Jet nozzle for condensing and devolatilizing synthetic rubber

A technology of jet nozzle and synthetic rubber, which is applied in the direction of injection device, liquid degassing, liquid injection device, etc., can solve the problems of insufficient solvent recovery efficiency, poor coagulation effect of colloidal particles, and influence on devolatization effect, etc., and achieves simple structure, The effect of low manufacturing cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

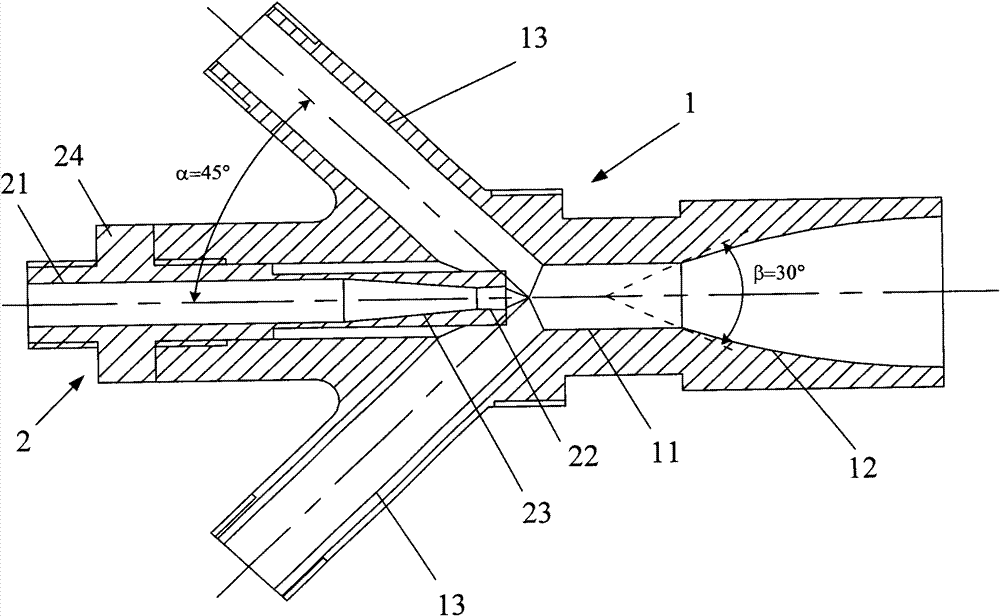

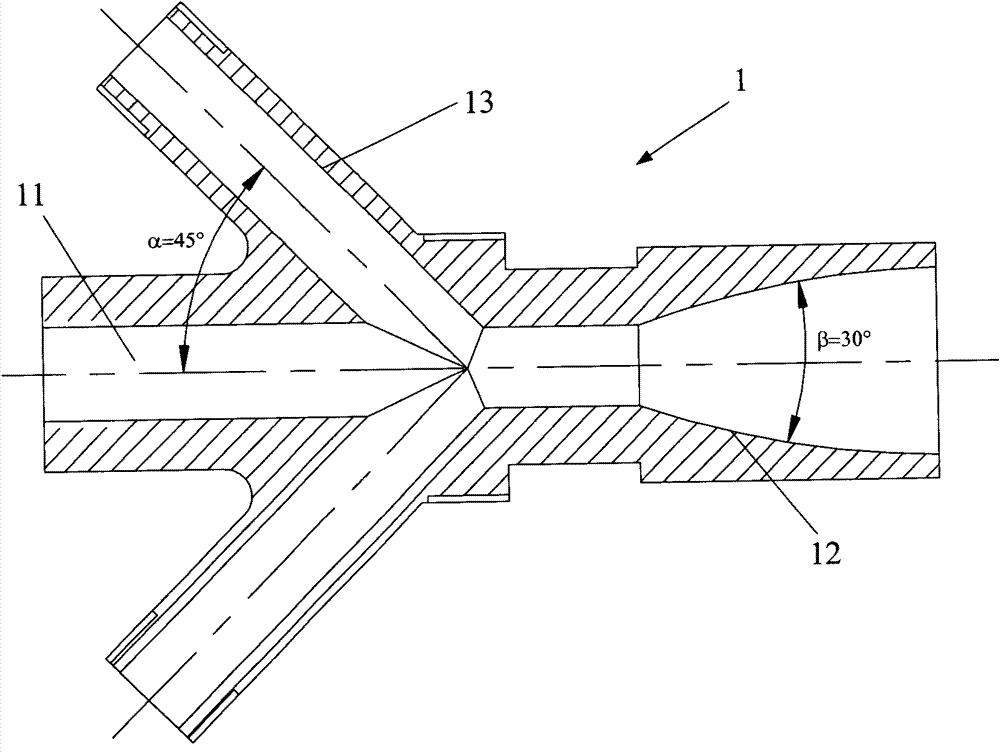

[0028] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0029] In this embodiment, it is assumed that the spraying direction of the glue is from left to right.

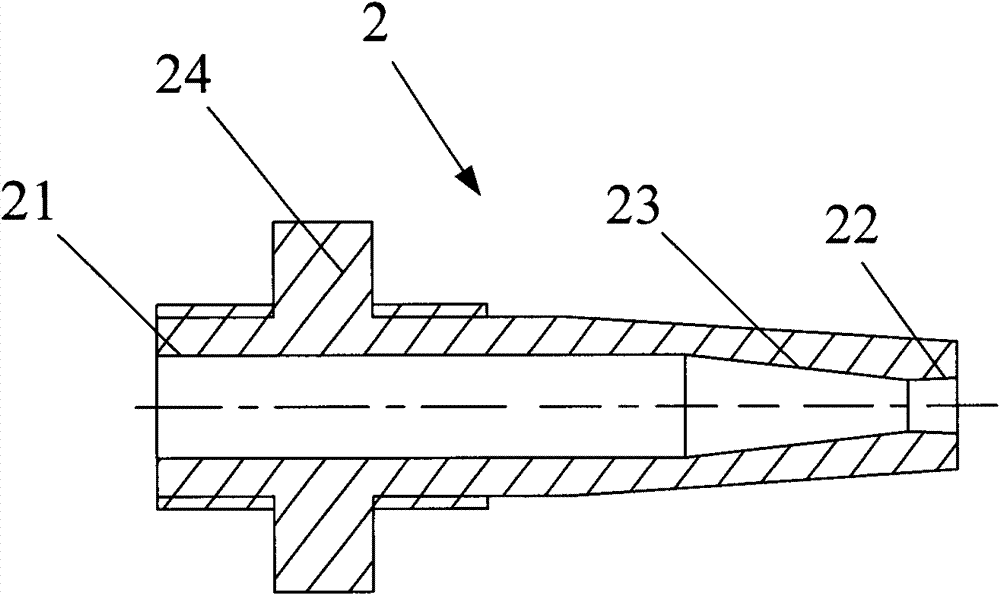

[0030] like figure 1 and 2 As shown, the jet nozzle for synthetic rubber coagulation and devolatilization of the present invention includes a nozzle body 1 , the nozzle body 1 includes a straight throat 11 , and a diffuser nozzle 12 is provided at the right end of the straight throat 11 . The jet nozzle also includes a glue inlet joint 2 , and the glue inlet joint 2 is passed through the straight throat 11 .

[0031] The glue to be reacted (ie, synthetic rubber glue) enters the straight throat pipe 11 from the glue inlet joint 2 .

[0032] like figure 2 As shown, two water inlet pipes 13 are arranged symmetrically on both sides of the nozzle body 1 for high-speed water flow, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com