preparation, and reasonable structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

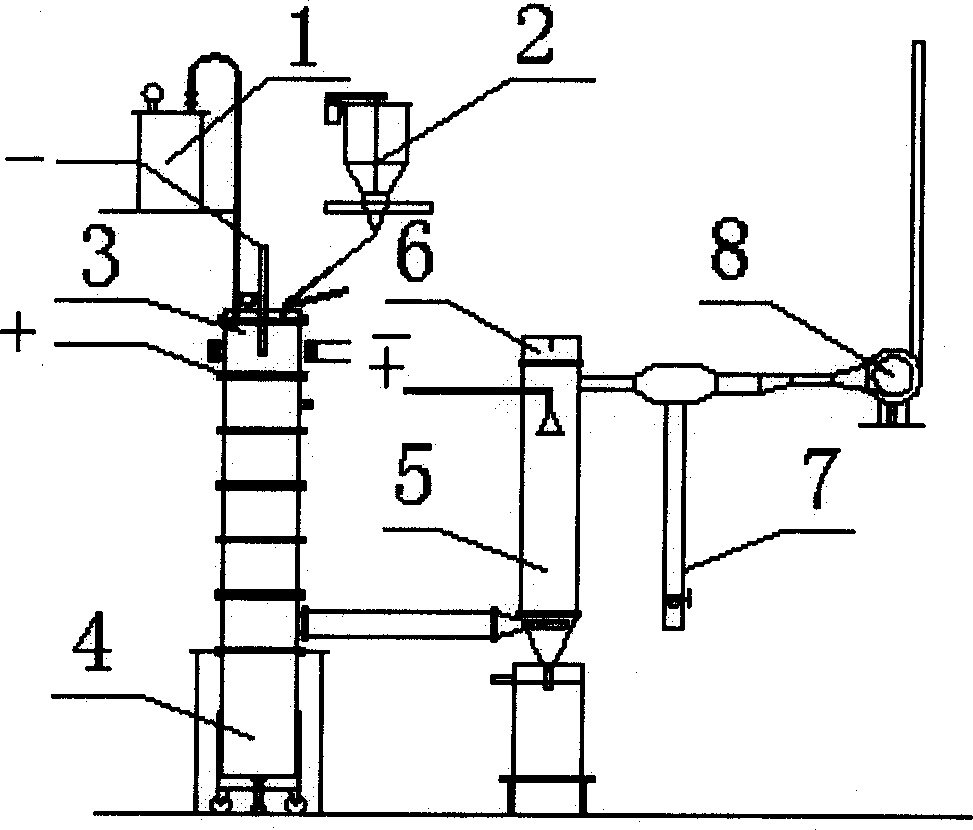

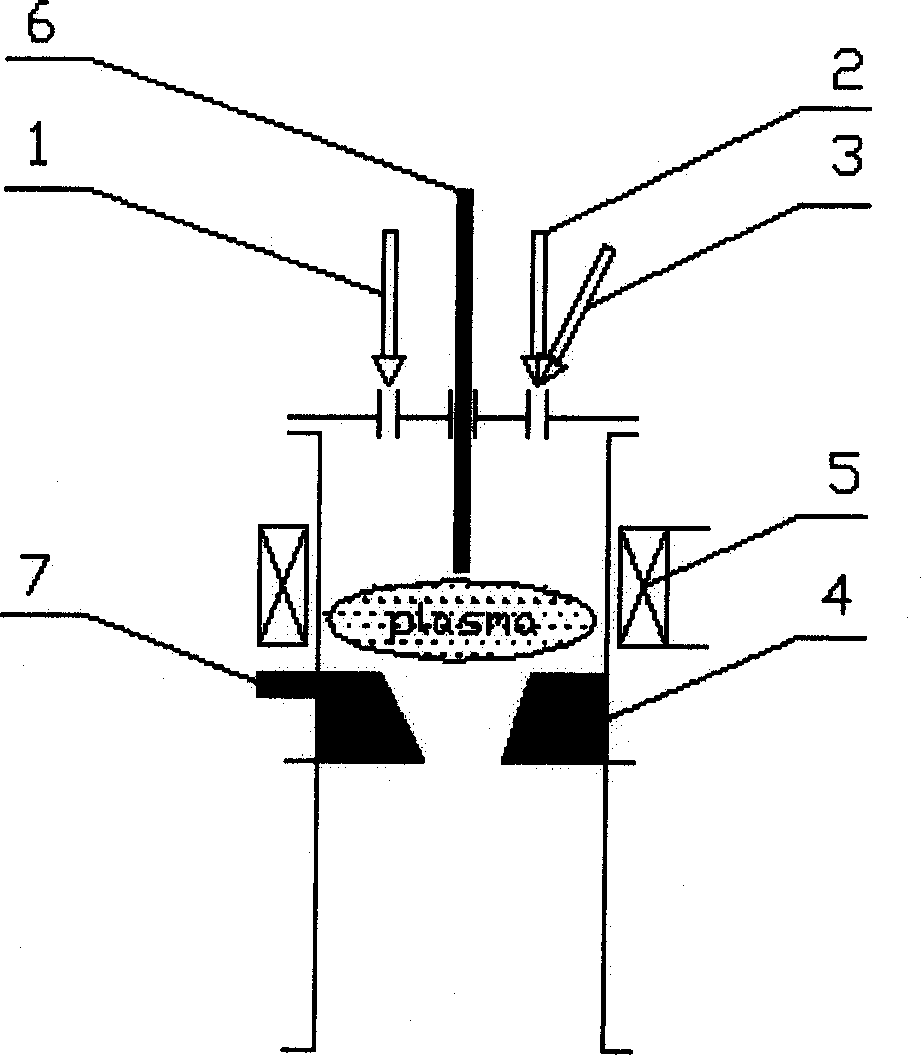

[0023] Water vapor generation and supply system 1, pulverized coal conveying system 2, plasma generator 3, product collector 4, gas cooling and purification system 5, explosion-proof device 6, system pressure regulating system 7 and induced draft fan 8 are in accordance with the following The top and left to right are connected sequentially; the pulverized coal delivery system is connected to the plasma generator through the pulverized coal delivery pipeline, and the steam generation and supply system is connected to the plasma generator through the gas supply pipeline. Taiji coal is used as raw material, and the particle size of coal powder is less than 1 mm. Heat the water in the steam generator, and adjust the pressure of the gas in the steam generator to 1.6 atmospheres; turn on the induced draft fan, adjust the pressure regulation system, so that the pressure of the entire system is at minus 20 millimeters of water column, and turn on the circulating cooling water; then ,...

Embodiment 2

[0025] The connection of the reaction system is the same as in Example 1. Taiji coal is used as raw material, and the particle size of coal powder is less than 0.50mm. Heat the water in the steam generator, and adjust the pressure of the gas in the steam generator to 1.8 atmospheres; turn on the induced draft fan, adjust the pressure regulation system, so that the pressure of the entire system is at minus 20 millimeters of water column, and turn on the circulating cooling water; then , connect the plasma working gas (high-purity nitrogen), and regulate its flow rate to be 2.6 cubic meters per hour; connect the power supply and initiate the arc of the plasma generator, and the electric current of the electric arc is adjusted to 230 amperes, and the voltage of the electric arc is about 250 volts; high-temperature water vapor is introduced, and the flow rate of water vapor is 2.0 kg / hour; the pulverized coal conveying system is connected, and the pulverized coal transportation volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com